Words by Jack Roper

A multimillion European research program is developing the tools that will shape the next generation of flexible and efficient aircraft wings.

Engineers are developing less heavy, slender carbon-composite wings for the next generation of commercial aircraft to improve the fuel-efficiency of conventional tube-and-wing airliners. But low vibrational frequencies make these lighter wings more flutter-prone than stiffer wings. Flutter thus imposes optimization constraints on the aerospace industry. The removal of these constraints is what the US$7.2 million (€6.6 million) European FLEXOP (flutter free FLight Envelope eXpansion for ecOnomical Performance Improvement) set out to resolve.

“In 2014 we saw advances in the USA and realized Europe had to start mastering flutter-suppression,” says FLEXOP’s project leader, Dr Bálint Vanek, of the Hungarian Computer Science and Control Institute, SZTAKI. “We wanted to build a demonstrator, make and test flexible materials, then link our technologies to next-generation aircraft in a scale-up study.”

FLEXOP was initially focused on active flutter-control but was soon extended to encompass passive load alleviation by aeroelastic tailoring. Gusts make wings bend and exert loads at the wing-root, but aeroelastic tailoring can mitigate gust-loads by optimizing the anisotropic qualities of carbon-fiber materials.

“Carbon-fiber is unidirectional, like the grain in wood,’ says German Research Centre DLR’s head of load analysis and aeroelastic design, Dr Wolf-Reiner Krüger. “Its behavior depends on whether it is loaded along the fibers or perpendicular to them. We simulated the optimal thickness and direction of carbon-fiber layers for passive load alleviation.” In a gust, the tailored wing not only bends but twists, decreasing the local angle of attack on the wing and reducing loads.

Three wing designs were manufactured by Austrian project partner, FACC: a stiff, reference wing, a tailored wing and a third wing, with active flutter-control. “In the region of flutter, unsteady aerodynamics occur naturally around the wing,” explains flight-test manager Julius Bartasevicius from the Technical University of Munich (TUM), a FLEXOP project partner. “But moving ailerons up and down can create additional unsteady aerodynamics to counteract that. It’s about control systems and modelling. You must either know at what speed to actuate the ailerons, or measure axle vibrations and channel that into a flight-control computer which actuates flutter suppression.”

One of FLEXOP’s aims was to demonstrate to certification agencies that active control surfaces could ensure safe flight above flutter-speed.

Model & vibration tests

DLR, TUM and industrial partner Airbus used simulation to model flutter’s affect on wings. “We drew on existing literature and military flutter-damping flight-tests to build a mathematical aircraft model,” says Vanek. “We could predict flutter and show how our system could implement control laws to achieve higher velocity.

“In simulations, we could push flutter-speed upwards by 20%. We designed our first control system iteration and simulated it with a full-aircraft model. We ran a hardware-in-the-loop simulation with the actual flight control computer to test our algorithms and see if we could execute all commands in real-time.”

Considerable work went into optimizing the configuration of special sensors built into the wings to measure their behavior in flight. “We were initially unsure whether we needed 0.1° or 10° actuator commands,” Vanek says. “Sizing actuators differently creates different mass penalties, so we had to understand the limits and trade-offs.”

Conventional data acquisition systems were too heavy, so a Raspberry Pi computer was used to process the data from lightweight internal sensing. “We installed fiber-Bragg sensors, which gave us 300 measurements per wing-pair at 200Hz grade,” he says. “We used accelerometers and gyroscopes to measure normal acceleration, bending and torsional angular rate and recreate wing behavior.”

Once manufactured, the wings underwent ground vibration tests (GVT) at DLR’s Göttingen Aeroelasticity Research Institute. “We validated our models and identified the global dynamic properties of assembled structures,” says Krüger. “We tested at four excitation levels to ascertain eigenfrequencies and mode shapes.’ Around 100 triaxial acceleration sensors measured how wings reacted to electrodynamic shaker inputs, enabling reciprocal damping estimates to be calculated. “While the aircraft was vibrated, data-acquisition techniques could also be tested,” he adds. Data from integral wing sensors differed less than 2% from DLR’s external, state-of-the-art sensor results, confirming an ability to measure wings in flight with laboratory-like precision,” he adds.

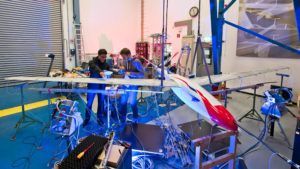

FLEXOP’s 65kg, 7m-wingspan unmanned demonstrator aircraft was shaped by both experimental and industrial requirements. “US flutter-mitigation flight-tests use blended wing-body demonstrators,” Vanek explains. “But we opted for a conventional, wing-fuselage aircraft which was more industrially relevant.”

Demonstrating control of flutter meant making wings which were prone to it, going against established design aerodynamic and structural design thinking. Vanek says, “As wingspan decreases, oscillation frequency increases and we can’t show anything interesting. We went with the highest wingspan we could handle to get a flutter-speed below 60m/sec.”

This demanded a frequency below 8Hz, achieved using a 7m wingspan with additional masses attached to tune flutter-speed downwards.

Beyond Visual Line of Sight

last November

Test-flights at Oberpfaffenhofen Airport near Munich were first scheduled for 2018. But German Civil Aviation Authority unmanned aerial vehicle (UAV) regulations are not well-defined and stringent safety requirements made for a lengthy development process. “There are offices around the airfield and a public road at one end of the runway,’ says Vanek. “A 65kg aircraft is not a toy. We had to design a flight termination system and demonstrate redundancy, so that if one component or system fails, the aircraft still flies. We simulated the flight beforehand, preparing the crew to conduct it sequentially and formulate contingency plans.’

Critically, current German rules preclude flying UAVs beyond visible line-of-sight. “Staying within visual range means a maximum distance from the pilot of 1km in either direction,” says test-flight manager Bartasevicius.

“That defined the 2km airspace box we had available. Ten seconds of flying at 60m/sec flutter-speed takes 600m and 15 seconds is already half your airspace. Obviously, you must first reach that speed, then turn around in a confined area.” Rapid acceleration to flutter-speed necessitated a jet engine and an airbrake enabled the demonstrator to quickly slow back down within its 2km visibility-envelope.

“The ground control-station was a Mercedes Sprinter van with integrated antennas, laptops and work-places for the crew. The pilot has a standard radio-control transmitter. The back-up pilot is always ready to assume control if something happens. The operator guides the aircraft on a map, telling it to bank, turn or change altitude, while the engineer monitors engine parameters and aircraft health. It was a tough test-campaign. 70 people had worked on the aircraft for four years, so the moment it actually took off, flies and lands – it was a great feeling,” Bartasevicius says.

On August 1 2019, FLEXOP’s demonstrator finally attained Bavarian skies.

“After two flights, we installed the fiber Bragg system and started collecting data,” says Vanek. “We could test changes in wing-shape during bank turns, high g-loading and nose-down, nose-up maneuvers.” This enabled Vanek’s team to validate their models, which were closely matched by flight-test data. The aeroelastically-tailored wing did indeed behave as predicted, providing better load alleviation than the reference wing. “It was nice to see the expected trends,’ says Vanek. “Now we can refine our tools and methodology with some confidence that our models match the aircraft’s behavior. “We showed that what we claim in simulation actually happens in flight.’

Next steps

The delayed timetable left no time to test the third wing, with active flutter-control. But that will now fly in FLiPASED, a recently-announced follow-on project. Meanwhile, FLEXOP’s industrial relevance is being explored in an Airbus scale-up study, led by TU Delft’s Dr Roeland De Breuker, who spent a sabbatical at Airbus during the project.

“We applied tools and methods validated in our test-flight to a long-range passenger aircraft,’ says De Breuker. “We used a derivative aircraft based on the Airbus XRF1 research model. Our objective was 7% fuel reduction or a 20% payload increase – we achieved 8% fuel-reduction and 25% payload increase.

“We believe we can implement systems on passenger aircraft that could fly in ten years.”

FLEXOP dealt separately with aeroelastic tailoring and flutter-control, but Airbus is interested in the benefits achievable from combining both technologies in one wing. “There’s a trade off, because you need flexibility for aeroelastic tailoring but you need stiffness for active control surfaces to work effectively,” says De Breuker. “The question is: where’s the sweet spot between them?” Finding the trade off will be FLiPASED’s focus.

“Now we can use existing know-how and infrastructure to begin test flights as soon as possible,” says Vanek. “For Airbus and Boeing, this flutter problem comes up continually. New aircraft don’t happen every year, but it’s on their next-generation horizon. We’ve collaborated with EASA and FAA to ensure this isn’t just an academic example but really tied to certification. We’ve built sophisticated aircraft design tools from scratch and got some nice results. But aero-servo-elastic interactions between aerodynamics, structures and control systems could create even greater efficiencies.”

This article was originally published in the March 2020 issue of Aerospace Testing International magazine. View in its original format here. Subscribe to the quarterly magazine for free here and to the weekly newsletter here.