Researchers in the USA are testing a thin heatshield built from carbon nanotubes that could be used in supersonic and hypersonic aircraft.

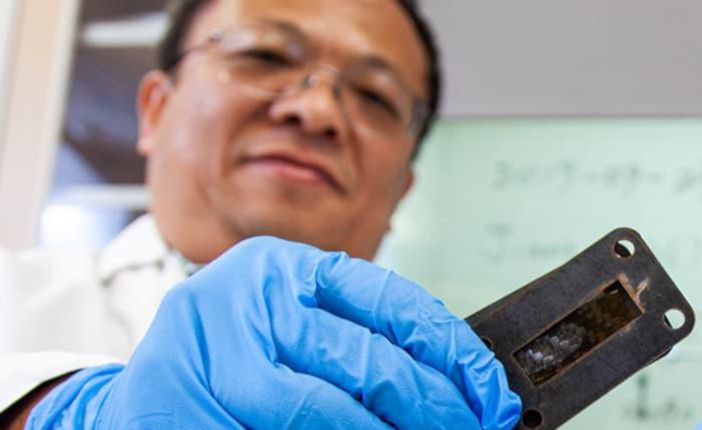

A research team at FAMU-FSU College of Engineering working at Florida State University’s High-Performance Materials Institute (HPMI) has used carbon nanotubes, linked hexagons of carbon atoms in the shape of a cylinder, to build heat shields. The sheets of nanotubes, also known as “buckypaper,” were soaked in a resin made of a compound called phenol, enabling the researchers to create a lightweight, flexible material that is also durable enough to potentially protect the body of a rocket or jet from the intense heat it faces while flying.

The research, which is being published in the November edition of CARBON involved building heat shields of different thicknesses and applying various tests, such as applying a flame to see how they prevented heat from reaching the carbon fiber layer they were meant to protect. Researchers also bent the samples to assess their strength after heating.

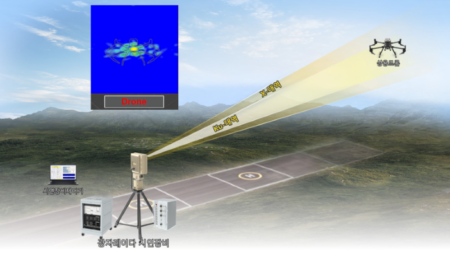

“Right now, our flight systems are becoming more and more high-speed, even going into hypersonic systems, which are five times the speed of sound,” said Professor Richard Liang, director of the HPMI. “When you have speeds that high, there’s more heat on a surface. Therefore, we need a much better thermal protection system.”

They found the samples with sheets of buckypaper were better than control samples at dispersing heat and keeping it from reaching the base layer. They also stayed strong and flexible compared to control samples made without protective layers of nanotubes.

The flexibility meant the nanotubes are less vulnerable to cracking at high temperatures compared to ceramics, a typical heat shield material. The carbon nanotubes are also lighter weight than ceramics, suiting them to use in aerospace as a heatshield.