After eight years of testing and development, USA-based Wright Electric’s goal is as clear and succinct to CEO Jeff Engler as the day he founded the company – to reduce the climate impact of the aerospace industry.

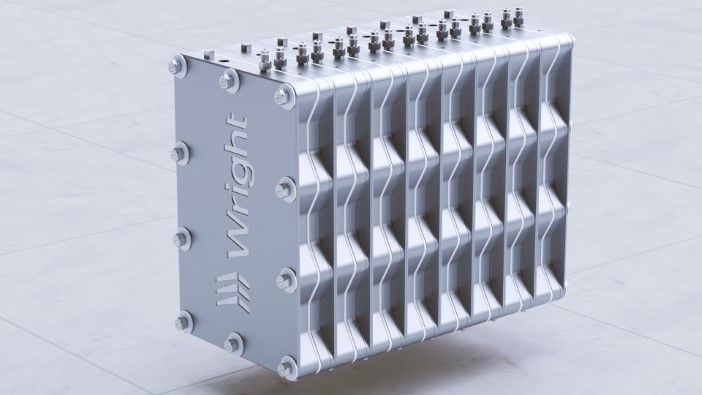

He and his company of around 20 engineers plan to do this by developing the world’s most powerful electric motor yet for aircraft, the 2.5MW WM2500, plus the associated inverter, power electronics, and battery.

For the last year work at Wright has been focused on how that electric powertrain could be fitted to a C-130 Hercules, including research with NASA and a detailed proposal published last October. In January engineers did an initial fit check of the WM2500 electric propulsion unit (EPU) at a US Air Force Base.

Wright wants to use a US Air Force C-130 for a flight test program, switching an engine for a hybrid-electric EPU, to prove the benefits of electrification.

According to research, a hybrid-electric converted C-130 could serve a range of 560 miles (900km) to 1,200 miles (1,900km) while giving fuel savings of between up to 44% compared to a conventional fossil fuel one.

Beyond the C-130, Wright’s roadmap calls for the EPU to be used to convert BAe 146 aircraft into a regional battery-electric aircraft to be called The Wright Spirit. Eventually, it aims to use the EPU to power an 186-seat clean-sheet airliner called the Wright 1, which will have an 800 mile (1,300km) range and enter service in 2032.

Test progress

Wright Electric is making good progress with its EPU. Last month it successfully ran its second generation 2.5MW motor and inverter linked together for the first time.

Strangely though, news about testing progress runs alongside announcements about tactical generators, lightweight batteries, and crop dusters in the company’s feed. It may appear that Wright Electric working in multiple industries, but there is a strategy behind it.

“Our business model combines the long-term vision of electrifying the aerospace industry with the short-term aim of finding ways to take our technologies to market before then,” says Engler. “We make motors, we make generators, and we are starting to develop batteries so we can fund our vision of large, electrified aircraft.”

Wright has been developing tactical generators for the US military since June 2023. The first flight of a 800 kW electric propulsion unit was in November 2023 in a hybrid-electric crop duster made by Spain’s Axter Aerospace. Last year it was awarded contracts to develop lightweight batteries by the US Air Force, ARPA-E, and the FAA.

Leveraging core competencies and technologies in adjacent areas makes business sense – but is there a risk the strategy distracts from the company’s main goal?

“We are an aerospace component developer first,” says Engler. “As we are developing our motors and batteries, we are always looking at the requirements from an aviation technical and standards perspective.

“But we are not going to be booking revenue from our aerospace-grade electric motor until it is certified, and that might be many years. With a long timeline, you will get shocks and surprises along the way. The only way around that is to focus on industry-leading technology and diversify in terms of programs and markets.

“For example with the tactical generators, we can leverage the overlap in technology – motors and inverters – and manufacturing readiness while also addressing the needs of our longer term aerospace mission.”

Despite this outlook, it is impossible to prepare for every eventuality, and with the US Government funding freeze much of the country’s industrial R&D base is at risk. “People tend to forget that when funding agencies such as NASA or the US Department of Energy are putting out funding dollars, it’s to train and equip the next generation of engineers. The suppliers and manufacturers who build leading technology that is going to help keep the USA and other parts of the world competitive for many years,” says Engler.

Testing milestones

Engler talks about business strategy and climate change with a fluency that reveals he is a problem solver on the macro scale. In contrast, Colin Tschida, Wright Electric’s chief technology officer seems more focused on micro-scale problems.

To Tschida, Wright’s most significant testing campaign so far was during the summer of 2024, when the team ran the first-generation motor to around 1.3MW in the lab. “That was a nice test, the motor was running very cool. We were essentially just limited by our test infrastructure,” he says.

“Not long after that, we validated our installation system in the lab. The testing showed it was PD [partial discharge] free at 43,000ft, exceeding our design target.”

Similarly, after the recent integrated run of the second-generation 2.5MW motor and inverter, the next test campaign will see the same system tested at simulated altitudes in the laboratory. “That’s the next big milestone for us,” says Tschida.

Ground-to-air

Partial discharge is an undesirable effect that can happen in high-voltage electrical systems which causes insulation to deteriorate and can lead to electrical fires and explosions. Higher voltages can help reduce the size of an electrical system and have other benefits, but require more insulation to prevent PD, adding bulk and weight, both of which are to be avoided in an aircraft’s design.

This voltage/insulation conundrum is typical of the challenge faced by engineers adapting ground-based electrical machines for use in aircraft, explains Tschida. An aviation environment’s different requirements can heavily influence both design and testing.

“Another interesting challenge the whole sector is grappling with is reliability,” says Tschida. “Industrial electrical systems do not have the same reliability requirements as aerospace ones. The standards are higher in aerospace – failure rates have to be lower. This means you have to be more careful with your component selection and cleverer with your design and testing.”

However, the answer to such challenges isn’t always to innovate. Sometimes, innovation can introduce more time, expense, and risk into a program. “We are careful about where we innovate. We don’t want to do it at every stage,” says Tschida.

“The development of an electric powertrain is completely different from a combustion engine, but there is a lot of heritage in electric motors that we can use – just not all of it.”

So far example the insulation system Wright Electric is using for its motor and inverter doesn’t differ too radically from those used in industrial systems and still uses typical resins and oil.

Electric Testing infrastructure

Wright Electric has two test cells, one of which is currently being built. There is a 2MW electric motor dyno, and the team is working on a test rig for an electric ducted fan to test the first and second-generation motors under fan load.

Tschida does not see the physical size of the motor as creating issues during testing: “Our 2MW motor will be similar in size to a PW100 series power turbine. That’s not enormous or too heavy.

“The main challenge for testing is that the power levels are high, which needs more infrastructure and safety devices. The setup becomes more sophisticated and expensive.

“We are also working to reduce the mass for a given power level. We want very high specific power, which creates its own set of challenges.”

A real advantage

Wright Electric has the ambitious goal of electrifying large aircraft because around 90% of aviation’s carbon footprint and 98% of its noise emissions are from aircraft in that category. However, Engler is keen to emphasize that his company is taking the same pathway to electrification that the market seems to be following – light sports aircraft to regional transport and then larger commercial passenger airliners.

Engler says, “In the long run our megawatt-class machines will be used in clean-sheet aircraft designs, but in the medium term, they will be used in regional hybridization applications.

“We don’t always have control over the timelines our products will get to market in because of regulatory and technical challenges, but in terms of the market the industry is coalescing around, we fit into that program.”

This timescale hasn’t stopped partnerships being made with charter jet firm Jetex and airline Easyjet in 2018 and 2020 respectively. These serve a higher purpose than greenwashing says Engler: “Understanding the needs of our customers is crucial to what we are doing.

“There are so many small decisions you have to make when developing new technology that an outside company could never really know all the details. But we are learning from airlines what their specific requirements are – in terms of power, takeoff, runway length. That helps us design the aircraft and the motor.

“There’s a real, tangible benefit to engaging with them early on, beyond the marketing advantage.”

Wright Electric’s goal of electrifying aviation may be straightforward to propose, but the route to achieving guilt-free flying is complex and challenging. Engler and Tschida though are keeping the end-goal firmly set in their sight. Engler says, “When we finished designing the motor, then when we assembled it, and then when we started basic testing, we were proud. You have to regularly take a moment to celebrate what you’ve achieved, even as you keep building and refining.”