Supersonic aircraft developer Aerion has confirmed the progress it has made developing it AS2 business jet, which is on schedule for its first test flight in 2023 and revealed details about the airplane’s engine and avionics.

The AS2 is a 12-passenger business jet which will fly at a maximum speed of Mach 1.4 and is planned for certification and entry into service by 2025.

Nevada-based Aerion is working with Lockheed Martin, GE Aviation and Honeywell on the AS2 and has so far completed the conceptual design phase for the supersonic business jet. The more detailed preliminary design phase for the aircraft will be complete by June 2020, the company said this week.

Speaking at the National Business Aviation Asssocation’s annual conference in Orlando, Florida Aerion’s CEO Tom Vice said, “We’re on track to fly in 2023, and before that year is out cross the Atlantic at supersonic speed, which will be the first supersonic crossing since Concorde’s retirement 20 years earlier.

“We’ve overcome some huge technical hurdles and we’re confident we’ll meet Stage 5 takeoff and landing noise requirements. We’ve made strides in structures and systems. We’re recruiting top tier suppliers. And we’re attracting the best and brightest engineering talent to the program as we grow our organization.”

The more stringent Stage 5 Airplane Noise Standards were introduced in the USA for all new jet aircraft with a Maximum Takeoff Weight (MTOW) greater than or equal to 55,000 kg made after December 31, 2017. Aircraft with a a MTOW of less than 55,000 kg will need to adopt this standard by December 31, 2020. Stage 5 requires a cumulative reduction of 7 EPNdB (Effective Perceived Noise Level, in decibels)

Aerion has been working with Lockheed Martin since December 2017. The defence and aerospace company is providing support for the engineering, certification and production of the AS2.

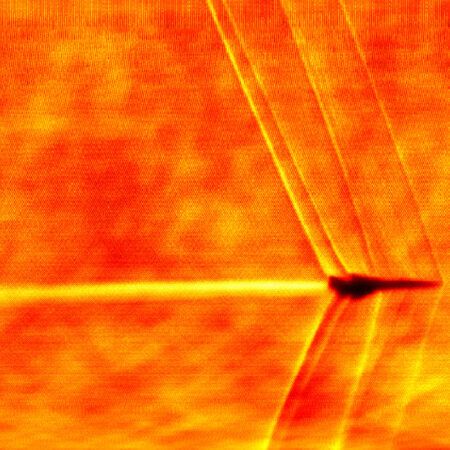

GE Aviation also released details and a video of the Affinity engine at the NBAA conference this week. The first civil supersonic engine to be developed in 55 years, the Affinity is a medium bypass ratio, twin-shaft, twin-fan turbofan engine controlled by a next generation Full Authority Digital Engine Control (FADEC).

The engine, which uses a core adapted from GE’s commercial airliner engines, has been designed to meet the Stage 5 subsonic noise requirements.

GE Aviation said that the twin-fans of the Affinity will provide the highest bypass ratio of any supersonic engine, that it has a non-augmented supersonic exhaust system which removes the need for an afterburner and a more durable combustor with advanced coatings for sustained high-speed operation.

The Affinity engine has been in development since 2015 and its final configuration was decided in May 2017. Detailed design and test article production for the engine is planned to begin in 2020.

Meanwhile, Honeywell has been selected to supply the cockpit and avionics for the AS2. Carl Esposito, president of Electronic Solutions at Honeywell said, “We will deliver a comprehensive connected aircraft solution that will enable operators to reach their destinations faster than ever before, maximizing their productivity while providing an exceptional travel experience.”

Vice from Aerion added, “The AS2 is the first step on a roadmap to making supersonic travel efficient, sustainable, and widely available. We are starting with a business jet because its where we see a viable market for the AS2. It will be our springboard to larger and faster designs, both for business aviation and commercial airliners.

“Today we are adapting off-the-shelf engine core technology. For the supersonic industry to progress we need to demonstrate the market and spur the development of new engine technologies that will meet evolving regulations for noise and emissions, while boosting speed.

“A next generation beyond the AS2, based on further adaptation of current engine technology, could take us from the AS2’s speed of Mach 1.4 to Mach 1.6, and could serve as a larger cabin, longer-range business jet and small airliner. Entirely new engine designs hold the potential to build larger aircraft able to fly at Mach 1.8 and above.

“This evolution will require considerable investment in new technology and will arrive in stages over the next several decades, and Aerion intends to be at the forefront of these developments.”