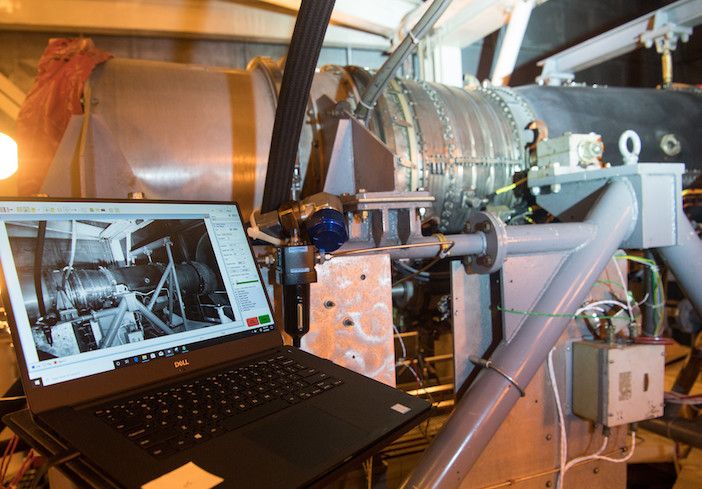

Engineers at the Arnold Engineering Development Complex in Tennessee are trialing the use of high-speed video cameras to detect vibration in engines.

The use of high-speed cameras for vibration analysis is being tested as part of an initiative to use proven non-defense commercial technologies within the US Air Force (USAF). The system, which has been provided by Mechanical Solutions Inc. (MSI) via the Small Business Innovation Research (SBIR) program, has been used at the Aeropropulsion Ground Test Branch at the Arnold Engineering Development Complex (AEDC), part of the Arnold Air Force Base in Tennessee.

MSI developed a non-contact, wide-field vibration sensor for the test cell environment using motion-amplified video technology that generates both numerical and visual output for understanding system vibration.

The kit provided consists of a high-speed, high-resolution camera and software for use during engine testing.The kit was first used during an accelerated mission test in the AEDC’s sea-level test cell SL-3 late last year. To expand upon the knowledge gained during that test, the camera system is now being used during engine runs in the sea-level test cell SL-1.

Seth Beaman, a Naval Air Systems Command aeropropulsion test analyst said, “The major benefit of this system is that it is portable. I can set up pretty much anywhere to see most parts of a test article, unlike engine-mounted instrumentation.

“This system can be used to validate engine mounted data, or analyze the cause of unexplained system vibration.”

The camera mount uses strong magnets allowing it to be mounted on most surfaces in a test cell. The main limitation in placement is the need to isolate the camera from surrounding vibration.

After a recording is made, the software allows the user to select specific vibration frequencies and amplify them in the video. The amplified video allows viewers to more easily see and understand the movement occurring in a system.

“The initial demonstrations of this technology have shown promising results,” Beaman said. “This capability could prove to be very useful in diagnosing or analyzing vibration issues on future test articles or in ground test support equipment.”

A motion amplification camera is also being employed by the Condition-Based Maintenance Team at Arnold Air Force Base to help identify the source of vibrations in equipment, such as motors and compressors.

This article has been edited for style and length and can be read in its original format here.