A group of engineers at the US Air Force Research Laboratory has helped NASA determine the effects of unintended electrical arcing on astronaut spacesuits during extravehicular maintenance using low-pressure chambers and high speed cameras.

NASA researchers needed to know how an electrical arc behaves in a vacuum, a concept that had not been explored fully before.

“What was not understood were the ramifications of an arc in space,” said Brett Jordan, electrical and electronic materials evaluation team lead at the Air Force Research Laboratory (AFRL). “What are the mass and velocity of the particles produced by the arcing, and what would be the effects of those metal particles flying off the arc in that environment?”

To answer this question, AFRL engineers began by determining how to build fixtures for a low-pressure test and performing proof-of-concept testing to determine the best method to reliably create an arc in the planned lab setting. This initial series of tests helped the researchers understand the materials, positioning and current needed to successfully generate the arc, as well as the proper test setup to use for an Earth-orbit vacuum environment.

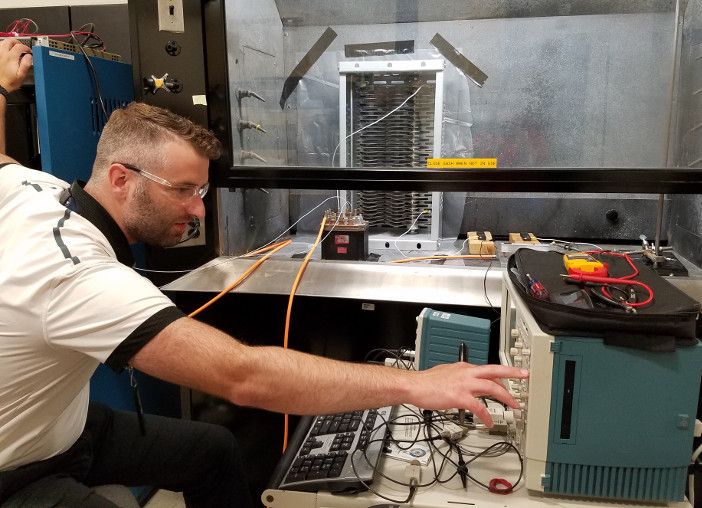

With this initial data in hand, the team acquired a low-pressure chamber and secured a laboratory for conducting the tests. “It really was a team effort,” said Corey Boltz, electrical engineer and project lead. “We received assistance from many different teams throughout AFRL to make this happen.”

After another round of experimental tests and setup, the team was ready to begin the final round of testing and data collection. With the assistance of NASA engineers, the AFRL team performed a series of 35 tests in the low-pressure chamber.

Each test run was a careful exercise in control and precision. For each individual test, the team followed a rigorous process that involved precise placement of the test fixture, calibration of multiple high-speed data capture cameras and pumping the chamber down to extreme low-pressure atmospheric conditions.

The team completed the tests quickly, despite the complex setup required between each test run. From start to finish, the low-pressure test runs were completed in nine days. Jordan says this was possible because the AFRL test chamber offered capabilities that were not immediately available to the NASA team.

The chamber’s design meant its pressure could be lowered to the necessary test conditions in about half the time it takes a typical chamber to achieve the same conditions. As a result, more test runs could be completed in a shorter period of time.

“For us, it was all part of our rapid-response mission, and the customer appreciated that quick turnaround,” Boltz said.

The data gathered from the testing provided important information for NASA to use for structuring their own set of tests.

“This data-rich testing enabled the optimization of tests being performed at three other facilities, which are adding various other factors related to the extra vehicular activity scenario,” said Amri Hernandez-Pellerano, NASA technical lead. “The AFRL pathfinder tests enabled us to properly plan resources in this study.”

Jordan added that since these tests were the first space vacuum work the group had performed, the testing event benefited AFRL as well by expanding the base of knowledge for electrical arcing in low-pressure environments. He said the data and processes established will be useful for the project researchers and other AFRL teams as they tackle future endeavors.

“As the systems support rapid reaction team, that’s what we do,” said Jordan. “We’re proud of our mission. We take it seriously, we enjoy it, and when we need to come up with good answers quickly, we make it happen quickly.”