The number of major commercial airliner development programs has been scaled back while OEMs and startups focus investment on early-stage R&D that will enable the next generation of more environmentally-friendly aircraft.

Some flight testing campaigns for the current generation of commercial passenger aircraft remain actively working towards certification, principally at Boeing. However work on the US planemaker’s forward-looking airliner development program, the X-66 also ramped up this year.

The NASA / Boeing Sustainable Flight Demonstrator is expected to be flying in 2028.

Meanwhile in Europe, Airbus continues to bet on hydrogen as the main future fuel for its aircraft. The company has many R&D programs developing different aspects of hydrogen aviation under its ZEROe program. Whether a ZEROe aircraft fleet will use hydrogen combustion or hydrogen fuel cell engines, or be made up of both types is yet to be decided.

Airbus’ only active flight test program for hydrogen combustion propulsion is using a glider, while only battery-electric aircraft have been flight tested so far the company’s engineers. The first Airbus hydrogen fuel cell propulsion system is planned to be flown onboard an A380 testbed in 2026.

Airbus

The European planemaker’s development flight test teams have continued to push boundaries across multiple aircraft development programs. Significant progress has been made on the A321XLR, while various engineering research and technology demonstrator projects achieved milestones. Notable examples include the A330-900neo, the EcoPulse hybrid aircraft, the RACER helicopter, and the hydrogen-powered Blue Condor.

A321XLR

The A321XLR program reached a pivotal moment in 2024 with the achievement of EASA Type Certification for the CFM-powered variant in July. This paved the way for the aircraft’s entry into service with Iberia, a significant step for the long-range single-aisle airliner.

The certification campaign involved intensive flight testing of two development aircraft: MSN11000 and MSN11058. MSN11000 focused on completing the CAT III Autoland system tests, which were conducted under various challenging conditions. These included a range of crosswind, tailwind and headwind scenarios, as well as different weight and center-of-gravity (C-of-G) states. Following these crucial tests, MSN11000 proceeded to finalize the remaining flight tests specific to the CFM engines.

Concurrently, MSN11058, equipped with Pratt & Whitney engines concentrated on testing the Rear-Centre-Tank (RCT) and its associated fuel system functionality. This parallel testing approach allowed Airbus to efficiently cover all necessary aspects for certification.

The successful completion of these main tests for the CFM-powered variant culminated in the submission of all required documentation to EASA. Since the maiden flight of the first A321XLR in June 2022, the program has made remarkable progress. Three dedicated prototype aircraft have collectively amassed approximately 1,450 flight test hours across more than 510 flights. This extensive in-flight testing has been complemented by rigorous ground tests, ensuring a comprehensive evaluation of the aircraft’s capabilities and performance.

A330-900 (Neo)

Airbus’ ambitious ‘hot-and-high’ testing campaign for the A330-900 flight-test aircraft MSN1795 took place in March 2023 and initiative aimed to validate aircraft and engine performance in challenging high-altitude, warm and humid airport environments. The campaign began with flights to Toluca, Mexico, where the airport sits at an altitude of 9,186ft (2,800m). From there, the aircraft proceeded to La Paz, Bolivia, home to an airport perched at a staggering 13,300ft (4,054m). During two weeks the team conducted extensive tests in these demanding conditions.

The primary objective of this certification exercise is to significantly expand the range of airports from which the A330neo can operate. The A330neo is certified for operations at airports up to 8,000ft in elevation. However, upon the successful completion of this campaign and subsequent certification approval, expected in before April 2025, the aircraft will be cleared to serve airports at elevations of up to 12,500ft.

This expansion of operational capabilities will open new routes and destinations for A330neo operators, enhancing the aircraft’s versatility and market appeal.

RACER Demonstrator

In June 21, 2024 Airbus’ “Rapid and Cost-Effective Rotorcraft” (RACER) high-speed demonstrator achieved its targeted cruise speed of 253mph (407km/h) at Marignane, France showcasing the potential of its innovative design.

First unveiled in June 2017, RACER is a compound helicopter that features two pusher propellers mounted on the tips of box-wings, complemented by a large lifting rotor. Power is provided by two Safran Aneto-1X turboshaft engines, connected via a sophisticated transmission system.

RACER’s design combines the vertical lift capabilities of a traditional helicopter with the forward thrust and wing-lift characteristics of a fixed-wing aircraft. This hybrid approach aims to deliver enhanced speed and efficiency without compromising the flexibility and versatility inherent to rotorcraft.

RACER’s first flight of a two-year flight test campaign happened in April 2024 and its target cruise speed was achieved after just seven flights and nine hours of flying. By July the flight test team has also already opened up 80% of Racer’s flight envelope, flown without autopilot in cruise and performed steep banking maneuvers at speeds above 230mph (370km/h).

During the remainder of 2024 flight testing of Racer was focusing on single-engine operations and finalizing the flight envelope. A hybrid-electrical eco-mode , which allows one of the two engines to be paused while in cruise flight to help reduce fuel consumption, was also being tested.

As well as cruise speeds of above 400km/h, Racer is targeting a fuel consumption reduction of around 20% compared to current generation helicopters from aerodynamic optimization and its eco-mode.

EcoPulse

November 2023 saw a breakthrough for the EcoPulse program with the completion of its first flight test in hybrid-electric mode. This milestone event occurred at Tarbes Airport in southern France, where the demonstrator aircraft took to the skies for approximately 100 minutes.

During the flight, the crew engaged the electric propellers and verified the proper functioning of several key systems. The systems verified included the flight control computer, high-voltage battery pack, distributed electric propulsion system and the hybrid electric turbogenerator.

The success of this first hybrid flight represents the culmination of extensive development and testing efforts. Before this flight, the EcoPulse team had conducted ground testing and accumulated 10 hours of flight tests with the electrical systems inactive.

Originally unveiled at the 2019 Paris Air Show, EcoPulse is evaluating the operational advantages of integrating hybrid-electric distributed propulsion in aircraft. A key focus of the R&D program is on reducing CO2 emissions and noise levels.

As the project progresses, the data it produces will be used by Airbus to provide insights into the potential of hybrid-electric propulsion systems in commercial aviation.

Blue Condor

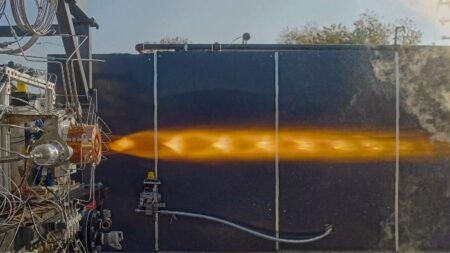

On November 8, 2023 Blue Condor completed its first hydrogen-powered flight in Nevada, USA. The modified Arcus-J glider had been fitted with a small hydrogen combustion engine by German company Aero Design Works.

The Blue Condor project was developed to study hydrogen contrails and non-CO2 emissions, providing data for Airbus’ hydrogen propulsion initiatives. This flight marked the company’s first-ever use of hydrogen as the sole fuel source for an aircraft, a significant step towards understanding the potential climate impact of hydrogen combustion in aviation.

Building on this success, early 2024 saw the project enter its next phase during Nevada’s cold-weather window. In these tests, a chase aircraft followed behind Blue Conor and used sensors to collect and analyze contrail formation, ice-crystal development, and atmospheric data.

The insights gained from the Blue Condor program are expected to play a crucial role in furthering the understanding of hydrogen combustion’s environmental impact. This knowledge will be instrumental in Airbus’s ambitious ZEROe program, which aims to bring a zero-emission commercial aircraft to market by 2035.

Boeing

Given the dynamic nature of the flight-testing process, with schedules and plans adapting to meet weather conditions as well as factors such as supply-chain uncertainties, Boeing does not provide detailed information about flight-test status or forward-looking schedules.

However, the USA’s flagship commercial aircraft producer has provided updates on several of its testing programs, with several models progressing through their journeys toward certification. Indeed, since the last Flight Test Roundup, marked advances have been made within the 737 MAX and 777X families, while progress has also been made in several other areas including its ecoDemonstrator and X-66 research programs.

737 MAX

Boeing’s 737-10, the largest airplane in the 737 MAX family, has continued to progress through its comprehensive flight test program, aligning with the certification requirements of the FAA. Specifically, the company has been focused on conducting a thorough and robust certification program that ensures the safety of the fleet and satisfies all of the relevant regulatory requirements.

The 737-10 flight test fleet includes three airplanes – 1G001, 1G002 and 1G003 – that have together flown more than 1,200 flight hours across 500 flights since Boeing’s certification flight testing efforts began in November 2023.

According to Boeing, the 737-10 offers greater capacity, increased fuel efficiency, and the best per-seat economics of any single-aisle airplane, and it is continuing to see strong customer demand for the 737-10.

777X

Elsewhere, Boeing has continued to work under the oversight of global regulators on all aspects of 777X development, including its rigorous test program for the 777-9. Here, the firm is focused on executing a series of tests and conditions, both on the ground and in the air to demonstrate the safety, reliability as well as performance of the aircraft.

With more than 1,200 test flights and 3,500 hours so far completed across its test fleet, Boeing said it is pleased with how the airplane performs as well as its reliability and availability for testing. Recent highlights include take-off performance testing, brake testing, crosswind testing and continued engagement with customer pilots in its simulators. In addition, the 777-9 has conducted gate fit checks to validate procedures.

In July, the 777-9 received type inspection authorization to begin certification flight testing with FAA personnel on board, with four 777-9 airplanes allocated to support the process: WH001, will test avionics/systems, brakes, flutter, ice shapes, low-speed aero, stability and control; WH002 will be used to test Autolands, ground effects, stability and control; WH003 will test the auxiliary power unit, avionics, flight loads, propulsion performance such as inflight engine starts and WH004: environmental control system, ETOPS, functionality and reliability, noise.

ecoDemonstrator

In addition to its commercial flight testing much of Boeing’s ongoing R&D efforts have centered around its ecoDemonstrator program in the past year. Having been first launched in 2012, the program is focused on improving the efficiency of aviation, serving to both minimize the sector’s environmental footprint as well as enhance safety.

11 aircraft have served as flying testbeds for ecoDemonstrator, with Boeing having expanded the program further in 2023 with Explorer aircraft that are focusing on the short-term testing of individual technologies.

In October 2023, one of these Boeing ecoDemonstrator Explorers – a 737-10 destined for United Airlines – partnered with NASA, GE Aerospace, the FAA and the German Aerospace Center (DLR) to study the effect of sustainable aviation fuels on persistent condensation trails, or contrails. While their full impact is not yet fully understood, some research has suggested certain contrails can trap heat in the atmosphere.

During 11 flight tests, the 737-10 used 100% SAF and conventional jet fuel in separate tanks and alternated between them to compare the emissions produced by each fuel. NASA’s DC-8 Airborne Science Lab followed behind the 737-10 to measure emissions and contrail ice particles, while the use of satellite imagery provided information on persistent contrail formation.

Then, in December, in partnership with Nav Canada, which owns and operates Canada’s civil air navigation system, Boeing tested a new electronic flight bag (EFB) capability to coordinate digital clearance to the airplane for taxiing to the gate upon arrival, or toward the runway for departure. The capability features Smart Airport Maps, a component of Jeppesen FliteDeck Pro, and provides a graphical depiction of the taxi instructions. The testing focused on how digital clearances and maps can improve pilot workflows, strengthening pilots’ situational awareness and operational efficiency for airlines.

Most recently the company announced it would continue to use a 777-200ER (Extended Range) aircraft to test technologies focusing on operational efficiency, reducing airport noise, and improving the cabin environment. These projects include: Quantifying the benefits of flight operation procedures, like steeper glide slope and continuous descent approach to reduce community noise, fuel use, and emissions; lighter, recyclable, and more durable floor coverings and cabin insulation to reduce noise and regulate humidity and temperature.

X-66

Boeing subsidiary Aurora Flight Sciences is also working on several innovative projects. These include working with NASA to build, test and fly the full-scale X-66 demonstrator aircraft – NASA’s first experimental plane aimed at helping achieve the goal of net-zero aviation greenhouse gas emissions. NASA awarded Boeing the contract for the Sustainable Flight Demonstrator project in 2023.

Aurora Flight Sciences will perform extensive modifications on an MD-90 airplane to test the X-66’s Transonic Truss-Braced Wing (TTBW) configuration. With ultrathin wings braced by struts with larger spans and higher aspect ratios, the TTBW design and other expected technological advances could lead to reductions in fuel use and emissions by up to 30%.

Over the next year, the X-66 program will focus on advancing the technical maturity of the aircraft, with wind tunnel testing, spatial integration activities, and vehicle requirements verification and validation. Boeing will also begin preparations for initiating the heavy modification work on the MD-90, including removal of the wings and forward body fuselage sections. Ground and flight testing, meanwhile, are expected to begin in 2028.

As a demonstrator aircraft, the X-66 is meant to shape a future generation of more sustainable single-aisle airplanes. Boeing and NASA have collaborated for more than a decade on the TTBW concept through the Subsonic Ultra Green Aircraft Research (SUGAR) program.

X-65

Alongside this, Aurora has begun manufacturing the X-65 experimental aircraft for the Defense Advanced Research Projects Agency (DARPA)’s Control of Revolutionary Aircraft with Novel Effectors (CRANE) programme.

X-65 is designed for testing and demonstrating active flow control (AFC) which has the potential to replace traditional flaps and rudders for flight control and may deliver benefits in areas such as aerodynamics, weight, and mechanical complexity. X-65’s AFC system supplies pressurized air to 14 AFC effectors embedded across all flying surfaces, including multiple wing sweeps. The aircraft is configured to be modular, featuring replaceable outboard wings and swappable AFC effectors, which allows for future testing of additional AFC designs.

The manufacturing phase of the program follows three years of work, across Aurora and Boeing, in design conceptualization, preliminary and detailed design, wind tunnel testing, AFC system testing, and more. The program will culminate in flight tests of the full-scale, 7,000 lbs (3,175kg) X-65 aircraft at speeds up to Mach 0.7, with these targeted for 2025.

Embraer

Brazil’s multinational aerospace manufacturer delivered 181 aircraft in 2023, up 13% year over year, while its backlog also rose by US$1.2 billion to reach a total of US$18.7 billion – the highest figure recorded by the firm since 2018.

This healthy pipeline has been accompanied by several milestones. In 2024 Embraer’s Phenom 300 series maintained its status as the world’s best-selling light jet for the twelfth consecutive year, and best-selling twinjet for the fourth year running, according to data released by the General Aviation Manufacturers Association (GAMA). In May 2024 the company also celebrated the delivery of its 1800th E-Jet production aircraft.

E190-E2 and E195-E2

Embraer’s E-Jet E2 family of narrow-body airliners have contributed significantly to the firm’s successes in the last year with orders from Porter Airlines, Mexicana de Aviación and the American Airlines Group. The first E2 were also delivered to the airlines Azorra and Royal Jordanian, while LOT Polish Airlines began operating leased three E195-E2s.

Embraer said it is continuing to focus on the E2’s durability with its ongoing developments. The E2 jets offer the longest maintenance intervals in their class, with 10,000 flight hours between basic checks and no calendar limit, allowing for 15 additional days of aircraft utilisation over ten years compared to previous models.

Sustainable aviation

Sustainability is a core focus of Embraer’s R&D and testing programs, with the company aiming for net-zero emissions by 2050 and to be carbon neutral by 2040. In the past year, Embraer has sought to strive closer to its environmental goals through several partnerships. In February 2024, it joined the United Airlines Ventures (UAV) Sustainable Flight Fund, which aims to scale SAF (sustainable aviation fuel) supply through investments in startups. The fund, launched in 2023, now includes 22 corporate partners and over US$200 million in capital.

This year the company’s innovation incubator Embraer-X announced partnerships with Sustainable Aero Lab and Greentown Labs to accelerate the development of climate solutions for sustainable aviation.

(Image: Embraer)

eVTOL programmes

Embraer is also targeting several important R&D milestones for urban air mobility through Eve, the independent eVTOL development company it founded in 2020.

This year, Embraer announced that Eve had secured US$94 million from private investors. Eve has started assembling its first full-scale eVTOL aircraft prototype, with test campaigns scheduled to begin in 2026. The company has a letter of intent with AirX, Japan’s largest public helicopter air charter service, for an initial 10 eVTOL with the option for another 40. It has also signed an agreement with SkyScape, a Japanese vertiport development and management company, who plan to use Eve’s Urban ATM (air traffic management) as part of Japan’s Advanced Air Mobility (AAM) operations.

But the culmination of Eve’s year was when the company revealed its first full-scale prototype on July 21. The eVTOL will complete a series of test campaigns designed to assess every aspect of the aircraft’s operation and performance, the company said.

COMAC

The Commercial Aircraft Corporation of China (COMAC) is in the process of designing its first wide-body jet the C929. In March 2024, the company announced it was in the detailed design stage, with delivery of the first fuselage section slated for September 2027.

According to COMAC, the C929 will have around 280 to 400 seats and a range of 7,450 miles (12,000km). The March announcement is significant because it indicates the firm is willing to develop a wide-body aircraft alone following the breakup of its joint venture with Russia to build the then-named CR929 in August 2023.

In another important development, China opened a new dedicated flight test base for civil aircraft in Pucheng County, Shaanxi Province, in June 2024. The first of its kind in the country, the base is around (40km) from Yanliang Airport, China’s largest military aircraft flight test base and home of the AVIC Flight Test Institute.

Meanwhile, in 2023 we reported that COMAC had celebrated the first commercial flight of its C919 narrow-body aircraft. Since then, COMAC has moved into full commercial production of the model, which is the first airliner independently developed by China by international airworthiness standards.

This comes off the back of a sizeable order from China Southern made in April 2024. The deal, worth around US$10 billion, is for 100 C919s which will be delivered between now and 2031. This follows nearly identical orders placed by Air China and China Eastern Airlines.

The C919 is displacing the ARJ21 regional aircraft as its hero product. The ARJ121 entered commercial operation in June 2016. Since then, 117 aircraft have been delivered to customers such as Air China, China Eastern Airlines, China Southern Airlines, Chengdu Airlines, Genghis Khan Airlines, Jiangxi Air, China Express Airlines, and TransNusa, carrying more than 10 million passengers.

The C919 made its testing debut in November 2015 when the first aircraft rolled off the production line. Subsequently, in May 2017, the C919 successfully completed its maiden test flight. Five years later, in September 2022, the aircraft received its Type Certificate from the Civil Aviation Administration of China (CAAC).

United Aircraft

State-owned Russian manufacturer United Aircraft (UAC) announced delays to the development timelines of two commercial aircraft during 2024.

In a press conference in March, Rostec boss Sergey Chemezov admitted that the production of fully domestically manufactured versions of the Superjet 100 (SJ-100) and MC-21 will take up to two years longer than initially expected.

The MC-21 is a single-aisle airliner designed to carry between 163 and 211 passengers. It features an extended wingspan, and extensive use of composite materials and is intended to rival mainstream airliners like the USA’s Boeing 737 MAX and the European Airbus A320neo.

Static rig testing for the MC-21 aircraft was completed in 2022 by the Central Aerohydrodynamic Institute Ground-based emergency landing tests have also been performed. In August Irkut completed the construction of the first MC-21-300 aircraft with a Russian-made polymer composite wing and transferred it to the test division, where strength testing of the horizontal stabiliser was conducted in September.

Meanwhile, the first SJ-100 regional jets were scheduled to be certified and delivered to Russian launch customer Aeroflot in 2023.

Both aircraft have been hampered by sanctions placed on Russia by the USA, EU and other western states – cutting off the supply of western components, including Pratt & Whitney PW1400G engines which were supposed to power the MC-21.

UAC’s ambitious production target for the MC-21 is reported to be to produce 270 units by 2030, although as of October 2024 it remains unclear as to when the first fully import-substituted version of the aircraft will embark on its first flight. According to ch-aviation data, five airlines have placed orders for 291 MC-21 aircraft.