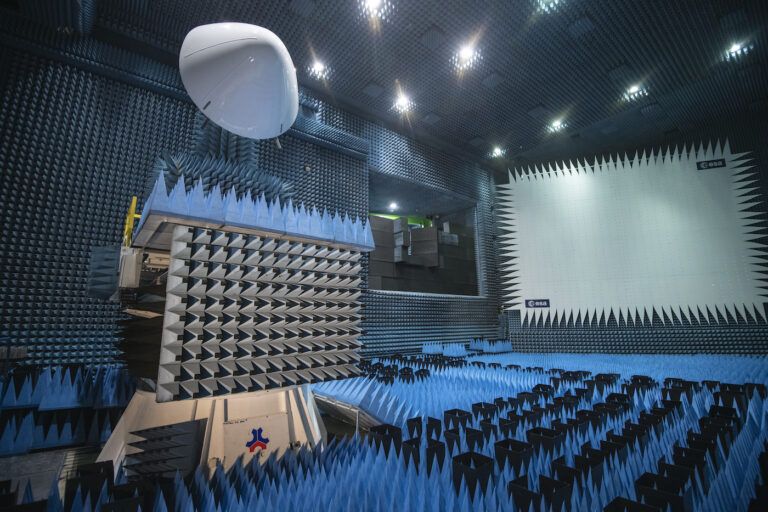

The European Space Agency’s Hertz Chamber usually used for the radio frequency testing of satellites, has been successfully used to test the performance of a repaired radome for an Airbus A340.

The recent test campaign in the Hertz chamber, which is part of the European Space Agency’s (ESA) ESTEC technical centre in Noordwijk, Holland, was carried out for Specto Aerospace in just a day.

The metal-walled Hybrid European Radio Frequency and Antenna Test Zone chamber is shut off from all external influences. Its internal walls are studded with radio-absorbing anechoic’ foam pyramids to enable radio-frequency (RF) testing without any distorting reflections.

The chamber is unusual in that it can assess radio signals from antennas either on a local near-field basis or as if the signal has crossed thousands of kilometres of space. This enables it to test a wider range of satellites and antenna systems.

ESA antenna engineer Eric Van Der Houwen said, “We had a rare gap in our test schedule and were able to accommodate a commercial customer.

“Specto works on repairing damaged structural aircraft parts like radomes on the noses of aircraft, which protect forward-looking weather radar and other equipment. Before any repaired radome can be returned to flight it needs RF testing to confirm that the repair has been a success and the structure is performing acceptably.”

A radome can be damaged by lightning strikes, bird strikes or hail erosion. The repair process returns the aramid fibre honeycomb composite sandwich structure to a high mechanically stiff and aerodynamically smooth state, while also ensuring the desired RF performance.

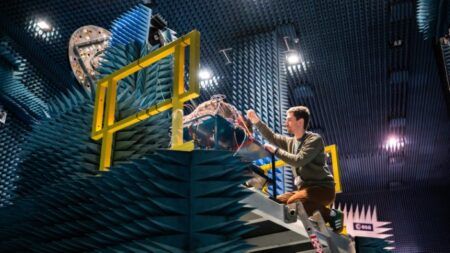

“Sometimes a repaired radome can look good but might not perform so well in RF terms,” said Van Der Houwen. “It might be that the structure is absorbing too much RF energy, or triggering signal reflections or interactions that alter the shape of what should be a forward-looking signal. In this particular case, this radome required a ‘side lobe level test’ – checking its sideways emissions.

“So, we first of all measured the antenna pattern and energy level without the radome and then with the radome to see how much these values change. Finally, we tested the antenna without the radome, to make sure our results match on a reliable basis.”

Jeroen Mast, managing director of Specto said, “ESA is one of our reliable partners for specific aircraft parts testing. Our in-house test facility is able to perform the standard transmission efficiency tests for aircraft radomes, with ESA’s anechoic test facilities offering a valuable add-on to our services.”