Researchers at GE Aerospace are to test a small engine that combines fuels cells with a gas turbine and runs off Sustainable Aviation Fuel.

The prototype engine could one day be scaled up and used in zero-emission commercial aircraft to give a much greater range than current battery-electric based propulsion systems allow.

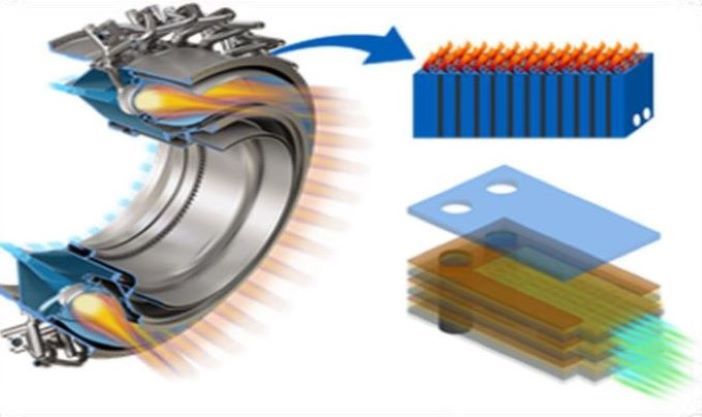

The hybrid propulsion system was designed as part of the US Government-funded FlyCLEEN (FueL CelL Embedded ENgine) project that started in 2021. It is a 25kW power generation subsystem that integrates solid oxide fuel cells with a Sustainable Aviation Fuel (SAF)-powered gas turbine.

The GE Aerospace research team was this month awarded a further US$4.5 million to build and test the propulsion system for the next phase of the project.

The novel hybrid approach uses SAF in both the fuel cells and gas turbines. A portion of SAF is reformed into Syngas to feed the fuel cells, while the rest of the SAF is consumed in the gas turbine engine.

The use of fuel cells could vastly improve the efficiency of converting the chemical energy from SAF into electric power and move closer to net zero CO2 emissions.

John Hong, a GE Aerospace senior combustion research engineer and FLyCLEEN project leader said, “The integration of fuel cells into jet engine propulsion system represents a potentially promising hybrid technology for additional fuel efficiency technologies in higher thrust aircraft applications.”

“The use of SAF demonstrates the compatibility with lower carbon fuels to capture further CO2 reduction benefits.”

https://www.tiktok.com/@worldofge/video/7237596327746489642

FlyCLEEN is being funded through APRA-E (Advanced Research Projects Agency–Energy). ARPA-E is running several research programs to advance the fundamental building blocks of commercial passenger hybrid electric flight. Other GE Aerospace and ARPA-E programs are looking at how to scale up the electric powertrain and the cabling required for hybrid electric propulsion

Hong added, “This is such an exciting time for the aerospace industry. From fuel cells and SAF to advances in electric power, hydrogen, and even new engine architectures like our open fan design, we are seeing a confluence of technologies driving progress on a number of fronts.

“We will need every bit of new investments and public partnerships like we have with ARPA-E to meet the industry’s goal of net zero CO2 emissions by 2050.”

GE Aerospace Research, which is based in the Niskayuna, New York in the USA and Bengaluru, India has more than 650 researchers and has also been working with France’s Safran on the CFM RISE (Revolutionary Innovation for Sustainable Engines) program, since 2021. RISE aims to deliver a 20% reduction in fuel consumption compared to current generation engines, through the use of hybrid-electric propulsion technologies, the use of hydrogen-fuel and 100% SAF, as well as its open fan design.