MDS is to supply the propulsion test bench for Airbus’s E-Fan X aircraft, a critical part of the program to develop the hybrid-electric demonstrator.

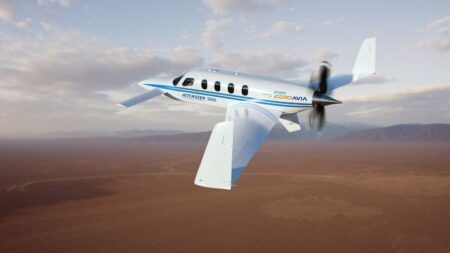

The E-Fan X, which is set to fly in 2020, is being developed by Airbus, Rolls-Royce and Siemens, with the aim of maturing hybrid-electric propulsion technology for commercial aviation.

Engineers from the companies are modifying a BAe 146 aircraft by replacing one of its four gas turbine engines with a 2MW electric motor.

The E-Fan X will be the first time an electric motor of its size is used to propel a passenger aircraft in flight tests. The propulsion system will be powered by a generator housed in the fuselage – MDS will be providing the test equipment and platform for testing this component.

The generator will be tested at Airbus’s E-Aircraft Systems (EAS) Test House in Ottobrunn near Munich in Germany, a 4,500m² (48,000ft²) facility currently under construction and due for completion in March 2019.

MDS is to install a 2.5MW ‘GenSet Test Bench’, consisting of a generator and AE2100 gas turbine engine, at the EAS Test House. MDS will be designing the test bench to the specific requirements of this Airbus initiative and managing the complete implementation phase from beginning to end.

Marcus Schulz, head of test and simulation for Airbus, said, “MDS has been selected as a preferred supplier for the GenSet Test Bench of the E-Fan X. We are convinced that this project will be a success thanks to MDS’s expertise and experience in propulsion test bench development.”

John Jastremski, president and CEO of MDS, said, “Hybrid-electric aircraft represent the next step in the evolution of air travel. We are excited to be selected by Airbus to be part of this innovative technology demonstrator program, bringing the world one step closer to being less reliant on fossil fuels.”

MDS added that it has a patent on an “ambitious green technology” that it plans to use in the “small-scale testing” of engines. An example of this is MDS’ Kinetic Energy Recovery (KER) system which places a turbine behind the engine in a test cell and converts the kinetic energy in the airflow into useful mechanical energy, which is then used to drive a generator. The generator converts this mechanical energy into useable electrical energy, while keeping the test cell aerodynamic integrity intact.

The E-Fan X demonstrator will examine issues around hybrid-electric propulsion systems such as thermal effects, electric thrust management, altitude and dynamic effects on electric systems and electromagnetic compatibility issues.

The program also aims at establishing the requirements for future certification of electrically powered aircraft while training a new generation of designers and engineers to bring hybrid-electric commercial aircraft one step closer to reality.

Read our in-depth profile of Airbus’ EAS Test House and other similar facilities, including NASA’s Electric Aircraft Testbed here.

Glenn Llewellyn, Airbus’ corporate technology office’s general manager for electrification is one of the speakers at the forthcoming Electric & Hybrid Aerospace Technology Symposium, the world’s leading international conference dedicated to ultra-low-emission aircraft technology and full-electric flight, which takes place on November 8-9 in Cologne, Germany.