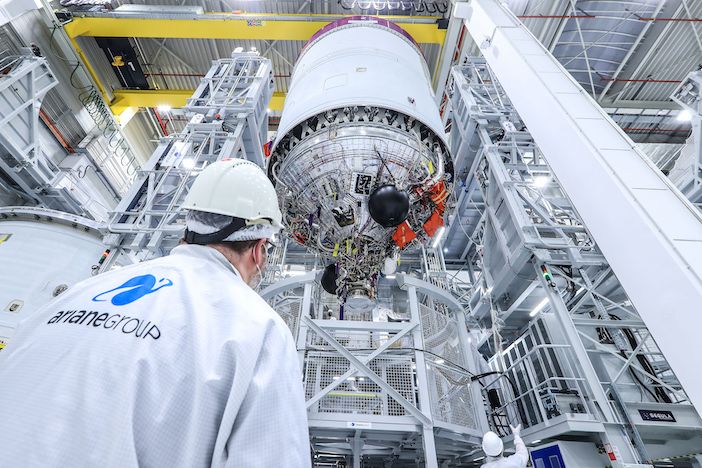

The first complete Ariane 6 upper stage has arrived at a testing site in Lampoldshausen, Germany for hot-fire testing before its planned first launch next year.

The Upper Liquid Propulsion Module (ULPM) is 5.4m (18 ft) in diameter and weighs more than 50 tonnes. This first integrated example of the ULPM, which is called the Hot Firing Model (HFM) has taken two weeks to travel the 600km (370 miles) journey south from the ArianeGroup manufacturing site in Bremen to German Aerospace Center’s (DLR) rocket testing site in Lampoldshausen, near Stuttgart.

Ariane 6 is a heavy lift launch vehicle that will carry payloads of up to 16,000kg into orbit and is the latest in the series of European rockets that first launched during the 1980s. The 60m (200ft) tall rocket, which will weight almost 900 tonnes when launched with a full payload, is the European answer to NASA’s SLS and will be used in two versions, the A62 with two strap-on boosters for lighter payloads and the A64 with four boosters for heavier ones.

The delivery to Lampoldshausen represents a major milestone in the development of Ariane 6, which had its first test flight pushed back to April 2022 last October. The first flight of the launch vehicle had been scheduled for late last year, but was postponed because of Covid-19 related delays and problems with the construction of the launchpad.

The rocket will be launched by the French space agency CNES from a launch pad currently being constructed in Kourou, French Guiana.

Integrated module

This first completed Ariane 6 upper stage is especially important, because it contains a number of key integrated components including the re-ignitable Vinci engine. The upper stage consists of liquid hydrogen and oxygen tanks connected to the Vinci engine and all of the lines, valves, and electronic and hydraulic instrumentation and control systems.

The Vinci engine will enable Ariane 6 to perform complex missions in orbit, such as the positioning of satellite constellation clusters.

The HFM was assembled in October 2020 in Bremen and has successfully undergone all functional tests, including hydraulic, electrical, and avionics.

At Lampoldshausen it will be installed on a specially constructed test bench, P5.2, which was commissioned in 2019. Once the stage is in place under the gantry on the test site, the test campaign will consist of firing up the stage up to four times.

The hot-firing tests are performed in near-vacuum conditions to recreate the environment of space as close as possible. Scheduled to be held by June this year, the tests will qualify the upper stage as “flight ready” as part of the rocket’s qualification process.

Three test articles

Karl-Heinz Servoscoo, chief operating officer of ArianeGroup said, “This first complete upper stage and its transport to the qualification test site underscores the quality of the work done by ArianeGroup and our industrial partners, as well as our determination and our flexibility.

“Another stage to be used for combined tests of the launch system integrating the launch vehicle and launch pad facilities in Kourou is currently being completed in Bremen, while the first upper stage flight model intended for the Ariane 6 maiden flight is undergoing integration.”

Ariane 6 is being developed for the European Space Agency (ESA) by the ArianeGroup, a joint venture between Airbus and Safran and several French and German industrial partners.

Development of Ariane 6 started in the early 2010s, with detailed design and test starting in 2016 when funding was granted by the ESA.

Daniel Neuenschwander, director of space transportation at ESA said, “We have reached another milestone on the Ariane 6 road to flight. Seeing the elements of Ariane 6 coming together is very exciting. With the upcoming hot-firing tests of the complete upper stage we will gain valuable insights into the technical heart of this new European launch vehicle.”