Airbus has successfully tested a hydrogen fuel cell at 1.2MW, the level of power its engineers believe is needed for a fuel cell-based commercial passenger aircraft to fly.

The European aircraft manufacturer is developing the hydrogen fuel cell-based propulsion system as part of its ZeroE research program. ZeroE aims to develop three zero-emission aircraft that could enter service by 2035.

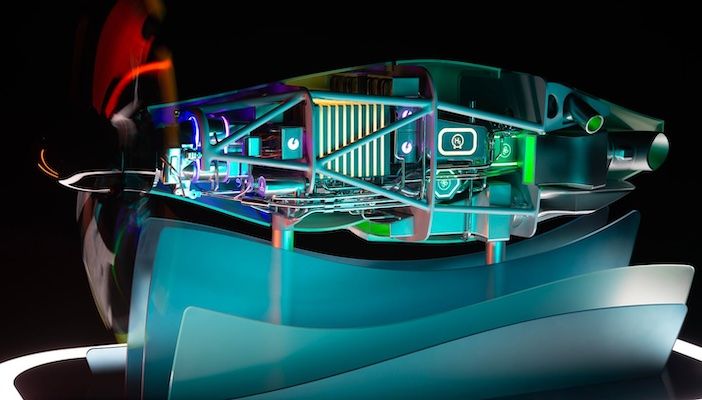

First revealed in December 2020, one of the ZeroE concepts is a 100 seat, 1,150 mile (1,850km) range aircraft that uses six hydrogen fuel cell powered engines.

According to Airbus, each of these fuel cell engines would need to output up to 1.2MW of electricity to make the concept viable, and this level of power was achieved during bench testing at its Ottobrunn facility near Munich in Germany earlier this year.

Speaking at the Paris Air Show this week, Sabine Klauke, chief technical officer of Airbus said, “This is the most powerful fuel cell test ever achieved in aviation, anywhere in the world and it will be a great platform for us to learn from.”

Glenn Lewellyn, Airbus’ vice president of ZeroE aircraft said, “This is a huge and unique achievement – a major step on our roadmap to a flight demonstration between 2026 and 2028.

“1.2MW is the power level required for a commercial aircraft application. This is a fully-electric propulsion system capable of producing the take-off power of a large commercial aircraft.”

Flight profiles and power levels examined

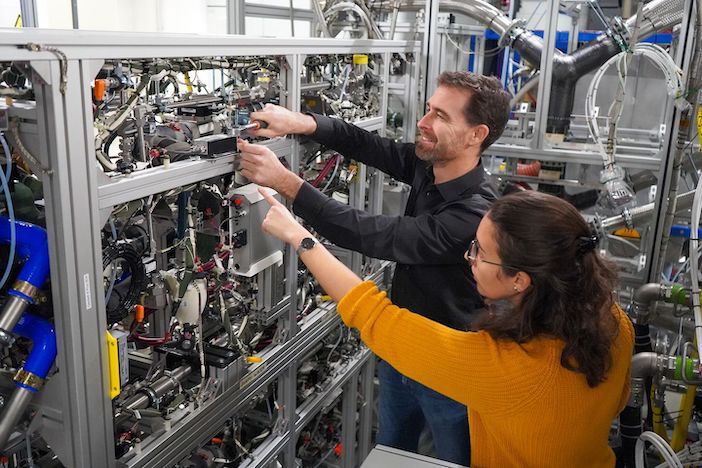

The fuel cell rig at Ottobrunn is being used to analyze power levels during different flight profiles. Earlier this month engineers recreated a full flight profile for the first time during testing, from engine power on, taxiing, takeoff, max power and cruise to descent.

The rig recreates representative loads on a propeller with both static and dynamic load changes going into the gearbox, but cannot represent the effects of altitude. “Our test capability also allows us to explore scenarios when components fail, and check that the system reconfigures itself in a way that allows continued safe operation and ultimately safe flight,” said Lewellyn.

“All of the data from the testing is feeding into the design, test and manufacturing of the engines and the final aircraft. It’s of massive value.”

The team will next conduct more ground testing of the fuel cell and begin work on the fuel cell propulsion system which will be flight tested on Airbus’ A380 testbed.

Engineering firm Liebherr produced the air supply system for the fuel cell in the test rig, German automotive supplier ElringKlinger the fuel cell through its AeroStack joint venture with Airbus, and Airbus Helicopters developed the gearbox.

Fuel cell to provide auxillary power

Meanwhile, Airbus has also started a project through its UpNext innovation unit that aims to fly a hydrogen fuel cell system onboard a modified-A330 to power its APU (auxiliary power unit) in 2025. The HyPower project will be run from Spain and is being partially funded by the Spanish Government.

The fuel cell, which will be based on the one being developed in Germany, would power non-propulsive systems such as air conditioning, lighting and avionics and could reduce the use of kerosene in an aircraft by up to 5%

“We want to test under realistic conditions, which means we will fly sorties of one hour up to 25,000ft, and take 10kg of gaseous hydrogen with us to demonstrate this power generation,” said Michael Augello, CEO of Airbus UpNext.