Non Destructive Testing is a growing and increasingly essential area for aerospace test engineers and technicians composed of a number of different disciplines – each is a branch of applied physics.

“A career in NDT should never stagnate, there is always the opportunity to diversify into a different method, or to specialize in one method to an advanced level of competence,” says Sam Cunningham, non-executive director, and trustee of the British Institute of Non Destructive Testing.

NDT is practiced in a diverse range of sectors, which means a range of qualifications are relevant to the profession. Exactly, how an individual starts a career in the NDT industry can also vary a lot.

“An aspiring technician may choose to attend a two-year college program that specializes in training for the various NDT methods,” explains Roger Engelbart, a past president of The American Society for Non Destructive Testing (ASNT) and a retired aerospace NDT engineer.

“He or she would then seek employment that would provide experience and a path to achieving certification.”

Most technicians start off as trainees in an organization and spend the first year learning one or two specific methods. “As they gain experience they tend to open up to additional methods and materials. Usually, a technician with five years of experience should have a good grasp with Level 2 knowledge and experience in at least three to five different methods,” says John Stewart, the executive director and founder of the American Aerospace Technical Academy, a non-profit training organization.

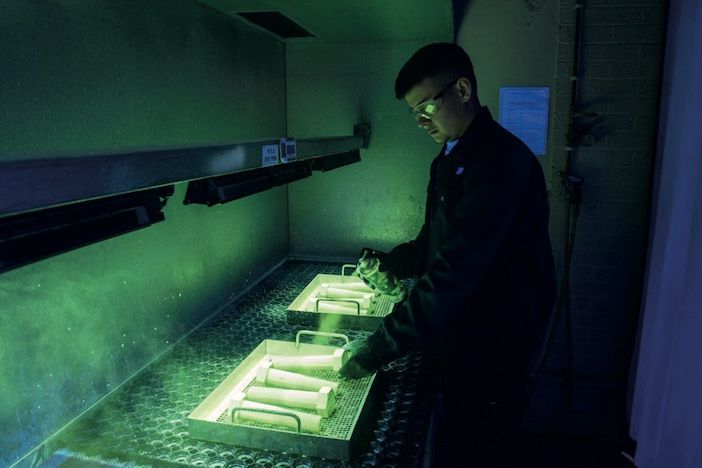

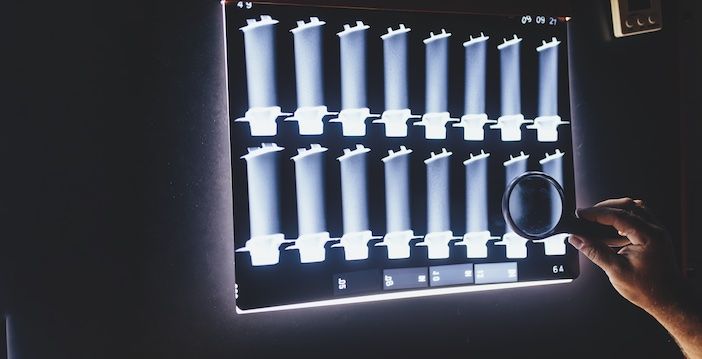

These methods include Ultrasonic Testing, Radiography Testing, Magnetic Particle Testing, Penetrant Testing and Visual Testing.

Engineers, researchers, and academics often become interested in NDT through other fields of science and engineering. “Not many educational institutions offer four year, comprehensive programs of study in NDT,” says Engelbart.

“The academics are often also researchers who have become interested in aspects of NDT research and who have influenced students to join their projects.

“Such encouragement results in the development of new researchers and new engineers who want to specialize in NDT.”

Career development

Once someone has established a career in NDT, the training does not stop. That NDT practitioners have the latest relevant training and qualifications is vital for the aerospace industry, as errors can have disastrous consequences. NDT operators therefore must refresh their skills and knowledge regularly, attending training courses and taking examinations.

Continuing Professional Development (CPD) is understood across most professions as the systematic acquisition of knowledge and skills and the development of personal qualities to maintain and enhance professional competence. Within NDT, it is expected that individual members will undertake CPD to maintain their professional standards.

“Those who hold NDT certifications have to re-certify periodically and must maintain their activity in the field and their inspection skills to do so,” says Engelbart.

“Certification must be maintained through continuous work experience, continuing education which can count towards recertification points and learning new technology certifications such as electromagnetic acoustic transducers, infrared thermography and laser shearography,” says Stewart.

Joining an organization such as ASNT or BINDT also provides networking and support with a broad range of professionals and helps to maintain awareness of technical advances and career opportunities.

Technical advances

Over the past 30 years NDT has made remarkable advances. New NDT methods have been introduced, while old testing methods are continually improved.

“Although some NDT methods have drastically changed over time, the principle behind each method has remained the same – to test and evaluate materials without causing damage or destruction to it,” says Cunningham.

The introduction of Artificial Intelligence (AI) for defect identification and analysis, software to determine material thickness and densities, non-contact inspection technologies such as air-coupled ultrasonics, laser shearography and infrared testing, mean that the field of NDT is constantly changing.

NDT Technician

“You need to keep up with the new procedures,” says Paul McNeill, a Level 3 Instructor at Aerospace Inspection Training (AIT). “The procedures are always being updated as better ways are found to inspect parts or the aircraft. The technology and the materials in the aircraft are constantly changing, so it is always good to keep current.”

Keeping up with advances in NDT methodologies is important, but so is keeping up with changes in the instruments and tools for those methods.

“There is a desire for greater fuel efficiency and greater safety from all forms of transportation. This means designing more reliable engines and maintaining structural efficiency while reducing weight. This leads to tighter acceptance criteria and the need for more exacting inspection procedures and more quantitative data,” says Engelbart.

Computer skills are also increasingly important for NDT operators as the software for NDT instruments becomes more complex.

“Computer skills are important, due to the increasing complexity and capability of available instrumentation. This means that effective performance of NDT is reliably extracting the desired information from the inspection process in as short a time and as cost-effectively as possible,” says Engelbart.

Stewart agrees, “Ultimately AI and robotics will have a larger role in inspection, so I’d say the industry needs to start gearing up at school level to try and keep up with new technology.

“The younger generation understand computers a lot better than us older guys. When things change, so does what we have to teach at the training schools.”

A focus on the latest technologies cannot be established without a good foundation in the basic concepts. In addition, not every engineer has the latest tools and equipment at their disposal. “We have to teach the older ways as well as the modern ways because not all companies can afford to keep up with the newest equipment due to cost,” McNeill says.

“With the increased need for quantitative inspection information, the practitioner must be more experienced with computer-based systems and better versed in digital methods and digital data forms.

“The practitioner must also be more acutely aware of the impact of design for inspectability on the effectiveness of the NDT process,” says Engelbart.

Skills shortage

A challenge that the NDT sector is facing is the gap between the supply and demand of trained technicians. It’s no secret that the NDT profession has an ageing profile and with many of the most experienced technicians approaching retirement age, there is a push to encourage the next generation to enter the world of NDT.

“There is a skills shortage, particularly for experienced technicians. Many who have spent their entire careers in the field are at, or near retirement age,” says Engelbart.

“Companies are interested in finding workers who can quickly come up to speed on performing inspections and making accept / reject decisions. Part of the mission of the ASNT is to promote the field of NDT as a career choice to ensure such a pipeline.”

McNeill agrees, “I get asked on a weekly basis do I know of someone who wants to train up or already has the qualifications. I have companies I am the responsible Level 3 for who are still looking for technicians after many months.”

Meanwhile the existing workforce of technicians are increasingly expected to be trained to be

multi-disciplined. “You can be doing penetrant testing on castings in the morning and ultrasonic testing on composites in the afternoon,” says Stewart.

Diversity within NDT

A more pressing issue connected to the skills shortage is the industry’s lack of representation of woman and minorities in the NDT profession.

“Employers must do a better job in recruiting and creating diversity and inclusion in the industry,” says Stewart. “It’s time to grow up and stop the bias that is hurting the industry.”

“There is just not as many women and minorities as we would like to see, especially in the technician ranks,” says Engelbart.

“Over the last eight years working at AIT, we have had a very small number of women come in for training and have trained five ladies in one of my customer’s group, which is great to see, but it’s only a start,”

says McNeill.

There is slightly more diversity in academia as young researchers enter the field. Some women are introduced to NDT through industry internships that took place during their time at college and they have elected to stay in the field, working as NDT engineers.

There are many paths to the field and there really is no typical practitioner, but one thing is for certain

when it comes to being an NDT technician, you never stop learning.

“The more knowledge, experience and certifications you hold, the more you are an asset to your employer,” says Stewart. “Anyone with the right attitude and hustle can become very successful in NDT.”