NASA aeronautics engineers are already testing concepts that could be candidates for the planned development of a series of greener, quieter, faster X-planes.

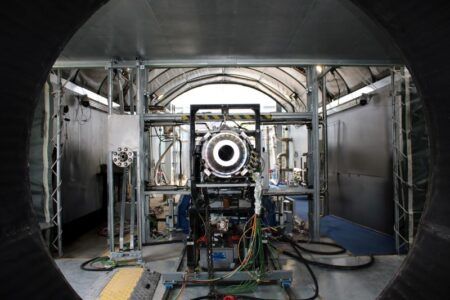

One of those is a blended wing body (BWB). A 6% scale model of a Boeing BWB is being tested for six weeks in the 14 x 22ft Subsonic Tunnel at NASA’s Langley Research Center in Hampton, Virginia.

A blended wing body doesn’t look like a conventional aircraft but is shaped more like a triangle where the wings are merged into the body and there is no tail.

This same model was previously in tested in wind tunnels at Langley in 2014, and at NASA’s Ames Research Center in California in 2015. That work was part of a NASA program to improve fuel efficiency, lower noise levels and reduce emissions.

For this test, the top has been painted in non-reflective matte black in preparation for laser sheets to sweep across the model. NASA and Boeing researchers will use those laser sheets, combined with smoke, in the technique known as particle imagery velocimetry, or PIV. This will map the airflow over the model.

“We didn’t get the opportunity to use PIV in the previous tests,” added Vicroy. “It helps us analyze the flow going into the engine inlets, which is one of the challenges with this design since the engines are on top of the fuselage, toward the rear.”

In most planes flying today the engines are out on the wings, in front, where there is nice clean airflow. Anything in front of an engine can disrupt the flow.

“Airflow makes a difference in how well the engine performs,” said Vicroy. “It’s a matter of how much distortion the engine is seeing. So if you want the engines to perform well you want to have the distortion at a minimum.”

Researchers say putting engines on the top of the plane helps shield noise, especially from people on the ground, and contributes toward developing greener, quieter aircraft.

The other benefit to NASA from this test is more to do with the tunnel itself. Repairs and an upgrade were recently competed on the 14x22ft tunnel, so having the same model return can verify how well it’s working. Furthermore, having the same model tested in a totally different facility, such as the one in California, also helps add to engineers’ knowledge base.

“In wind tunnel testing we have to account for how the model is installed, the size and proximity of the tunnel walls in the test section, and other factors,” said Vicroy. “Testing the same model in two very different tunnels gives us data to improve our test correction methods, some of which were developed in the 1940s.”

With the exception of Boeing proprietary technology, NASA knowledge gained from this collaborative research will be documented and publicly available to benefit the aviation industry.

September 9, 2016