Spirit AeroSystems has officially opened a new R&D and test centre for high-temperature materials that can be used in hypersonic missiles and spacecraft.

The National Defense Prototype Center (NDPC) has been set up in partnership with Wichita State University’s National Institute for Aviation Research (NIAR) in the State to develop new capabilities for defense and space applications.

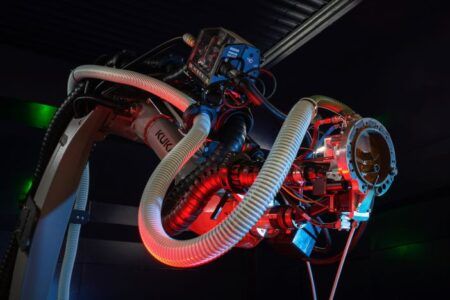

The 125,000 square feet facility includes manufacturing space and laboratories with processing and characterization capabilities, including high-temperature testing, furnaces for fabricating and processing materials, multi-method non-destructive inspection, robotic automated fiber placement technology and a large autoclave.

According to Spirit, the NDPC is the first of its kind with a focus on high-temperature materials that can withstand temperatures of 2,500-5,000°F for applications such as hypersonic missiles.

Duane Hawkins, Spirit AeroSystems executive vice president and president of defense and space said, “NIAR has been a tremendous partner in the development of the National Defense Prototype Center and enabling Wichita as a center for defense growth.

“The NDPC provides a secure space for high temperature materials testing, as well as development, prototyping and industrialization capabilities to support Spirit’s growth strategy targeting $1 billion of defense revenue by the mid-2020s.”

The research center comes soon after Kansas earned its designation as one of 11 Defense Manufacturing Communities by the USA’s Department of Defense (DoD).

“The National Defense Prototype Center will improve R&D efforts of advanced materials and place Wichita at the center of future defense and space programs,” said Senator Jerry Moran (R-Kan). “These programs, especially the advancement of hypersonic missiles, will rely on National Defense Prototype Center as the United States competes with foreign powers to defend our homeland.”

John Tomblin, Wichita State’s senior vice president for industry and defense programs and NIAR executive director said, “The more knowledge that can be generated and disseminated about high temperature materials, the more these materials can be used, optimized, and designed for specific objectives.

“This leads to reliable and safe products that enable the industry to go further, push faster, and break through current design limitations. Not only is this a first for the state of Kansas, but for the nation in terms of testing capacity at these temperatures.”