The Power Electronics and Machines Centre is a bright and modern laboratory with offices on the outskirts of the city and the University of Nottingham’s Jubilee Campus.

The 5,000 square meter (54,000 square foot) dedicated building opened three years ago and is a major upgrade over the laboratory’s previous home as part of the University’s electrical engineering department, which was famously housed inside an imposing concrete tower block built in the 1970s.

The significant increase in size and advanced testing capabilities reflects the growth in demand for electrical propulsion systems as transport sectors electrify to eliminate carbon emissions. The Power Electronics and Machines Centre (PEMC) develops and test large high voltage, high-power electrical machines. It was built to shape the electric future of the automotive and aerospace sectors. With space and the plans to expand, it is a clear indication of the future growth in the importance of motors, generators and power electronics to aviation.

Industrial testing

Speak to almost anybody at the PEMC and the conversation will include units like Kilovolts and Megawatts. It is soon to be the only AS9100 laboratory on a university campus in the UK and is dedicated to R&D – there are no students in the building. The £40 million (US$50 million) PEMC works with industry on projects up to TRL six, – higher than would typically be associated with academic research. Companies are also testing commercially available motors in the laboratory to produce product data sheets.

At their previous laboratory, PEMC researchers would work on devices in the 10 to 150kW range for aerospace applications. Now they build and test propulsion systems at power levels of between 2 and 5MW for use in aircraft.

Chris Gerada is the zero-carbon cluster lead and professor of electrical machines and has worked at the University of Nottingham for more than 20 years. He says, “We have moved from working on starter motors and compressors for cabin pressurization to electrifying entire propulsion systems in a matter of years.

“We work across the entire system – the machine providing the power, the power electronics that control it and the thermal management that cools it. And we can take care of the mechanical and electrical interfaces with the outside world. If you want to do electric propulsion, we are a one-stop shop.”

The PEMC has already hosted projects worth €56 million under the EU-funded Clean Sky 2 program. A recent program saw researchers at the Centre develop a 2MW power unit motor to drive a propeller for an 80-seat hybrid-electric aircraft that went as far as TRL 4. It was designed, built and tested solely at the PEMC over three years.

Such successful programs mean the University has been allocated four projects worth €10 million (US$13 million) in the first round of Clean Sky 2’s successor program, Clean Aviation. These are running over the next few years.

Gerada says, “An advantage we have is that we can easily see and access what is happening in other sectors. We do not have the legacy that some aerospace companies and mechanical engineers do around electrical engineering being difficult. We can start with a clean sheet and hit the power density and efficiencies needed within a range and make it reliable.”

metal deposition

Key requirements

In electrical systems for aircraft power density and reliability are the key challenges. Failure rates higher than in mechanical systems mean that there must be lots of redundancy in an electrical system. This creates weight, a particular negative for aircraft where the aim is to be as light as possible.

A focus for PEMC research has therefore been automated and precision manufacturing of the windings for motors. Current manufacturing practice for windings in motors is manual, leading to almost random windings. Precision manufacturing enables patterned and regular windings and a reduction of voltage stresses between coils. This minimizes the occurrence of hotspots in motors, which improves reliability and reduces the amount of redundancy necessary.

“Power density, efficiency and reliability are not where we need them to be yet for aviation, but we are rapidly closing the gap,” says Gerada. “New designs, materials and advances in manufacturing technology, mainly from automotive adapted for the low volume, high performance world of aviation are getting us there.”

The main laboratory in the middle of the PEMC is a cavernous space with rows of test benches and a large 4.5m x 5.7m (15ft x 19ft) roller door at one end for moving in large pieces of equipment. On the test benches are motors and drive units at various stages of build, some attached to dynamometers, cables, PCBs, control systems, power supplies and propellers. The space is flexible so it can accommodate multiple test and development programs simultaneously.

Some generators tested at the PEMC for use in ships are almost 3m in diameter, akin to what would be seen in a power station. However, the challenge for aerospace applications is to make things smaller and more efficient – to increase power density and reliability – a very demanding goal.

“A lot of the time we are dealing with high voltages, controls and cooling, while trying to find the faults in very big things – which is challenging,” says Gerada. “But small machines are also difficult to test. You need to have accurate measurements for the machines with very high speed and low power.”

One defense project has required the integration of power electronics inside a motor coil. “If you are transporting and installing it, you want to put it in one container and not have another container for the electronics,” says Hitendra Hirani, sales director and general manager of Nottingham Drives Specialist Services, the industry-facing arm of the PEMC.

An area of the laboratory is sealed off for testing high-pressure fluids. The thermal issues from increasing power density and reducing the size of electrical equipment often means engineers are dealing with high-pressure fluids for cooling as well as higher voltages and power levels. There are also several altitude and temperature test chambers for testing systems in aviation-like environments up to 70,000ft high.

“We can do performance testing, functionality, durability, endurance testing. You name it, we can do it,” says Gerada. “We can do some crude cryogenic testing and we are investing in an advanced cryogenic facility.”

High power and prototyping

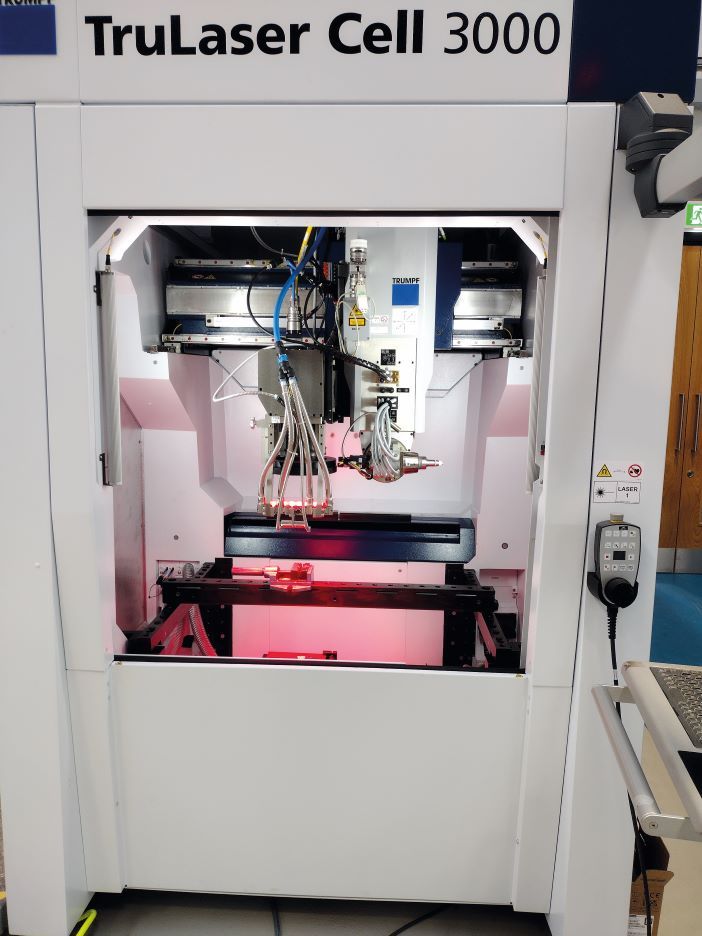

In a separate area in the main laboratory is a large workshop for building prototypes which features a mix of features traditional manufacturing equipment and 3D printers. It includes balancing equipment and winding machines. As well as in-house manufacturing capabilities, the PEMC has links with 129 companies in the local area that can produce things like casting and metal parts for motors.

On one side of the main laboratory is the high-power testing area, which performs characterization of motors for commercial use. The loud whirring of the equipment here betrays the high rpms the machines are running at. The laboratory features trenches for the high-power cabling and several large dynamometers in test cells, ranging from hundreds of kilowatts in size to 2MW. A 5MW dynamometer is being installed next year.

“We have put a lot of effort into designing the 2MW to be flexible for aircraft propulsion use. It has a gearbox that goes from 800 up to 36,000rpm and it can do transverse load too, so it can emulate propeller loads,” says Hirani.

Some of the test cells are within environmental chambers capable of recreating aircraft flight cycles. This approach reduces the cost of development. One high-speed testing machine able to reach 120,000rpm is buried in the ground with a lid over it to prevent accidents. “When we are testing something that has a higher risk of going bang, because we are testing in overspeed or trying to understand the limitation, we put it in there,” says Gerada.

The dynamometers cost millions. The overall investment for the high power laboratory is around £26 million (US$33 million). The PEMC requires £0.5 million (US$635,000) a year to run, so funding has to come from industry.

NDT and electromagnetics

Meanwhile, on the other side of the main laboratory is a quieter area for materials and EMC testing. Here engineers conduct vibration, temperature and power tests as well as NDT. There are contact measuring machines (CMMs) and an EMC chamber.

This laboratory tests parts of electrical equipment, power modules, connection bonds and power electronics. These are then built up into systems before testing in the high-power area.

The materials and EMC area also has a facility for magnetic materials, which places them under the thermal and pressure stresses of an aviation environment in accelerated life tests. Although data on materials may already exist, how magnetic materials will behave in an aviation environment is often unknown. Hirani says, “You need to understand the physics of what is going on, with datasheets for the duty cycles in your end application to design components in the best way for aerospace.

“All of the knowledge from the testing we do of magnetic materials goes into our design tools and is used to make the motors and power electronics here. Our chain of R&D, design, manufacture and test has the same experts working across the development, it is the main difference at the PEMC. Everything is underpinned by understanding the theory and having the test and validation data for it.”

Partnership potential

The PEMC is looking to partner with aerospace companies in the UK and internationally on electrification and hybridization projects. Hirani says, “We can test anything from a 50kW motor up to 5MW, it’s really difficult for industry to have these kinds of facilities themselves.

“We engage with the customer to understand their requirements and timescales and help them define a test program. We look at what data they need to get confidence in their application. Our critical capability is accelerated life testing, an area we excel in because we do it every day.”

Despite the novelty of the PEMC, the University of Nottingham is already applying for £90 million (US$114 mllion) to build another R&D and test laboratory. The Zero-Carbon Translation Center will combine expertise and knowledge from the PEMC with laboratories in other areas of the campus that specialize in manufacturing and materials, hydrogen, batteries and next generation fuels.

Gerada says, “The PEMC builds prototypes. The Zero-Carbon Translation Centre will be able to build, thirty or forty propulsion systems, enough for qualification testing. It will help de-risk industrial projects and increase investment in emissions-free aviation.

“We want people who are interested and have a vision like this to come and talk to us about what their testing needs will be.”