The UK has opened its new £4 million (US$5.5 million) National Space Propulsion Facility for testing large rocket engines with more sustainable propellants.

The National Space Propulsion Facility (NSPF) at the Westcott Space Cluster, Buckinghamshire can fire and test rocket engines at up to 1.3kN in high-altitude vacuum, an equivalent test altitude of 140,000ft.

The facility is the largest in the UK and one of only three of its type in the world. Around 60 people will be employed at the NSPF, which features the capability to test new types of more sustainable propellants, such as hydrogen peroxide and liquid oxygen.

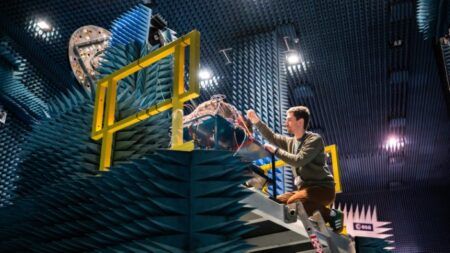

The European Space Agency (ESA) oversaw the design, assembly and commissioning of the facility – which is equipped to test-fire the most powerful classes of rocket engines used by spacecraft, working with the UK Space Agency and Nammo UK, which will operate the facility.

Mark Ford, Head of ESA’s Propulsion Engineering section said, “The new facility’s thruster test cell can perform test-firings of the largest class of satellite engines, delivering up to 1,300 Newtons of thrust.

“It will serve as the gold standard for testing of the biggest, mission-enabling thrusters to come, including the new ESA-supported High Thrust Apogee Engine, designed for future exploration missions, as well as numerous commercial projects.”

The facility’s thruster test cell possesses three modes of operation: equivalent sea level pressure, medium 20 km altitude equivalent pressure and high altitude of around 40 km height equivalent pressure.

The test cell simulates space by using powerful mechanical pumps that operate continuously to maintain its vacuum conditions down to 1.5 milliBar. They also remove the hot, supersonic exhaust plume from the rocket engine after it is diffused and cooled. This prevents it venting into the surrounding atmosphere in a noisy, explosive manner.

A high-performance heat exchanger is used to rapidly reduce the temperature of these gases down from 2000°C down to 50°C. Supplied by Reaction Engines, this heat exchanger represents an early industrial technology spin-off from the SABRE air-breathing rocket engine, which is being developed at test site elsewhere at Westcott.

Rob Selby, vice president of Nammo Space said, “Thanks to this key UK government investment, UK space can now compete favourably with the very best rocket test facilities in the world.

“This hot-fire test facility is already driving further growth in UK based spacecraft propulsion businesses. We look forward to testing engines for customers from all over the globe and to further key developments that the NSPTF will enable.”

Nigel MacKenzie, Westcott development manager said, “This is yet another leap forward for the development of Westcott in Buckinghamshire as a centre of excellence in the space propulsion and associated high-tech industries.

“Future Investment will ensure Westcott’s place at the heart of the UK space industry. Over the next 10 years, Westcott will become the UK Centre for the next generation of propulsion systems and small satellite manufacture.”