The construction and equipment installation phases for three A321XLR flight-test aircraft are nearing completion at Airbus’ final assembly line in Hamburg, Germany.

The first of these, the MSN11000, will soon be handed over to the flight-test team. Concurrently, ground-based testing campaigns are underway at various Airbus sites in preparation for incoming flight-test and certification programmes.

One of these is the Virtual First Flight (VFF) campaign to clear the aircraft’s new systems, flight control laws and the flight crew for commencing flight tests. This part of the A321XLR’s development focuses around a dedicated development simulator and a co-located avionics testing laboratory in Toulouse, France.

Virtual flight-test campaign

In contrast to a full-flight simulator which moves on hydraulic jacks, the VFF is fixed to the floor. Featuring real pilot controls and displays, there are also dedicated workstations behind it which feature displays and user interfaces as used by flight test engineers (FTEs). These will be used to monitor the flight and adjust testing parameters in the real aircraft.

Adjacent to the development simulator’s entrance is a virtual flight testing laboratory room with numerous racks containing real avionics modules. These are identical to those being installed in the avionics bays of the three A321XLR flight-test aircraft. These modules can be connected directly to the simulator, virtually flown and evaluated by the Airbus test pilots while being monitored by the FTEs.

Linking the avionics in the lab directly to the simulator enables the engineering test pilots to validate the A321XLR’s modified flight control system laws and in specific conditions, such as during flare or high-speed flight. They are also able to evaluate and fine tune the aircraft’s handling od external disturbances typically encountered during normal flight.

Vincent Claudel, Team Leader Lab & Flight Tests, said: “The virtual flight test campaign which started in March will culminate with a Virtual First Flight ‘rehearsal’ or dry-run. For this exercise all the flight crew, comprising the test pilots, the test-flight engineer and the flight-test engineers, who are already assigned for the first flight, will be seated in the simulator where they will run through all the phases which they will subsequently perform in the real aircraft.”

Vincent added: “The phases which they will rehearse during the VFF dry-run include, for example, the electrical and engine power-on, taxiing out, take-off, climb, the flight domain opening, all the way to landing, taxiing back, and powering down again. In fact, they will do everything they will do in the real flight, and in exactly the same order.”

Flight control system functional integration testing

In order to validate the flight control computers so they may be subsequently integrated with the main simulator, the avionics modules are first tested and fine-tuned by engineering specialists in a nearby laboratory using ‘Controller and Guidance Integration Benches’ (CGIBs).

“Before the avionics modules can be connected to the simulator, they undergo integration operational testing to validate them at system level to ensure the good behaviour of the aircraft’s flight control laws which they govern,” notes Vincent.

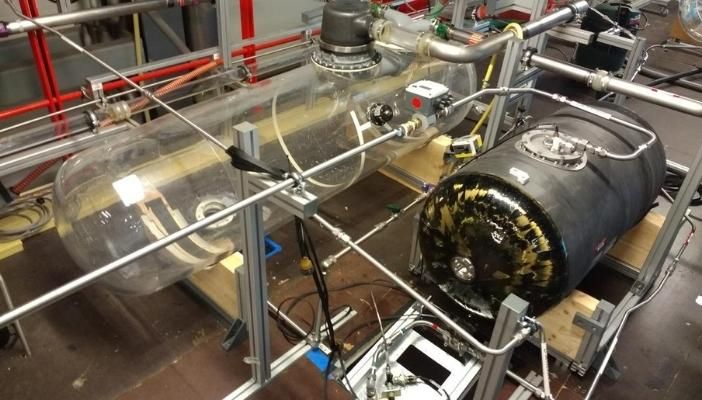

Partial ‘iron-bird’ ground test rig for the vertical-tail plane’s new eRudder

The simulator can also be directly connected to and control physical aircraft hardware such as hydraulically-actuated control surfaces on a test-rig. On a new programme, such as the A350, this test rig was called an iron bird. However, since the A321XLR is a development of the A321neo, it was sufficient to provide a physical test rig representing just the tail section, in this instance the the vertical tail-plane (VTP). This is to facilitate ground testing of a new ‘eRudder’, which is being introduced across the A320 family.

Ground-based systems integration and testing

“The majority of the tests – such as for the flight control laws and autopilot – to prepare the [A321] XLR for its first flight are being performed by the engineers and flight test crews in Toulouse, using the simulator plus the avionics benches. However, other test campaigns have been underway for more than a year already at the various Airbus sites to clear additional systems which are related to specific ATA Chapters,” notes Vincent.

To this end, the transnational development teams in Toulouse in France, Hamburg and Bremen in Germany and in Filton in the UK, have collaborated in the XLR’s test-means campaign and systems integration activities.

Vincent continued: “In Filton, UK, we have two big benches for what we call ‘Landing Gear Zero’ for validating the XLR’s new uprated landing gear, wheels and brakes (ATA Chapter 32). Also in Filton is a ‘fuel integration bench’ to test the new fuel and inerting system (ATA Chapter 28) for the -XLR, and in particular to validate new modifications for the aircraft’s new Rear-Centre-Tank (RCT).”

“Meanwhile in Bremen, Germany, we have the high-lift system bench to validate the new inboard single-slotted flap configuration which is specific to -XLR. Then in Hamburg, we have air conditioning benches (ATA Chapter 21), as well as a ‘water & waste’ bench (ATA Chapter 38). Also in Hamburg we have a multi-climatic chamber to optimise the comfort in the cabin and cockpit during the long flights at high cruise altitudes.”

“Even after the first flight is accomplished we will continue to perform our ground lab test means at all these sites as well as simulator tests in Toulouse, in parallel to support the year-long flight-test campaign, the Certification programme and beyond,” says Vincent.

This article was originally published by Airbus here.