Military jet company Aeralis has won a £9 million (US$11 million) contract to provide digital engineering services to MOD.

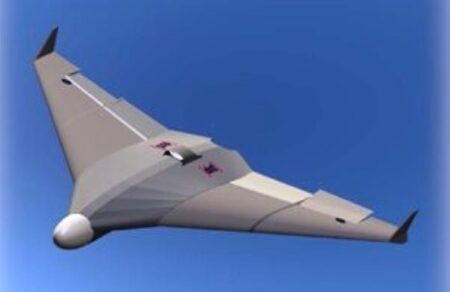

Aeralis was founded in 2015 and is developing a family of light military aircraft with a digital-first approach to design, development and design. Under the contract, the MOD will be able to access information that Aeralis generates using the company’s digital enterprise system.

Aeralis has developed the system to reduce the time and cost of developing its family of fighter jets.

The MOD said it will use the learning from Aeralis’ approach to reduce the cost and risk for other development programs including the UK’s Future Combat Air System, also known as Tempest.

This company has been working with the RAF’s Rapid Capabilities Office (RCO) to support Pyramid, the RAF’s Open Mission System Architecture (OMS) since February 2021. The Pyramid OMS is planned to form the core of the modular avionics and mission system Aeralis will use in its fighter jets.

There are now over 135 people involved in the development of Aeralis’ aircraft across 16 organizations in the UK. Aeralis said the new contract will create and sustain a further 250 jobs and many more in the supply chain.

Tristan Crawford, Aeralis’ founder and CEO said, “This MOD contract is another exciting step towards rejuvenating the UK’s sovereign ability to develop whole aircraft ready for the future.

“We are the only company in the UK taking this pioneering digital engineering approach as part of a new economic model that supports the development of more capable and ultimately affordable light military aircraft, marking an important milestone in the development of the first wholly British crewed aircraft since the 1970s.”

Aeralis’ “Digital Aviation Learning from Experience” contract is part of the MOD’s Global Combat Air Programme. Richard Berthon, director of future combat air for the MOD said, “I am delighted that the Future Combat Air System will benefit from the transformational digital engineering services of Aeralis. The learning that we will get from Aeralis will support digital engineering across our FCAS enterprise; providing us with the information we need to be able make informed decisions on this programme as it progresses.”

Digital-led engineering and development approaches are already being used elsewhere in the world in an effort to reduce time and costs for defense programs. Boeing and Saab this year rolled out the first production T-7A Red Hawk, which used digital engineering processes to reduce development and manufacturing time by around 80% compared to traditional processes.