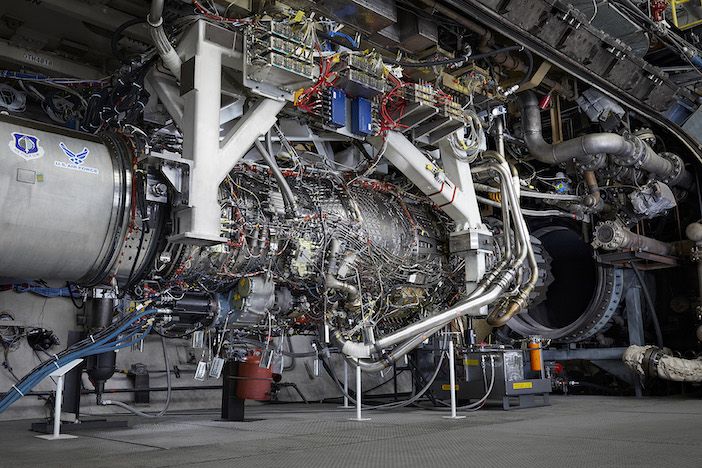

GE has completed testing its first XA100 variable cycle engine, which could be used by the F-35 and sixth generation fighter aircraft, after five months.

Completion of the full-scale prototype testing at GE Aviation’s Evendale, Ohio, altitude test facility is a significant milestone for the XA100 engine, technology development for which began 14 years ago.

Assembly of the second prototype XA100 engine is also underway, with testing on that engine expected to begin later this year.

David Tweedie, GE Edison Works’ general manager for advanced combat engines said, “We were exceptionally pleased with how the engine performed throughout the test. Bringing a new centerline fighter engine to test for the first time is a challenging endeavor, and this success is a testament to the great team that worked so hard to get us here.”

“This was the most heavily instrumented engine test in both GE and US Air Force history. We were able to obtain an immense amount of high-quality test data proving out the engine’s capabilities and demonstrating a good return on the Air Force’s investment.”

The testing found that the engine’s performance and mechanical behavior were consistent with pre-test predictions and met the requirements of the US Air Force’s development program.

As a variable cycle engine, also known as an adaptive cycle engine, the XA100 engine is designed to power flight at different subsonic, transonic, and supersonic speeds more efficiently than conventional engines can by changing the way it works.

The XA100 does this through a third-stream design that directs air to increase fuel efficiency and cooling or to the core and fan streams to provide additional thrust and performance. This enables the engine to provide a high-thrust mode for maximum power and a high-efficiency mode for optimum fuel savings and loiter time.

The engine’s components also use advanced materials such as ceramic matrix composites (CMC) and polymer matrix composites (PMC), for heat resistance and improved performance.

Compared to its predecessor, the XA100 engine provides 10% more thrust and improves fuel efficiency by 25%, as well as featuring more aircraft heat dissipation capacity within the same physical envelope as current propulsion systems.