by Dr Filomeno Martina, founder and CEO, WAAM3D

Worldwide, the wind tunnel market is expected to grow to US$3.19bn in 2027 at a CAGR of +3.3%. Since the first enclosed wind tunnels became operational back in the 1800s, they have proved their value in aerodynamic investigations and have been a fundamental contributor to every major aircraft program. As unmanned aerial vehicles (UAVs) become increasingly popular, wind tunnel models are yet again showing their potential to help engineers improve the lift-to-drag ratio (or L/D ratio) of these and many other aerospace components.

In this article, Dr Filomeno Martina, CEO and co-founder of WAAM3D, discusses how 3D metal printing is being used by aerospace research companies to improve their product development and innovation and how these prototypes are performing.

Reducing the cost of metal prototyping

The testing and developing of an aerospace part through prototype design can be a long, drawn-out, costly process. However, this stage is vital as the more effective the prototype, the better the finished product. As well as being used for advanced stage and pre-production phases, metal prototypes can also be used early on, particularly when mechanical and functional performance needs to be assessed. Metal prototypes can be made from aluminium, steel or other materials and created using a range of processes such as CNC machining, sheet metal forming, casting or 3D metal printing.

Wire Arc Additive Manufacturing (WAAM) is a 3D metal printing technique that has the potential to transform large-scale aerospace prototype and component production. This is because it avoids the expensive waste associated with machining materials such as titanium and can create less complex, medium-to-large scale structures in a range of materials (from titanium, aluminium, refractory metals, steel, bronze and copper to Invar, Inconel and magnesium). It is particularly suitable to build medium to large aircraft components such as cruciform, flanges, stiffened panels and wing ribs.

WAAM in practice

Over recent years, Aircraft Research Association Ltd (ARA), based in Bedford, UK has been looking into ways to improve lead times and costs for model creation. Having spent many years providing independent research and development to the UK aerospace industry, the company has a global customer base extending from the west coast of North America, across Europe, to the Far East of Asia. ARA is also recognized as a Centre of Excellence in Aerodynamics and having worked on many innovative projects for the worlds’ major commercial aircraft and defense system manufacturers, is used to pushing the design envelope for technical advantage.

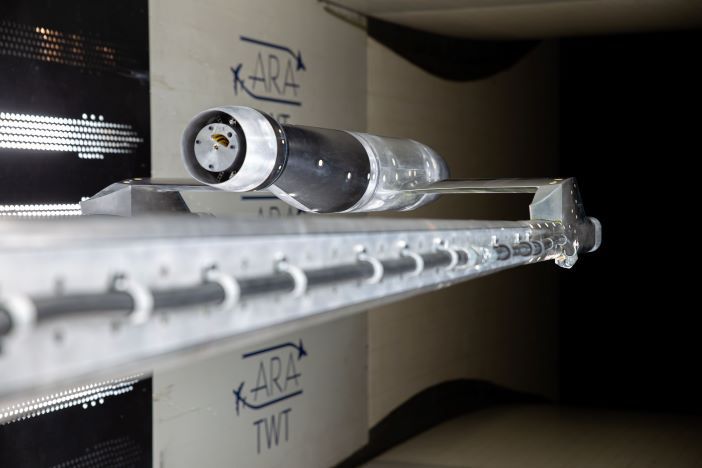

Having previously investigated the potential of a steel wing with the founders of WAAM3D and their team at Cranfield, the aerodynamics engineers at ARA knew that WAAM had the potential to reduce wind tunnel model lead times and costs. To test this theory, ARA chose a 190mm diameter and 350mm length aluminium nose cone to be produced using the WAAM process that could be integrated into a wind tunnel model as part of a Clean Sky 2 research and innovation funded programme (under GA Agreement no. 864803).

Optimizing the design for WAAM

Based on Cranfield University’s research carried out since 2006, WAAM3D is a leader in large-scale additive manufacturing. Having experience of delivering turnkey solutions based on in-house developed products, services, and materials, the team worked closely with ARA to optimize the design of the nose cone to ensure it delivered in terms of time and cost savings. To do this, the WAAM3D team considered the geometry and made sure that the majority of the starting bar feedstock was built around a vibration damper integrated within the nose cone. This minimized the deposited material, saving time, money, and materials.

Shape definition to manufactured component

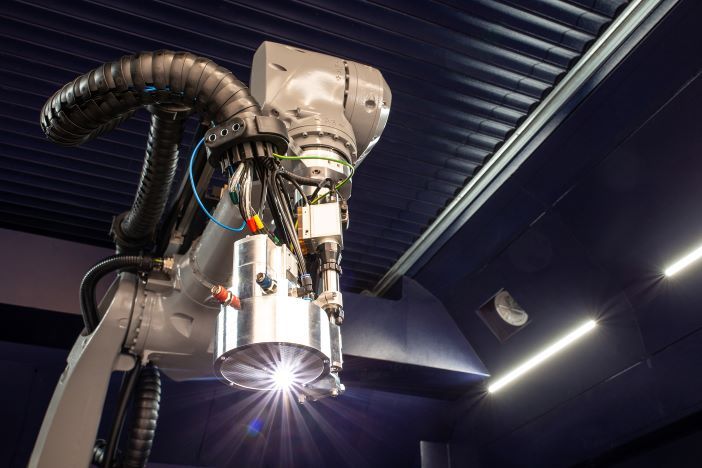

The nose cone was made from aluminium 2319 wire feedstock. The near-net shape was produced in WAAM3D’s large format 3D metal additive printing platform – RoboWAAM and was carefully monitored throughout the deposition process by ARA and WAAM3D.

Dr James Alderman, Principal Aerodynamics Engineer at ARA explains further: “We chose to produce a nose cone using WAAM, as we wanted a low risk way to investigate the WAAM technique: a nose cone is a relatively un-stressed part, with a safety factor of around 200. The aim was to see how the process performed in terms of timings, cost, and material savings and to subsequently decide if higher-stress components would benefit from this production process”.

“Once printed, the critical surfaces of the nose cone – those that would be wind swept or interfacing – underwent post machining and inspection at ARA. We set surface profile and finish tolerances of < +- 0.1mm and Ra < 0.8 microns respectively and these were achieved with ease. Also importantly, there were no issues with any distortion during the machining process.”

Fit for purpose

The two organisations, leveraging on decades of experience in their respective fields, were able to reduce material usage by 74% in the aluminium nose cone, which has significant environmental benefits for other projects moving forwards.

Regarding timings and cost, Dr James Alderman says: “This project was carried out so that we could learn about the process of designing for WAAM and how to post machine it, so we took our time with it. However, we believe that WAAM would deliver around 5-10% cost savings compared to machining from billet in aluminium and would be delivered more quickly now that the learning curve has been shortened.

“The nose cone produced using WAAM was a success, as it demonstrated the potential benefits of this technique for the manufacture of wind tunnel model components. I see WAAM as a way of shortening our lead times and costs and cutting material waste on other components in the future.”

The nose cone has been successfully integrated into a wind tunnel model that has been tested in ARA’s Transonic Wind Tunnel. This project demonstrates that prototypes can be developed quickly – and to defined tolerances – using WAAM and perform well under testing conditions.

Dr Filomeno Martina co-founded WAAM3D in July 2018 with a research team from Cranfield University, UK, where he was a senior lecturer and researcher. His achievements whilst in academia include coordinating a €1-million EU Erasmus project to set up at Cranfield University “the first ever MSc in Metal AM in the world.”

He has contributed to the writing and coordination of several successful multi-million-pound bids and projects. During his PhD and post-doc work, he achieved better than wrought properties with alloys of titanium, nickel and iron, with a now patented combination of AM and in-process cold work of the deposit.

He is a regular speaker on WAAM conferences globally and has over 40 peer-reviewed journal articles, some of which have been cited over 1,400 times. He has also helped draft ASTM and BSI standards on DED and WAAM. He was also given the prestigious International Outstanding Young Researcher in Freeform and Additive Manufacturing Award (FAME Jr) at the 2022 Solid Freeform Fabrication Symposium.