Hardware-in-the-loop systems have helped to reduce flight testing of Saab’s latest fighter jet, writes National Instruments in this case study.

The Gripen Fighter System is a key product for Saab’s Aeronautics Division in Linköping, Sweden. According to Saab, the Gripen is a smart multirole fighter system that balances operational performance, advanced technology, industrial partnerships, and cost efficiency.

Saab is developing the Gripen E as the latest addition to the fighter system with the latest avionics technology, improved radar systems, and advanced communication features.

The Gripen E successfully completed its maiden flight over southern Sweden in June 2017 and enigneers have used hardware-in-the-loop to test the aircraft’s systems

Hardware-in-the-loop

To help develop the fighters, Saab is using simulators and rigs for its hardware-in-the-loop (HIL) systems, to test the various Gripen line-replaceable units (LRUs). These LRUs include flight control systems, tactical systems, sensors, and other avionics equipment.

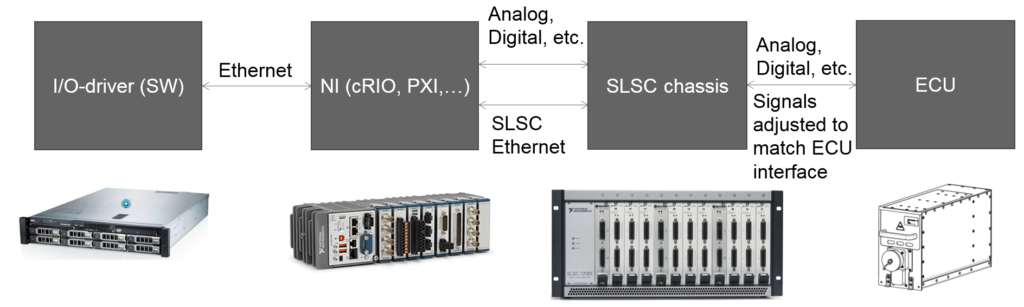

In the most complex tests, up to 40 interconnected LRUs must be tested together. Engineers began by looking for a suitable commercial off-the-shelf (COTS) product to use as an I/O system in the HIL systems. They selected the National Instruments (NI) PXI and CompactRIO platforms because of their modularity and expansion capabilities, advantageous features when there are many different signal types. The HIL system was built using several CompactRIO systems and NI’s LabVIEW software to control it.

The HIL system has enabled the engineers to check that the LRUs work as expected by simulating the real-world environment. The company has run many LRU tests without putting a fighter in the sky, which can be costly and potentially dangerous. In Saab’s HIL system, we use the CompactRIO to produce simulated signals for the LRU and receive the output from the unit.

Switching, loads, and signal conditioning

To make the system specific to the application Saab engineers needed custom signal conditioning and functionality between the CompactRIO and the LRU. They did not immediately find a COTS solution for customised signal conditioning along with switching and applying loads, so started an internal development project to integrate the NI equipment with the simulators.

During this project they partnered with NI to use the company’s Switch Load and Signal Conditioning (SLSC) system. The SLSC solution extends PXI and CompactRIO measurement hardware with high-power relays for signal switching, power loads, and additional in-line signal conditioning capability. The system consists of a chassis with built-in active cooling capable of hosting 12 modules that can be used in applications such as our HIL testing.

The SLSC system was similar to one being developed internally and because NI was already a preferred supplier for Saab easier to obtain. NI defined the ecosystem or “constraints” for the switches, loads, and signal conditioning targeted at HIL applications with the NI platform, reducing man hours spent on the project and costs.

Modules for the SLSC can be obtained from a variety of third-parties or created in house. Saab creates its own modules by working with local developer Syncore Technologies.

The intellectual property from some of our existing designs can be used within the SLSC MDK and design guidelines. The company also worked with NI to outline its requirements and partnered with aerospace firms Bloomy Controls and SET for modules.

Benefits

Saab uses the SLSC system to focus on developing custom circuitry following the constraints defined by NI in the SLSC standard, saving time and development resources.

Having a COTS product also means the company can contain development and maintenance costs. Using the SLSC system also allows engineers to focus their attention on building HIL test systems and rigs, not developing advanced hardware.

The company is integrating SLSC into a simulator and plans to use CompactRIO and SLSC in a number of new simulators in the near future, to continue testing innovative functionality for the Gripen fighters in a short timeframe and lowering the cost of testing.