The test and development of spacecraft is difficult for one major reason – you can’t access a true representation of the environment of space on Earth.

It’s a challenge that engineers over the years have dealt with through various means, such as thermal vacuum chambers, machines that rotate to recreate microgravity and the training of astronauts at the bottom of swimming pools.

However advanced digital tools offer engineers the opportunity to faithfully recreate the conditions of space virtually, speeding up and reducing the cost of development times. Meanwhile, new approaches to design and analysis are enabling engineers to deal effectively with the increasing complexity of spacecraft.

Model-Based Design

Ossi Saarela, space segment manager at software firm Mathworks works with the space industry to help them “achieve success through the use of modern engineering tools” and supplies its Matlab and Simulink products to a range of companies across the industry.

Saarela says, “There are a lot of things in space you can’t test because you don’t have a zero g environment. With increasing computing power, engineers have been able to improve simulations and reduce the amount of expensive testing time.

“It would be very difficult to find a company that is not using Matlab or Simulink for things like numerical analysis.

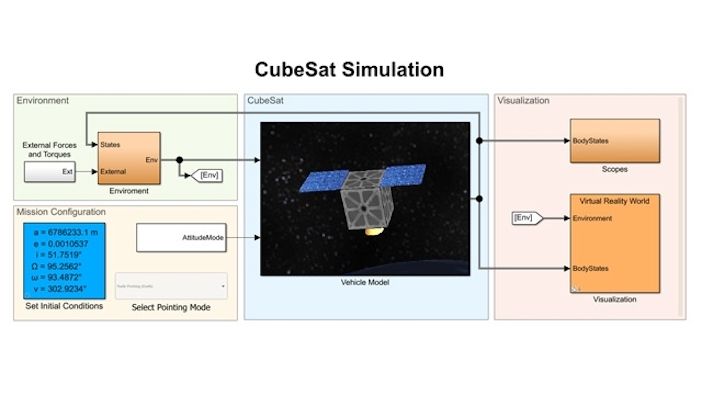

For example, engineers on NASA’s Orion-manned mission are using Simulink to develop its guidance navigation and control systems. They are employing an approach to development using the software that is becoming increasingly popular in space companies, called Model-Based Design.

Model-based design is a visual approach to designing systems and the embedded software for them. By creating a model of a system early-on in the design process, engineers can test and make changes earlier in a project.

Model-based design also presents the opportunity to better preserve engineering data by leaving an artefact of the design behind after a development program has concluded. This is important because spacecraft and systems are becoming increasingly complex.

“Systems are getting more complex as mission requirements become complex. If you wait until the end of a program to develop or integrate systems, you will often get problems.”

“Early in the prototyping phase you mature the model and add fidelity. Once you need to deploy software or HDL [Hardware Description Language] code for FPGAs [Field-programmable gate arrays] you generate it from the model. It’s not just a model, it becomes the software.

“On the hardware side, as actual components become available you integrate them with model for hardware-in-the-loop testing.”

Tools for the new space race

Competition between private space companies has created a challenging environment for engineers, who have to rapidly prototype while maintaining the level of rigor needed for high level integrity operations.

In this environment, testing remains the lengthiest and most expensive phase of development. The amount of time and cost spent testing can be reduced by using Model-Based Design to find issue before testing, say Mathworks.

Test engineers should become involved in development around the time real-time testing begins, when hardware enters the process, Sareela believes.

“To gain more efficiency from Model-Based Design, test engineers should be engaged when requirement-based test cases are being developed from the model. These cases should then carry all the way through development,” he says.

The need to increase the efficiency of development in areas such as systems integration and software development for spacecraft is only likely to grow in the future. A model-based approach can help here also, Sareela believes, by enabling engineers to work in a more multi-disciplinary way. “Spacecraft have changed in the last decade. Instead of hardware-centric, they are now software-centric machines,” he says. “If there is a need for any area of expertise in the space industry right now, it is for software testing.

“I see a growing need for engineers to be able to step out of their disciplines and work in other areas. Model-Based Design can help enable this, it removes silos by having a single model everybody is working on.”