Researchers from Queen’s University Belfast have developed a new system to prevent ice from building up on aircraft.

Conventional anti-icing systems on most passenger aircraft are based on hot air which is bled from the engines and piped to the inner surface of the wing. The heat is then transferred to the outer surface by thermal conduction to stops ice from building up.

This method adds weight, requires maintenance and uses large amounts of energy, particularly on the new generation of composite aircraft.

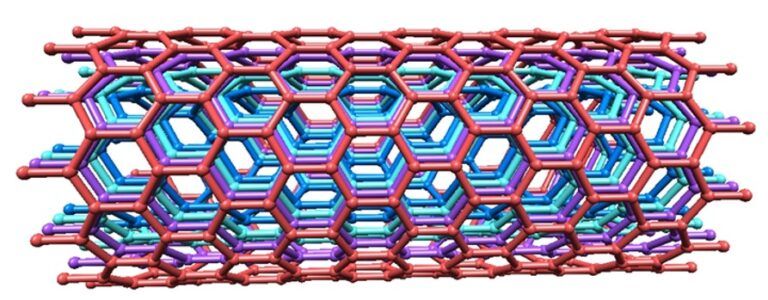

Researchers from Queen’s have developed an ultra-light weight heater from webs of carbon nanotubes (CNT) for de-icing aircraft surfaces.

Professor Brian Falzon, from the School of Mechanical and Aerospace Engineering, who led the research team said, “We started by creating a CNT web, where individual CNTs are aligned in the draw direction, and horizontally stacking 10-40 layers of the webs, at different orientations, to achieve the desired heating characteristics.

“Each layer of CNT web can be as thin as 1/2000 the thickness of a human hair and the weight of a web large enough to cover a football field would be less than 30 sheets of A4 photocopy paper.

“These CNT webs were cured within a thin glass fibre laminate to provide structural support, and connected to a power supply. When we carried out testing, we discovered that the newly developed CNT heaters achieved rapid heating which shows they could quickly de-ice aircraft and provide effective ice protection in flight.”

The nanotube anti-icing system is still in the early stages of development – TRL 3. Moving this from the lab to a product will require further investment from an interested industrial partner.

Falzon said, The webs could be attached on the inner surface of a wing leading edge, nacelle lipskin or could also be incorporated within a composite material.

“Incorporating such systems in a wing leading edge or nacelle lipskin will require developing a means of introducing electrical power into the system and optimisation of the CNT-web for the desired thermal performance – using the webs themselves as sensors to activate device.”

Dr Xudan Yao, a researcher on the project said, “Compared with the heating systems currently used on aircraft, the CNT heater that we have created is lighter, provides rapid and more uniform heating and is more energy efficient. It is also more flexible in terms of fitting the shape and performance of any surface or power requirement to achieve rapid anti-icing and de-icing.

The research was recently published in the journal Carbon.