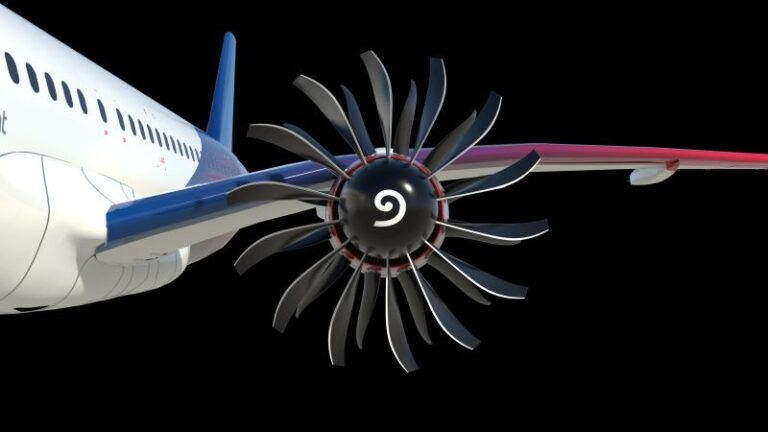

CFM International’s RISE open fan engine has completed a key wind tunnel testing program in France, while testing continues on core engine components in the USA.

The Revolutionary Innovation for Sustainable Engines (RISE) program was launched by CFM, a GE Aviation and Safran joint venture company in 2021, to develop an open fan engine, a compact engine core, and hybrid electric systems that are compatible with 100% SAF use.

CFM is targeting an aircraft CO2 emissions reduction of 20% compared to current generation engines with RISE, and wants to have the engine flying on single-aisle commercial jets by 2035. The company estimates that when combined with the use of SAF the technologies being developed for RISE could reduce aircraft emissions by up to 80%.

More than 2,000 GE and Safran engineers are now working on the program and more than 250 tests have now been completed for the project, CFM said.

More than 200 hours of wind tunnel testing were recently completed at the ONERA Aerospace Lab in France using a 1:5 scale model of the RISE Open Fan engine, including a version of the model mounted on a demonstrator plane wing section for testing with Airbus. A high-speed, low pressure turbine (LPT) test campaign with advanced turbine blades also ran.

Safran Aircraft Engines conducted the test campaign with French aerospace research agency ONERA to produce data on the aerodynamic and acoustic performance of open fan engine designs.

Pierre Cottenceau, executive vice president of engineering and research and technology for Safran Aircraft Engines said, “We have made significant progress in our testing plan, which confirms the benefits of the Open Fan propulsive system for the next generation of single-aisle aircraft.

“We completed key tests on fan acoustics, aerodynamics, and blade ingestion, and the high-speed, low-pressure turbine, while advancing hybrid electric tests for our suite of pioneering technologies.”

RISE program activity is also moving from component-level evaluations to more module-level tests.

GE Aerospace is working under a NASA contract to build and test a demonstrator engine core that includes new compressor, combustor, and high-pressure turbine (HPT) technologies as part of the RISE program.

Engineers at GE have so far conducted the first test run of next-generation HPT blades and nozzles using a demonstrator engine and started a second HPT airfoil endurance campaign.

Tests of next-generation compressor and combustion technologies have also started, which are looking to advance material capabilities and understanding of how new engine designs impact CO2, as well as non-CO2 emissions.

According to CFM durability is a key early focus of the RISE program.

“To change the future of flight and make it more sustainable, we have to change the aircraft engine,” said Mohamed Ali, senior vice president of engineering for GE Aerospace. “The open fan architecture is the most promising engine technology to help the industry reduce flight emissions, designed to meet or exceed customer expectations for durability and to deliver a step change in fuel efficiency using conventional or alternative jet fuels.”

To test airframer integration of the Open Fan architecture, plans have previously been announced with Airbus for an Open Fan flight technology demonstration.

Gael Meheust, president and CEO of CFM International said, “The work happening today on test rigs and with research partners around the world represents an unprecedented level of new technology development in CFM’s history.