The GE9X engine has been certified by the USA’s Federal Aviation Administration and the first engines have been delivered, to Boeing for use in its twin-engine Boeing 777X test aircraft.

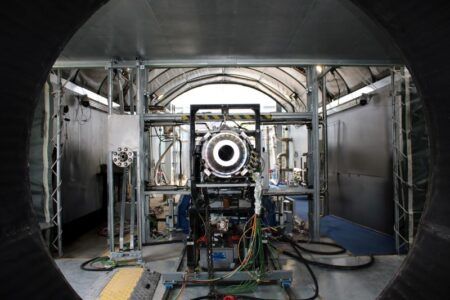

The FAR (Federal Aviation Regulation) Part 33 certification involved eight test engines. GE Aviation engineers subjected the GE9X test engines to just under 5,000 hours and 8,000 cycles to achieve the certification.

The GE9X engine is the most powerful commercial aircraft jet engine (test performance) in the world, as recognized by the Guinness Book of World Records, after it reaching 134,300 lbs of thrust during in July last year.

John Slattery, president and CEO of GE Aviation said, “There is no substitute that can achieve the combination of size, power and fuel efficiency of the GE9X. This engine will deliver unsurpassed value and reliability to our airline customers. I want to congratulate the entire GE9X team and thank Boeing, our partners and suppliers for the collaboration on this incredible achievement.”

The GE9X engine is designed to achieve 10% lower specific fuel consumption (SFC) compared to the GE90-115B and 5% better SFC than any other engine in its class. The engine will also operate with less smog-causing emissions than any other engine in its class.

Karl Sheldon, GE Aviation’s GE9X program general manager said, “The GE9X engine has been through a rigorous and thorough certification and testing process. We are pleased with the performance of the engine, which has been validated through extensive ground and flight testing and are excited to deliver a mature product to operators around the world.”

GE is now continuing to work with Boeing to complete the 777X flight test program and entry into service. Eight GE9X test engines and two test spares have been produced and delivered to Seattle for Boeing’s four 777X test airplanes. Several GE9X production engines have been assembled, and GE Aviation is in the process of completing factory acceptance tests.

GE Aviation is currently conducting 3,000 cycles of additional ground testing on the GE9X engine to support Extended Operations (ETOPS) approval. The GE9X team is also conducting maturation testing to help GE engineers prepare to support the engine in service.

For service and support of its customers, GE has established GE9X engine training courses at its Customer Technical Education Center (CTEC) facility in Cincinnati. A GE9X engine currently at CTEC is being used to develop lean maintenance practices that will be implemented in customer training modules and GE training procedures. Course work includes line maintenance, borescope and boroblend repair procedures, as well as fan stator removal and installation. The CTEC team is also working augmented reality/virtual reality (AR/VR) training courses to supplement the in-person training.

GE has received orders and commitments for more than 600 GE9X engines.

IHI Corporation, Safran Aircraft Engines, Safran Aero Boosters and MTU Aero Engines AG are participants in the GE9X engine program.