Aerojet Rocketdyne has successfully hot-fire tested a full-scale, additively manufactured thrust chamber assembly for the RL10 rocket engine that was built from a copper alloy using selective laser melting (SLM) technology, which is often referred to as 3D printing.

Aerojet Rocketdyne has been actively working over the last decade to incorporate 3D printing technology into the RL10 and other propulsion systems to make them more affordable while taking advantage of the inherent design and performance capabilities made possible by 3D printing. This recent testing was enabled by the Defense Production Act Title III program management office located at Wright-Patterson Air Force Base near Dayton, Ohio.

“Aerojet Rocketdyne has made several major upgrades to the RL10 to enhance the engine’s performance and affordability since it first entered service in the early 1960s,” said Aerojet Rocketdyne CEO and president, Eileen Drake. “Incorporating additive manufacturing into the RL10 is the next logical step as we look to make the engine even more affordable for our customers.”

“We believe this is the largest copper-alloy thrust chamber ever built with 3D printing and successfully tested,” said Additive Manufacturing Program manager Jeff Haynes.

“Producing aerospace-quality components with additive manufacturing is challenging. Producing them with a high-thermal-conductivity copper alloy using SLM technology is even more difficult. Infusing this technology into full-scale rocket engines is truly transformative as it opens up new design possibilities for our engineers and paves the way for a new generation of low-cost rocket engines.”

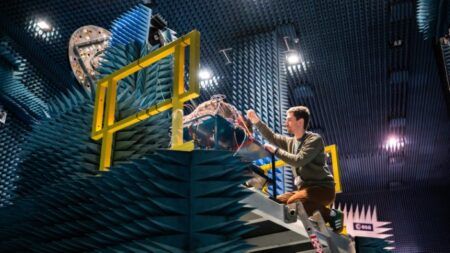

The 3D printed RL10 copper thrust chamber would replace the current RL10C-1 model design, which uses a very complex array of drawn, hydroformed stainless steel tubes that are brazed together to form a thrust chamber. The new chamber design is made up of only two primary copper parts and takes just under a month to print using SLM technology, reducing overall lead time by several months. The part-count reduction of greater than 90% is significant as it reduces complexity and cost when compared with RL10 thrust chambers that are built today using traditional manufacturing techniques.

Another key benefit provided by 3D printing is the ability to design and build advanced features that allow for improved heat transfer. For many rocket engine applications, this enhanced heat transfer capability enables a more compact and lighter engine, which is highly desirable in space launch applications.

“This full-scale RL10 thrust chamber test series further proves that additive manufacturing technology will enable us to continue to deliver high performance and reliability while substantially reducing component production costs,” said RL10 program director Christine Cooley.

“Now that we have validated our approach with full-scale testing of a 3D printed injector and copper thrust chamber, we are positioned to qualify a new generation of RL10 engines at a much lower cost, largely attributed to the additive manufacturing capabilities we have developed and demonstrated. With the next generation of RL10 engines, we aim to maintain the reliability and performance that our customers have come to expect, while at the same time making the engine more affordable to meet the demands of today’s marketplace.”

Aerojet Rocketdyne is applying 3D printing technology to many of its other products, including the RS-25 engines that will help explore deep space, and the company’s new AR1 booster engine that is being developed to replace Russian-built RD-180 engines by the congressionally-mandated deadline of 2019.

April 13, 2017