15 years or so, the US Air Force has flown thousands of combat hours in permissive environments, against enemies offering little or no threat to fixed-wing air power. Including regular visits to the air refueling tanker, missions require fighters – typically F-16s or F-15Es – to loiter as they await the call to deliver precision effect.

When a commander requires ordnance on a target at range and quickly, nothing delivers capability more effectively than a fast jet, but targets vary and where persistent air power is required over an unpredictable battlefield, fast jets may not be the most economical or suitable option. Remotely piloted air systems (RPAS) offer persistence and precision, but lack the flexibility of eyes in a cockpit, suggesting a potentially important place for a low-cost, efficient light-attack aircraft equipped with precision-guided weapons.

At least this was the conclusion reached by USAF planners and formalized as a memorandum issued by Air Force Chief of Staff General David L Goldfein to the Air Force Strategic Development Planning and Experimentation (SDPE) office at Wright-Patterson Air Force Base (AFB), Ohio, on March 8, 2017.

The SDPE was tasked with coordinating the Light Attack Experiment (LAE), linked in media releases to the OA-X concept. Industry participated, providing four platforms for test missions from Holloman AFB, New Mexico, during August.

Three contractors supplied the four aircraft types, all but one of them turboprop powered. Textron’s Scorpion was the exception, with its twin-jet powerplant, the company also offering the AT-6 Wolverine, a weaponized version of the T-6 Texan II. An Embraer/Sierra Nevada Corporation (SNC) team furnished the A-29 Super Tucano from the Brazilian manufacturer’s Jacksonville, Florida, production facility, while Air Tractor/L3 fielded the Air Tractor AT-802L Longsword.

The experiment was largely without precedent in recent times, aimed neither at proving an experimental aircraft nor testing a new configuration of an established type; there was also no contract available to the winner, since there would be no winner.

The USAF is very familiar with the basic T-6, since the majority of US military pilots have trained on the type, while the A-29 has been operated and procured against foreign military requirements. The opportunity for inadvertent bias toward the familiar platforms was eliminated through careful, mission-focused operations.

Colonel Anthony Thomas, Air Force Life Cycle Management Center advisor to SDPE and a USAF Test Pilot’s School flight-test engineer graduate, explained LAE’s construct: “The work differed from normal test and evaluation, where we’d use a build-up approach applicable to a clean-sheet design. In this case we used a very disciplined and rigorous process to help gain knowledge on the systems.

“We were looking for off-the-shelf solutions and began the experiment with an air-to-ground mission set, examining what the airplanes could do and what their potential might be. None of them had been configured to match the specific set of criteria the government had provided, and they did the same things in different ways.”

OA-X?

LAE also wears an OA-X label, denoting ‘Observation, Attack-Experimental’ in US military parlance, suggesting a dual role capability – in modern times, observation generally equates to forward air control (airborne).

Thomas explains, “The OA-X designation comes from an Air Combat Command enabling concept from around a decade ago. The Light Attack Experiment was similar, but also very different, examining what a light attack platform might be, but LAE and OA-X, one an experiment, the other a concept, may never actually cross paths.”

On the subject of bias, especially toward the AT-6, Thomas says, “The test rigor we applied took into account the potential for natural human bias. We also used line aircrew [pilots and weapon systems officers (WSO) brought back from the frontline] as well as our own experimental test pilots, WSOs and flight-test engineers.

“The frontline aircrew often had multiple deployments behind them and expert knowledge in air-to-ground work; their expertise and insight were invaluable. Crews were instructed in the aircraft and became comfortable operating them, so in the execution phase they could focus on their assessments. We used contractor instructor pilots, but during the experiment, full ‘blue suit’ [frontline USAF] crews flew the A-29 and AT-6.

“We’ve used the T-6 for undergraduate pilot training for many years, but it was the specific air-to-ground systems of the missionized AT-6 that we assessed. Since it’s the mission system that delivers the capability, the issue of bias really isn’t there.”

Safety standards

“This concept of experimenting is something we haven’t done in depth since Vietnam. Since the first Gulf War [1991], the Air Force has been at a very high ops tempo and that’s stretching our equipment and people. Our mandate is to find ways of relieving that stress while still delivering the capability the combatant commanders need – experimentation is a great way to do that.

“But we didn’t do everything differently. We retained much of our well-proven test process and rigorous safety standards. Here in the Life Cycle Management Center we have the Air Force Technical Airworthiness Authority, which looks through a very technical lens to ensure systems meet Air Force safety and design requirements. They applied some of the world’s leading experts to subsystems the contractors had already been using and from that came the risk assessment. We were able to identify risk and ways to mitigate it, and present those risks to the appropriate decision authorities, which helped define the boundaries of what the experiment personnel could do.

“The Air Force Flight Test Center at Edwards [California] has the 704th Test Group at Holloman, expert at evaluating airplanes in a safe, auditable manner. Their safety processes also kicked in, applying their knowledge to what our subject matter experts had proposed. As a result, we completed a significant review of the aircraft in a very short period, examining their design and maintenance requirements, and applying a build-up approach to the flight testing.”

None of the aircraft were specially equipped with cameras, telemetry or other trials systems, but Thomas says the comprehensive test plan was built around data from head-up display (HUD) recordings, the data recording capabilities of the baseline aircraft (typically used for mission debriefing and system monitoring), and information gathered by flight-test technicians.

Gunfire, rocket launches and GBU-12/58 laser-guided bomb delivery were included for some types, but where weapons clearances had not been gained, platform compatibility had been demonstrated and no weapons integration/clearance work was undertaken under LAE. Similarly, targeting capabilities were assessed off the shelf, and Thomas reports, “It was a great knowledge gain for us, seeing how the manufacturers had used systems in different ways.”

He also expresses surprise and delight at the extent of the team involved in the experiment. Air Education and Training Command helped formulate the conversion syllabus, while the line crews were pulled from Air Combat Command and Special Operations Command. Air Force Reserve Command personnel were also involved, and maintenance personnel were drawn from a similarly deep pool.

With only four weeks available for the experiment’s execution, Holloman’s proximity to weapons ranges and the maintenance crews’ ability to turn the aircraft rapidly between sorties were critical to its success. “Thorough planning and understanding of range requirements enabled the team to put together a great data-collect program. And they were pushing the aircraft on turn time, collecting critical data on maintenance per flight hour. Each type typically flew twice a day and one time I saw multiple aircraft parked, taxiing and in the pattern.

“The experiment wrapped up at the end of August, and data analysis is ongoing. We’ve got preliminary results, then there’s a quick look, followed by a final report that’ll really get into the detail.”

Textron Scorpion

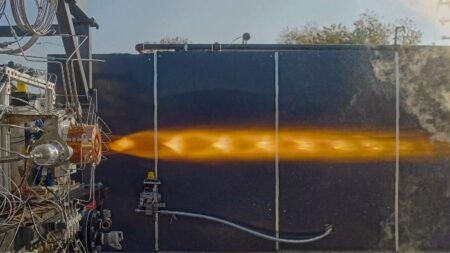

The Scorpion test team had completed its production aircraft weapons separation testing on July 18 (2017). Thanks to its twin 4,000 lb st (18kN) Honeywell TFE731 turbofans, the Scorpion was the fastest of the LAE aircraft with a maximum speed of 450kts, considerably more rapid than the turboprops but somewhat short of fast jet speeds. Textron supplied the second production Scorpion for the trial and its IPs trained USAF pilots for the LAE campaign.

Beechcraft AT-6 Wolverine

The AT-6 is a fully missionized version of the well-proven T-6 training aircraft. Like the Super Tucano, full frontline crews flew the Wolverine during the LAE process, and, in parallel with the Scorpion and A-29, it employed weapons over the ranges around Holloman.

Air Tractor/L3 AT-802L

Working with Moog, Air Tractor/L3 employed its fully armored Pratt & Whitney Canada PT6A-powered AT-802L demonstrator. The aircraft had previously been equipped with mission systems and received its airworthiness certification and military flight release on July 31, 2017, simultaneous with the announcement that it would participate in LAE. It completed its first of 17 LAE flights on August 7. Air Tractor instructor pilots (IP) primarily flew from Holloman as WSOs, while simultaneously serving as IPs, but also flew from the front seat with USAF WSOs.

The aircraft was not certified to employ weapons during LAE, although the AT-802L is proven with the Mk 82, GBU-12 and a 50-cal gun pod. It’s worth noting, however, that the AT-802L, in intelligence, surveillance and reconnaissance configuration, has a US Military Type Certificate and has been delivered under the Foreign Military Sales program.

Scorpion Statistics

All four aircraft proved exceptionally reliable during LAE, returning near maximum mission rates with a minimum of avionics and other glitches. Using the Scorpion as an example, the jet completed 20 out of 20 sorties for 44.5 flight hours accumulated during one or two daily flights across 14 flying days.

A team of five maintainers supported a campaign of eight familiarization, 10 experimental, and two combined familiarization/experimental sorties, flown by five USAF pilots, two USAF WSOs and two USAF flight-test engineers.

The aircraft expended four Advanced Precision Kill Weapons System (APKWS) guided rockets, 14 unguided rockets, two GBU-12s and 1,960 rounds of 50-cal ammunition.