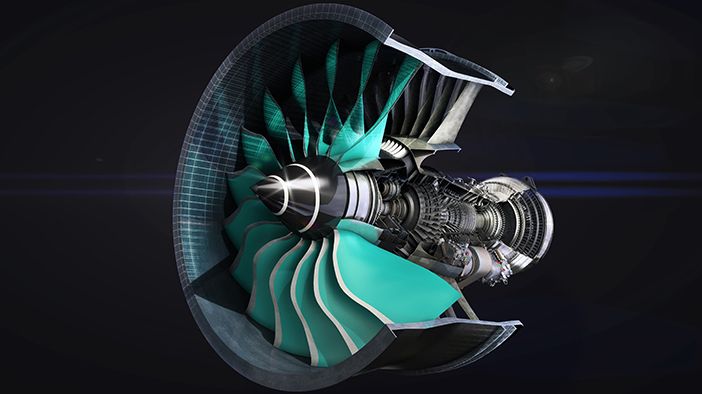

Artist’s Impression of the UltraFan engine (Image: Rolls-Royce)

Rolls-Royce is to flight test its next generation UltraFan engine with Airbus after the two companies signed an “integration collaboration agreement”.

The tests, which will demonstrate how the UltraFan engine can be integrated with aircraft, will be co-funded by the EU’s Clean Sky 2 program.

The agreement between Rolls-Royce and Airbus provides for nacelle and engine/aircraft integration architecture and technology enabler tests. Flights will be carried out on a Rolls-Royce flying testbed.

The integration phase of the program conducted with Airbus is an important part of achieving the overall fuel efficiency improvements the UltraFan higher bypass ratio engine, said Rolls-Royce.

Andy Geer, chief engineer and head of programme for UltraFan at Rolls-Royce said, “It is great to have Airbus expertise to further strengthen our ability to deliver this important development program. We remain very grateful to Clean Sky 2 for its continued recognition of the environmental benefits that UltraFan will bring.”

UltraFan uses new engine core architecture and a lean-burn combustion system to improve fuel burn efficiency and lower emissions, along with a carbon titanium fan blade system and composite casing to reduce weight. The engine also introduces a geared design to deliver efficient power at high-bypass ratios.

According to Rolls-Royce, the UltraFan engine design can be used on either widebody or narrowbody aircraft, and offers a 25% fuel efficiency improvement over the first-generation Trent engine.

Rolls-Royce engineers began testing UltraFan’s lean-burn combustion process, called ALECSys (Advanced Low Emissions Combustion System), for the first time on a test engine in Derby in the UK, in February. Tests on UltraFan’s gearbox started during September 2017 at the Rolls-Royce facility in Dahlewitz, near Berlin, Germany.

April 30, 2018