High-rate composite technologies for building next-generation aircraft have taken a step forward after the completion of a major cross-sector industrial R&D program.

The four-year, £39.6 million (US$51.3 million) ASCEND (Aerospace and Automotive Supply Chain Enabled Development) finished at the end of last year. The program focused on developing advanced, sustainable composite technologies for next-generation aircraft and other vehicles.

ASCEND, which was funded 50/50 by government and industry aimed to develop advanced materials and automation equipment required for lightweight structures in the sustainable air mobility, aerospace, and automotive industries.

GKN Aerospace worked with McLaren Automotive and other UK partners on high-rate production, Industry 4.0, and sustainable composite manufacturing technologies as part of the program.

The consortium was led from GKN Aerospace’s Global Technology Centre in Bristol and involved 130 people during 2023 and 2024.

ASCEND culminated in two flagship projects – GKN Aerospace’s bladed wingtip and McLaren’s rear floor component, both demonstrating the integration of aerospace precision with automotive production rates.

Significant progress was made in developing new methods, materials and processes, such as composite topology optimization with Rafinex, fast-cure prepreg technology systems from HEXCEL and Syensqo and joining mechanisms and cross sector bonding technologies with FAR and HIVE.

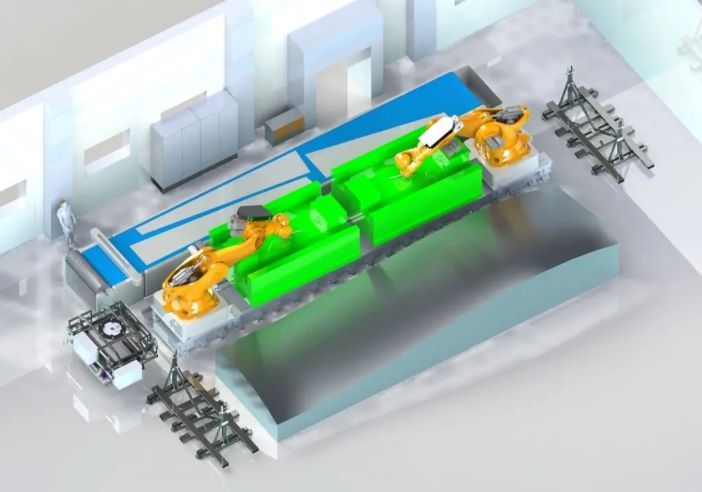

Automated systems were also developed from Loop Technology and GKN Aerospace’s RTM cell and Airborne’s Automated Ply Placement technology, showcasing the potential for high-rate, high-quality composite manufacturing.

John Pritchard, president of civil airframe at GKN Aerospace said, “We have deep knowledge and expertise in composite technology, and are proud to have led this consortium.

“Through ASCEND, we accelerated the development of next-generation lightweight, cost-effective advanced composite technologies – critical for the aerospace and automotive industries in their transition to more energy-efficient aircraft and vehicles. Successfully developing and demonstrating high-rate manufacturing capabilities across the UK supply chain has reinforced our position as an industry leader and underscored our commitment to sustainability.”

GKN Aerospace said that the ASCEND programme not only achieved its technological goals but also established a new paradigm for cross-sector collaboration, creating a robust supply chain and skilled workforce to support future innovations in composite manufacturing.

16 companies were involved in the ASCEND consortium: GKN Aerospace led the consortium alongside Assyst Bullmer, Airborne, Cygnet Texkimp, Des Composites, FAR-UK Ltd, Hexcel Composites, Hive Composites, LMAT, Loop Technology, McLaren Automotive, NCC (National Composites Centre), Rafinex, Sigmatex (UK), and Syensqo, with collaboration and investment support from Axillium Research.