Supersonic airliner developer Boom is partnering with aerospace and defense company Kratos GE Additive and StandardAero on the propulsion system for its Overture aircraft.

The US-based Boom is developing the Mach 2.2-capable Overture to carry up to 80 passengers and have a range of 4,890 miles (7,870km) and will be powered by four engines.

Boom plans to roll out the first completed Overture aircraft in 2026, conduct the first flight the following year and has entry into service planned for 2029. Production of the first Overture aircraft is set to commence in 2024.

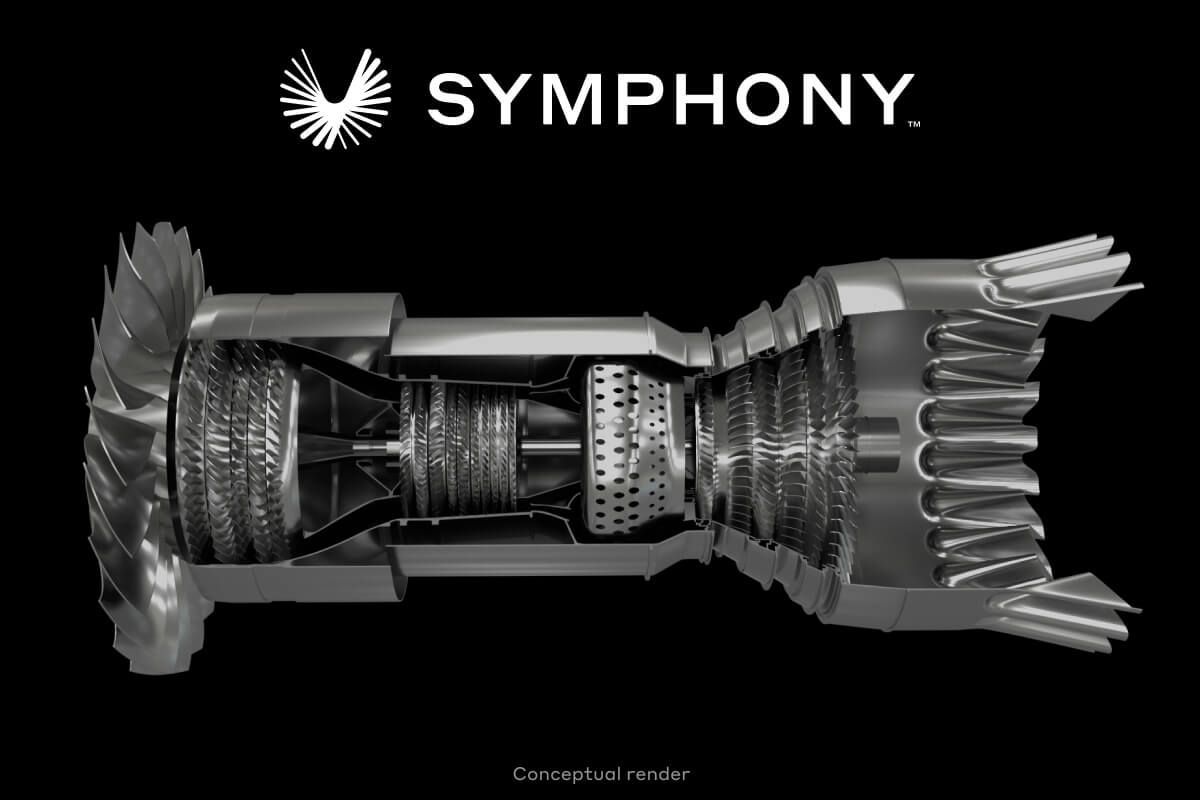

Overture’s propulsion system, called Symphony is being designe in partnership with Florida Turbine Technologies (FTT), which is part of Kratos. GE Additive is to provide additive technology design consulting, and StandardAero for maintenance.

Symphony will be a medium-bypass turbofan engine with the same basic engine architecture that currently powers all modern commercial aircraft. Unlike subsonic turbofans, this new propulsion system will include a Boom-designed axisymmetric supersonic intake, a variable-geometry low-noise exhaust nozzle, and a passively cooled high-pressure turbine.

“Developing a supersonic engine specifically for Overture offers by far the best value proposition for our customers,” said Blake Scholl, Founder and CEO of Boom Supersonic. “Through the Symphony program, we can provide our customers with an economically and environmentally sustainable supersonic airplane—a combination unattainable with the current constraints of derivative engines and industry norms.”

Symphony will be a bespoke design that uses existing technologies and materials to achieve supersonic performance and efficiency. Boom is also aiming for the propulsion system to operate at net zero carbon and meet Chapter 14 noise levels.

FTT’s supersonic engine design experience includes key engineers responsible for the design of the F-119 and F-135 supersonic engines that power the F-22 and F-35.

“The team at FTT has a decades-long history of developing innovative, high-performance propulsion solutions,” said Stacey Rock, President of Florida Turbine Technologies. “We are proud to team with Boom and its Symphony partners and look forward to developing the first bespoke engine for sustainable, economical supersonic flight.”

Symphony specification

- Architecture: twin-spool, medium-bypass turbofan engine, no afterburner

- Thrust: 35,000lbs at takeoff

- Fuel: optimized for 100% Sustainable Aviation Fuel

- Single-stage fan designed for quiet operation

- Passively cooled high-pressure turbine

- Additive manufacturing for low weight, low part count, and reduced assembly costs

- Certification: compliant with FAA and EASA Part 33 requirements