Tucked away on the edge of aviation training provider CAE’s campus in Montreal, Canada is a laboratory containing a surprising side-project for a company best known for making flight simulators.

Visiting this laboratory is not a straightforward proposition. It requires a guide. The route takes in several office floors, through back-of-building fire exits and down bare-brick stairwells.

Upon arrival, the visitor is greeted by the sight of several Piper Archer light aircraft in various states of undress in two large rooms. There are fuselages and wings, test rigs, racks of lithium-ion batteries and a motor. There are test benches littered with avionics boxes and cables, and about a dozen engineers hard at work in an adjacent room with the blinds down.

The team here has been working on a project to convert the four-seater Piper Archer trainer to battery-electric propulsion since 2022. CAE runs several pilot academies around the world and has more Piper Archers, around 60, than other type of aircraft in its fleet. Most are based at its FBO in Phoenix, Arizona. By electrifying training aircraft, the company hopes to reduce its carbon emissions and reduce operating costs. It will also plans to sell the certified conversion kit to the wider market.

Remove and replace

The program is in the detailed design stage and last year passed the preliminary design review. The next big milestone is the delivery of the first flight test vehicle within the coming months.

“Once the aircraft is inside we will remove the combustion engine and everything else we don’t need. We are installing some of the batteries in the wings – their structure is being modified – and some behind the pilot by removing the rear seats,” says Mukund Patel, design lead for electric aircraft at CAE. “We will then install the new engine, a new propeller and cowling and integrate all the other components.”

The experimental aircraft uses a Safran Engineus motor. The team has a motor for testing purposes and recently attached this to a pressure drop rig to assess its flight performance. The team also performed testing at NRC (National Research Canada) facilities. Engine testing started in the Summer of 2023. “We simplified NRC’s setup to our needs, so we can test different iterations of the design quickly,” says Patel.

In the pressure drop rig, room air is compressed and fed across different parts of the motor. Pressure probes measure the pressure drop across the parts. “The data from the rig is closer to real life and allows us to see if our safety analysis is right,” Patel says.

Behind the pressure rig in the laboratory is an electrical systems mock-up being used for functional testing, consisting mainly of two racks of lithium-ion batteries supplied by Switzerland-based company H55. The racks are independent and represent the two halves of the battery pack, supplying current through the power distribution with the low voltage networks and DC/DC converter.

The same Engineus motor is used for both electrical and mechanical testing. “We are testing all our safety cases and that the electrical integration is up to par,” says Patel.

Access issues

Behind the electrical test bed is a semi-dismantled Archer fuselage being used to test the fit of parts and connections. Richard Alexander, aircraft integrator at CAE says, “We use it for testing concepts, to find out how new parts are going to fit and affect the aircraft. For example, battery packs are going where the rear seats were, and we are switching like-for-like in terms of weight. We also look at things like the seatbelts, the access, where to put buttons and displays, and what circuit breakers we need to replace.

“The biggest effort is probably the installation of the batteries, which is complex because they are distributed. There is an air distribution system that cools the batteries while they are charging. We also have to think about thermal runaway and containment.”

The CAE team has designed a removable leading edge and battery casings for the wing batteries so the cells can be replaced when they age. “We are taking the fuel tanks out of the wing and putting batteries in. There will be some additional structure to support those modules,” says Patel. “We use 3D printing to modify the physical mock-ups.”

Testing the energy system and the cockpit displays typify the challenge the team face around developing the conversion kit before the regulations for battery-electric aircraft are finalized.

Existing regulations are written for fuel that burns, not batteries that supply electricity. Aspects of the design such as which parameters concerning the battery and propulsion system must be displayed by the avionics is still being decided.

The regulatory approach for thermal runaway is also yet to be determined. When it is, it will have a massive factor on the detailed design for the battery’s integration into the aircraft.

“There isn’t a frozen framework for certification so any change can influence things,” Alexander says, “95% of the regulations are fixed, but that last 5% affects the other 95% and how you approach the overall design.”

Parts of the problem

According to Stella Filippatos, director of program management – electric aircraft, CAE, the fluid regulatory framework for electric propulsion is one of the biggest challenges the team faces.

She says, “It’s very difficult to meet regulatory requirements that haven’t been written yet.

“eVTOL has gained a lot of attention over the last few years, but these aircraft will be flying before eVTOLs. Regulators’ focus is beginning to be redirected onto Part 23, so they can become operational sooner.”

An associated challenge is around the supply chain for parts. “There is no volume production, so you are either waiting for parts or tailoring them to fit, in which case you are constrained by the geometry of the aircraft,” Filippatos says.

“We need the right parts to fly. The battery packs and motor we are using for testing are experimental and won’t be used in the final aircraft.”

Under the fuselage

The project isn’t all pioneering steps into the unknown. The Archer first flew in 1960. Piper as the OEM is providing support and know-how. Alexander says, “How the Archer operates and its safety record is well-established, which makes our job easier. It’s an ideal training aircraft, already certified and robust, we just have to electrify it.

“Almost everyone electrifying this class of aircraft is converting an existing airplane. The Pipistrel Velis is based on the Virus – a piston aircraft just like the Archer. Diamond’s is a conversion, Harbour Air’s Beaver and Aura Aero too. We are all following the same kind of pathway,” says Alexander.

The aim is to make a converted Archer as similar to the original as possible. A key consideration is devising ways to ensure that the pilot knows they are in an electric or piston version of the aircraft.

“We want to keep the handling as it is. The performance will change a bit but will be in the same ballpark as the existing airplane. We considered going hybrid, hydrogen combustion and fuel cells. But the battery solution is best for our mission,” says Alexander.

A broad curriculum

The final range of the converted aircraft is not being released yet, because the final weight may change. Regarding certification and entry-into-service dates, Filippatos empahsizes the broad nature of the program. “As an engineer, it’s tempting just to see this as a technical challenge, but to achieve entry into service a lot of work has to be done in the background.

“The program involves carrying out infrastructure changes at our FBOs so we can charge electric aircraft,” she says. “It also covers how to incorporate the aircraft into the curriculum and contract changes with our airline customers.”

It is unlikely that a converted Archer will offer sufficient range to deliver the whole curriculum, but this is no different from existing electric aircraft and is a restriction of battery technology. In addition, the handful of Velis already being used in the USA are not located in the same places as CAE flight schools, meaning there is no crossover for electrical charging infrastructure.

An FAA exemption for crediting pilot training in the Velis has also only just been granted and that is only to a basic level. “The Archer, can take pilots a longer way through their training program,” says Alexander.

CAE has never developed an aircraft before. The electric Archer project’s location on the fringe of its Montreal campus can be seen to reflect the company’s cautious approach to it. But the program also embodies CAE’s entrepreneurial spirit, which in the last 20 years has helped it grow from a simulator maker into a training provider. If the company can successfully expand into electric aviation remains to be seen, but the program has the backing of senior leaders in the business. “This will be a commercially available STC and conversion kit,” says Filippatos. “The architecture we are developing will be exportable to other aircraft.

“There’s a lot that needs to be figured out, even just for the experimental aircraft. Not a single day of this program is without challenges,” says Fillipatos.

“But the industry will learn a lot from operating these aircraft. That knowledge and know-how can be scaled up for use in larger aircraft.”

Simulator manufacturing

All CAE simulators are made at the one million square foot plant and head office in Montreal, Canada. The plant has 550 employees that work four shifts and is divided into four areas: fabrication, logistics and shipping. Production runs along a long straight line – fabrication is done on the left had side and assembly on the right.

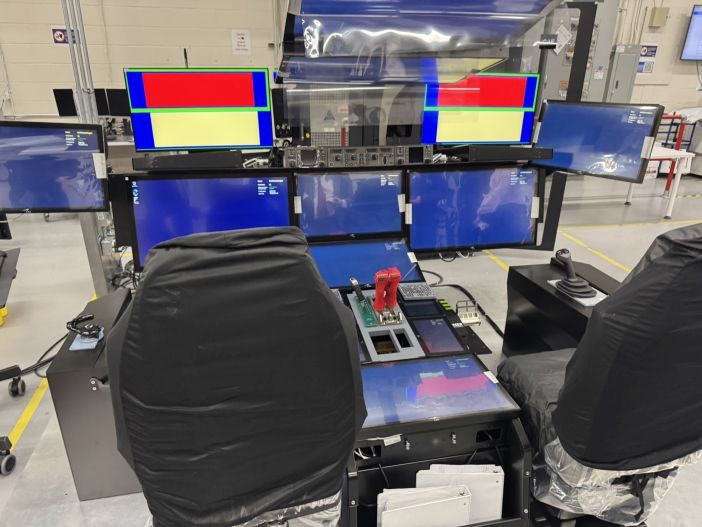

Around two full flight simulators are produced each week. Depending on the unit and customer, a simulator takes between 35 and 40 days to make. Each simulator spends about a week at a station before it arrives at testing and logistics to be shipped. Testing is done at the module level and the whole unit level to speed the process up.

About 10 years ago, the range of simulators was consolidated into one – the 7000RX series and the design modularized into five main parts to improve manufacturing efficiency. Although externally they look almost identical, inside the cockpits they are very different, and the software varies.

CAE’s factory in Montreal, Canada produces its range of flight simulators, from the full motion 7000RX series for flight training to the 400RX used for cockpit familiarizationOne of the most complex modules to assemble is for the flight controls. The flight module is also the final part of assembly and is “dropped” into the simulator. Testing of the electrical connections, data interfaces and software is then carried out. The site has 19 test stations and another 19 in a separate building.

The factory produces some 7000RX variants at high volume, A320s or 737s for example. It also makes limited prototype runs, as well as helicopter simulators such as the 3000 series in lesser amounts.

“Splitting high volume and prototype helped us increase production efficiency considerably,” says Steve Levesque, vice president of global hardware engineering and quality assurance.

Unusually, the manufacturing supply chain is vertically integrated to enable management to reduce dependency on suppliers and control over rate. The simulators are designed onsite, and the company even produces its own PCBs. “We had challenges in the past with lead time and quality,” says Levesque.