by Dave Hughes

When electric engine company MagniX needed to find commercial aircraft operators with short haul routes to certify an engine, two small seaplane operators turned out to be perfect partners.

Each operator, one in Seattle and the other in Sydney, Australia, has something MagniX needed – commercial airplanes flying short routes and a willingness to modify them with electric engines. Both companies operate seaplanes in a pristine marine environment and want a certified electric engine to replace a traditional turboprop for the first time for environmental reasons.

Harbour Air in Vancouver, Canada and Sydney Seaplanes in Australia provide charter, sightseeing and scheduled airline services. Both have been struggling with reduced activity as the result of Covid-19. If the projects with MagniX to electrify Harbour Air’s Beaver aircraft and Sydney Seaplanes Caravans result in Supplemental Type Certificates (STCs), the companies will be making aviation history.

The projects aren’t large, but the people involved are determined in the way aviation pioneers must be. As early adopters of electrification technology, they could leave Boeing, Airbus and major airlines trailing.

Flight testing has already begun and it is believed the well-established nature of the airframes being used will shorten the path to electric engine certification.

Seaplane fleet

Harbour Air of Vancouver in Canada is working with MagniX, Transport Canada and the FAA to get an STC on what will be known as the eBeaver – a six-seat de Havilland Canada DHC-2. About 120 miles (190km) south of Harbour Air’s headquarters, MagniX recently moved into a 40,000ft2 headquarters and development center near Seattle, USA.

Harbour Air was founded in 1982 by Greg McDougall using two de Havilland Beavers to fly loggers to camps in British Columbia. Today, it carries 450,000 passengers per year on short routes using a fleet of 44 aircraft including 14 Beavers, 22 single engine Otters for 14 passengers and three twin Otters for up to 19 passengers and one Caravan. The company is the largest seaplane airline in North America.

Harbour’s busiest route is between Vancouver on the coast of Canada to Victoria on the island by the same name. No Harbour Air route involves more than an hour’s flying time.

McDougall says Vancouver harbor to Victoria harbor avoids airports and hassles and describes the route as a form of urban air mobility (UAM) – transporting passengers from the heart of one downtown to another. Another route from Victoria harbor to Seattle lands passengers at a downtown offload point with a very short line to clear US customs.

McDougall is a traditional aviator but also likes and studies disruptive technology – he owns a Tesla. He notes that the car is never in the shop for service. So, when MagniX contacted Harbour Air he was willing to form a partnership, funded in part by the engine company and government grants.

Harbour also provides its expertise in Beaver modifications, labor and parts led by the vice president of maintenance Shawn Braiden and Erika Holz, the engineering and quality manager. The test pilot is Harbour Air’s Eric Scott, vice president of flight operations and safety.

McDougall has 10,000 flying hours and flew the first flight test in the eBeaver prototype on December 10, 2019. After seven hours of testing for proof of concept that electrifying a Beaver would work, the certification process began. The data collected showed cruise performance and take-off thrust efficiency.

These first flights also tested electromagnetic interference issues and battery management software logic. Since then, the company has been working on battery and motor modifications to the prototype with tests set to resume shortly.

Approval process

MagniX provides the entire electric propulsion system on the eBeaver, including the engine and the inverter. McDougall notes that the engine is quiet, resulting in a more comfortable passenger experience.

In addition, the engine only produces a small amount of heat compared to the Pratt & Whitney Canada PT-6 turboprop it replaces, which runs at a temperature of 850˚C (1,600˚F). The high heat of the turboprop engine causes wear and tear that requires maintenance while the electric engine that replaces it on the Beaver has no gearbox and many fewer moving parts.

STC approval is expected to take another two years. McDougall says that all Harbour Air has to focus on is the electric propulsion system and the battery, not the airframe. The lithium-ion battery issues that must be addressed for the STC include how to ensure safety for passengers and crew if the 800 volt battery gets wet.

The battery also has to be crashworthy for aviation certification and issues such as a thermal runaway have to be addressed. There are lots of data collection flights remaining to be done and then there will be prototype improvements and retesting required.

Interest is high in the project, particularly about when the system will be certified. “That’s the 24-million dollar question,” McDougall says. “When we are finished we will be happy to provide guidance and support to any other industry efforts towards the electrification of aircraft.”

MagniX CEO Roei Ganzarski says, “Battery technology is improving rapidly. There is a huge investment and push forward in batteries.”

According to Ganzarski a battery that produced 145-watt hours per kilogram in 2019 will deliver 300 watts today. Better batteries will allow aircraft with electric engines to “deliver more payload and range without changing anything. That doesn’t exist anywhere else in aviation,” Ganzarski says.

On the first flight the Beaver was fitted with a heavy battery originally designed for use in space. With McDougall at the controls, the aircraft was at maximum gross weight but the engine torque was so high and instantaneously available that “the aircraft leapt out of the water and climbed like crazy,” he says.

With the energy density of the lithium-ion battery used in the next phase of testing, McDougall says he could fly 20-minute flights with a payload and by the time the STC is complete that could be up to 48 minutes with an improved battery.

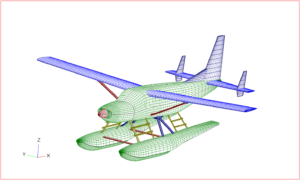

MagniX is also involved with electrifying the Cessna Caravan 208B. It worked with AeroTEC, the aerospace testing, engineering and certification company, and conducted a 30-minute first flight at the engineering firm’s flight test center at Moses Lake, Washington during May 2020.

The MagniX 500 propulsion system installed on the Caravan is the same model being used in the Beaver flight tests. MagniX calls the Beaver and Caravan “middle-mile” aircraft used to move people and cargo on short haul routes for decades. “There is no roadmap for testing and certifying electric aircraft, this is a new frontier,” says Lee Human, president and CEO of AeroTEC.

Caravans in Sydney

Following the May flight tests, in December 2020 MagniX formed a partnership on an eCaravan certification effort being run by Sydney Seaplanes in Australia. The operator provides a sightseeing and scheduled service business out of Sydney Harbour with amphibious Caravans on floats that can land on water or on runways.

Another partner in the project, Dante Aeronautical is handling the aerodynamic testing aspects. The goal is to work with the Australian Civil Aviation Safety Authority (CASA) to achieve the first eCaravan STC in the world by 2023 and market it throughout the Asia Pacific Region.

The team is also working with the European Union Aviation Safety Agency to see if the STC can be approved for sale in Europe. There are many land-based Caravan operators in the Asia Pacific region and some that use Caravans

on floats.

“We are having ongoing discussions with CASA because there are no regulations in Australia currently to certify this type of aircraft,” says David Doral, who is the co-founder and CEO of Dante Aeronautical. “The plan is to demonstrate in ground testing that the powertrain is robust enough before starting flight tests at Sydney later this year. Those tests may last until 2023, then we will work with CASA to create the new regulation.”

During the summer Sydney Seaplanes operates six aircraft and up to four in the off season, including amphibious Caravans and a twin Otter. “We are a small company but we are passionate about this technology,” says the company’s managing director, Aaron Shaw.

Sydney Seaplanes flies regularly from Sydney Harbor to a lake in downtown Canberra, Australia’s capital city, less than 200 miles (320km) away. Shaw is looking forward to doing this with an existing airframe, a Caravan, equipped with emission free and quiet electric engines.

After equipping his amphibious Caravans, he wants to sell the STC to customers in Australia, New Zealand and the Pacific Islands who have Caravans that land in water or on runways. He estimates the cost of retrofitting a Caravan from a turboprop to an electric power plant will be about AUD 1 million (US$760,000).

“We have worked in Asia a lot, helping countries set up regional seaplane operations in Vietnam, Indonesia, Malaysia and China,” Shaw says. In a few years Sydney Seaplanes will be able to show them how to electrify seaplanes to gain environmental benefits as well.

Shaw believes an advantage of battery power for a Caravan in remote regions is that they fly to airports where it is difficult to carry fuel in by truck. It would be possible to use solar or wind power to keep some batteries constantly charged and available for use by transiting Caravans.

The aircraft are also used in Antarctica, where the same technique would side step the logistics hassle of providing fuel depots at icy landing fields. Shaw said he already has solar panels on the roof of his headquarters building and could add them to an adjacent hangar in Sydney to recharge batteries. Shaw also hopes the use of hydrogen to power the electric engine would also provide more range for commercial flights.

Sydney Seaplanes hasn’t selected a hydrogen system partner yet but is talking with ZeroAvia. The London and California-based company has completed a hydrogen-fuel cell powered flight using a modified Piper M-class six seat turboprop aircraft at Cranfield airport in the UK during September 2020.

Shaw says, “I think our businesses exist because of the beautiful environment we operate in. We have a responsibility to assure that we are at the forefront of sustainable aviation activity. That for me is the real driver for this. We don’t want to be a spectator to this technology that may be adopted at the end. I would rather be part of the process.

“We want to be the first commercial all-electric aviation service in the world,” he says.

Harbour Air is already in flight test and either the Canadian company or Sydney Seaplanes, or another operator might get their first. The race is on.