Materials company Parker Chomerics has launched a new material that can protect drones from electromagnetic interference and overheating.

Choform 5575, Form-In-Place (FIP) is a moisture cured silver-plated aluminum filled silicone material offering up to 80 dB shielding effectiveness. The EMI gasket is robotically dispensed and can be directly applied onto the aluminum casting of a drone to act as a barrier, stopping the electrical circuits talking to each other and causing premature failure.

Drones operating near cell phone towers, buildings, antennae, high-voltage power lines and other obstacles can be affected by serious electromagnetic interference (EMI), compromising their performance and safety.

Another potential major challenge in drones is overheating, which can be caused by the high processing load on the drone’s electronics and the rotors.

Meeting these heat and EMI challenges requires shielding and thermal protection to protect the internal electronics from malfunctioning.

Most drones are also mass produced, so shielding solutions need to be deployed using automated methods to keep assembly costs down. Engineers also want solutions to be lightweight, weather resistant and allow communication with a controller on the ground.

Using an FIP gasket saves up to 60% of space and weight in the drone housing, as flanges can be as narrow as 0.025 in (0.76mm).

Choform 5575 has a high resistance to corrosion when dispensed onto aluminum, preventing galvanic corrosion in the electronic enclosure.

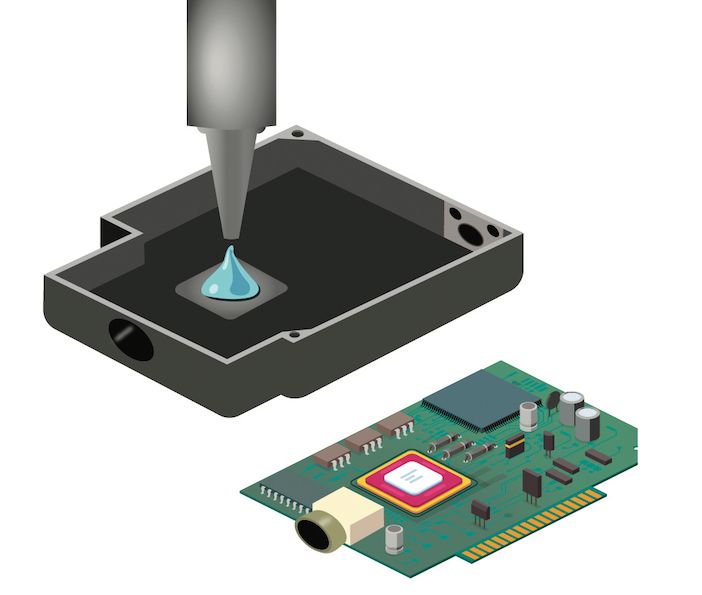

To mitigate thermal effects, Parker Chomerics has also developed the Therm-a-gap gel 37, which offers a 3.7 W/m-K thermal conductivity and can be used to conduct heat from the chipset to the drone’s enclosure.

This pre-cured, single component thermal gel material can be dispensed directly onto the chipset by automation, reducing production time. The gel has a soft, paste consistency, eliminating any stress on the electronic components and requires no mixing or curing.