Words by Paul Willis

When a six-seater Piper took to the skies at Cranfield Airport in southern England during June it made history as the first ever electric-powered flight of a commercial aircraft in the UK.

The flight was significant for another reason. Unlike most prototype electric-powered aircraft recently developed, it was not fitted with lithium batteries but was powered by a hydrogen fuel cell engine developed by the California-based startup ZeroAvia.

ZeroAvia isn’t the first to experiment with hydrogen power as an emissions-free alternative to fossil fuels. In 2016 a research project led by German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) called Hy4 saw a four-seater hydrogen fuel cell-powered passenger aircraft take to the skies above Stuttgart for a short demonstration flight of 15 minutes. According to the HY4 project, which involved partners Hydrogenics, Pipistrel, H2FLY, the University of Ulm and Stuttgart Airport, the HY4 aircraft can achieve a range of up to 1500km depending on the speed, altitude and load during flight.

Then, during May last year the Massachusetts-based start-up Alaka’i Technologies revealed a full-scale model of a multi-rotor hydrogen-powered craft designed in partnership with car maker BMW.

Energy intensity

The advantages of using hydrogen as an aviation fuel are well-known. The chemical’s high energy potential – per unit of weight pure hydrogen is actually three times more energy intensive than jet fuel – meant it was first developed as rocket fuel for the US space program during the late 1950s.

Yet despite its long history as a rocket propellant, hydrogen has been overlooked by the world of commercial flight. There are two main reasons for this, says ZeroAvia CEO and founder Val Miftakhov. The first is that hydrogen’s low density means that compared to conventional jet fuel it requires a great deal more storage space. The other reason is that “when you burn hydrogen there’s not a huge advantage relative to jet fuel,” says Miftakhov.

“The turbines are actually no more efficient with hydrogen, in fact they could be less efficient,” he says. “What’s more, you still have all the disadvantages of burning things – you’re going to create high temperatures which means a lot of stress on your parts, and high maintenance costs.”

However, there is growing pressure on the aviation industry to find sustainable alternatives to fossil fuels. Miftakhov says this pressure has more to do with the long-term outlook than aviation’s current CO2 output, which is estimated to represent around 2% of global emissions, according to figures from the Air Transport Action Group.

“Aviation is not a huge contributor to CO2 emissions worldwide today,” says Miftakhov. “But it is the fastest growing segment of transport and while all the other transportation modes are de-carbonizing, aviation doesn’t really have scalable solutions to move the needle on reducing CO2 emissions.”

Battery deficiency

The scalability of hydrogen as an aviation fuel is key. While a number of tech startups and leading OEMs are developing battery-powered air taxi concepts, also known as eVTOLs (electric vertical takeoff and landing) aircraft, there is growing recognition that battery power can’t make the leap to larger craft. “Lithium batteries have a fundamental technical barrier – they have a low energy density,” says Alex Ivanenko, co-founder and CEO of HyPoint, a California-based company developing a hydrogen fuel cell engine for aircraft.

Hydrogen’s relatively high energy density and recent advances in fuel cell systems’ technology mean it can now being looked at as a viable future alternative to jet fuel. “Fuel cell technology has become efficient enough and inexpensive enough to make it realistic to use hydrogen electric power,” says Miftakhov.

Hydrogen does pose its own set of problems though, says Ivo Boscarol, the founder and general manager

of electric aircraft-maker Pipistrel.

“There are a lot of challenges,” says Boscarol. “From the safe storage of larger quantities of hydrogen, to fuel cell contamination and obtaining a good enough efficiency. But these are all solvable and I believe that the near future will bring very exciting solutions, which will also be certifiable for the commercial operation of aircraft.”

ZeroAvia’s faith in hydrogen is shared by the UK Government, who last September awarded the company a £2.7 million (US$3.5 million) grant through its Aerospace Technology Institute to develop a hydrogen fuel cell powertrain for use in commercial aviation. Since then Miftakhov has shifted the company’s base to Cranfield.

“We are currently preparing the aircraft for the next phase of flight testing where we will be testing the hydrogen fuel cell integration and longer distance flights,” says Miftakhov.

The goal for the end of 2020 is “to demonstrate up to 300 miles of zero emission flights in a commercial-grade six-seater aircraft,” he says. The aim is to successfully demonstrate their technology on a 10- to 20-seat regional jet within the next three years.

Storage complexity

For this first phase of development ZeroAvia is developing a fuel cell system that runs on compressed hydrogen gas rather than the liquid hydrogen that is used in rocket propulsion.

The reasons for this are twofold, says Miftakhov. The first is that liquid hydrogen is expensive because the gas has to be super cooled and maintained in that state. Secondly, the liquefied version requires more complex systems than the gaseous state for both storage on the ground and on the aircraft. According to Miftakhov, this extra complexity is likely to slow down certification “You have more modes of failure you have to mitigate against,” he says.

When it comes to developing its powertrain for larger commercial aircraft, the company intends to switch to liquid hydrogen. The pressure vessels required to store gaseous hydrogen are bulky, says Miftakhov, meaning that the fuel containment system is much heavier relative to the amount of fuel it contains.

On ZeroAvia’s modified six-seater Piper, for example, fuel makes up just 11% of the total weight of the fuel system, says Miftakhov. While this ratio can work for smaller planes, the fuel requirements of larger jets would result in a fuel containment system too heavy to get off the ground.

In liquid hydrogen fuel systems by contrast, fuel makes up to 80% of the total weight of the fuel system. Since ZeroAvia doesn’t anticipate transferring their technology to bigger size jets until at least six years from now, the hope is that by then “the cost of liquid hydrogen will have come down sufficiently and it will become economical relative to jet fuel.”

Temperature challenges

Like ZeroAvia, HyPoint are also pinning their hopes on hydrogen as the future fuel of aviation. HyPoint’s fuel cell system contains a high temperature polymeric electrolyte membrane (HTPEM). This membrane allows the system to function at much higher temperatures than conventional fuel cell engines and helps to reduce its size, says Sergey Shubenkov, HyPoint’s co-founder and head of R&D.

“The real problem for fuel cell systems is that while they need to operate at relatively low temperatures, they also produce a lot of heat,” says Shubenkov. “This means they need to have big, complex cooling systems that are much bigger than the fuel cell system itself.”

Since HyPoint’s system can operate at twice the temperature of similar conventional fuel cell systems “this means we can reject the heat much more easily,” says Shubenkov.

The company’s other innovation is to use air-cooling rather than liquid-cooling. “The combination of air cooling, high temperature and specialist design has allowed us to develop a system that is many times lighter than those of our competitors,” adds Shubenkov.

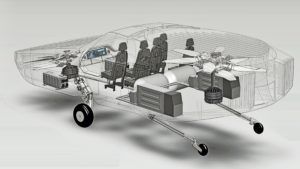

HyPoint’s technology has attracted the interest of the Israel-based company Urban Aeronautics, which has agreed a deal with the company to develop a hydrogen engine for its proposed CityHawk. air taxi. The vehicle is currently powered by jet fuel, but the company wants to switch to a fuel cell system powered by hydrogen gas.

Replacing the CityHawk’s combustion engine with a fuel cell engine shouldn’t bring up any insurmountable technical barrier, says Urban Aeronautics CEO Rafi Yoeli: “The fuel cell engine and the combustion engine are the same in that fuel and oxygen go in, and energy goes out. Except that for fuel cells it’s electrical energy. This means that instead of mechanical power transmission to the rotors we need electric motors on the rotors.

“There would also be design changes required to accommodate the larger tanks needed to store the hydrogen gas. It’s a major modification on the aircraft but not in terms of the power required.”

In the end Urban Aeronautics think the switch will be worth the effort. “Fuel cells, unlike batteries haven’t reached any plateau in terms of their growth potential of power to weight,” says Yoeli. “And because hydrogen is 100% sustainable we think this is the way to go.”