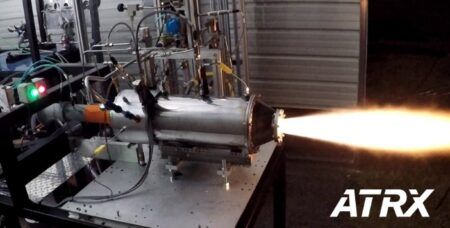

GE’s ATP / Catalyst engine is prepared for testing

GE Aviation has renamed its Advanced Turboprop engine the Catalyst.

The new name signifies GE’s attempt to develop the turboprop market through innovation, the company said, and is the first entirely new clean-sheet engine for the business and general aviation market in more than 30 years.

Paul Corkery, general manager for GE Aviation Turboprops, said, “The Catalyst engine is redefining what a turboprop can do for pilots, airframers and operators in business and general aviation.

“It acts as a catalyst in an industry segment that has seen very little technology infusion in decades.”

GE engineers have completed four design iterations and initiated a full preliminary design of the engine.

Textron is to use the Catalyst in its new Cessna Denali aircraft, with the maiden flight scheduled for before the end of this year.

The engine is being developed, tested and produced at a new GE facility in Prague, Czech Republic. When complete and at full production rate, this new facility is expected to have 500 additional employees.

The Catalyst was run for the first time at the Prague site in December 2017. Certification test are now taking place, with entry into service targeted for 2020, by which time the engine will have completed more than 2,000 hours of testing.

The Catalyst is the first turboprop engine in its class to introduce two stages of variable stator vanes and cooled high-pressure turbine blades. According to GE, it performs at a 16:1 overall pressure ratio, enabling the engine to achieve as much as 20% lower fuel burn and 10% higher cruise power compared to competitor offerings in the same size class.

The engine also uses 12 additively manufactured parts, which have taken the place of 855 conventionally manufactured parts and reduced the engine’s weight by 5%.

March 9, 2018