The first COMAC C919, powered by CFM International’s advanced LEAP-1C integrated propulsion system, successfully completed a 79-minute first flight on May 5, marking the launch of the certification flight test program for the 150-passenger aircraft.

“This is a great day for all of us,” said He Dongfeng, COMAC president. “We are very happy with the LEAP-1C engine and have been pleased to work with CFM on this program. The engines performed beautifully during today’s flight and we believe they will bring our customers the levels of fuel efficiency and reliability they will require in their daily operations.”

“This is an epic moment,” said Gaël Méheust, president and CEO of CFM International. “On behalf of everyone at CFM, I extend our warmest congratulations to everyone at COMAC on achieving this great milestone. Our relationship with the aviation industry in China goes back more than 30 years and it is an honor to be part of the COMAC team as it launches the next exciting era in the country’s aviation history.”

To date, more than 5,000 CFM engines have been ordered/committed in China, including orders for more than 1,000 LEAP-1C integrated propulsion systems. The LEAP-1C integrated propulsion system was simultaneously awarded Type Certificates by both the European Aviation Safety Agency (EASA) and the US Federal Aviation Administration (FAA) in December 2016. Since then, COMAC has performed a series of ground tests, including low-speed and high-speed taxi tests leading up to today’s flight.

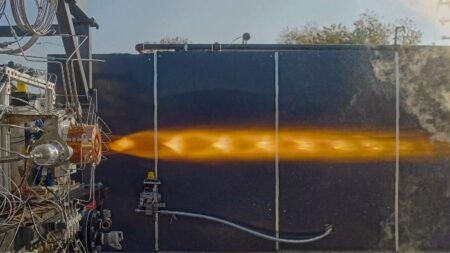

The LEAP engine was officially launched in December 2009 when COMAC selected the LEAP-1C as the sole Western powerplant for its 150-passenger C919 airplane. The engine incorporates a unique fully-integrated propulsion system (IPS), which includes the engine, nacelle, and thrust reverser. The IPS, along with the pylon developed by COMAC, were designed in conjunction with each other, resulting in improved aerodynamics, lower weight, and easier maintenance.

The LEAP-1C’s composite O-Duct thrust reverser was developed by Nexcelle, with its unique one-piece configuration contributing to a reduced overall structural weight and larger acoustic treatment surface.

In addition to the IPS, the LEAP-1C engine features some of the industry’s most advanced technologies, including 3-D woven carbon fiber composite fan blades and fan case; a unique debris rejection system; fourth generation three-dimensional aerodynamic designs; the Twin-Annular, Pre-Swirl (TAPS) combustor featuring additively manufactured fuel nozzles; ceramics matrix composite shrouds in the high-pressure turbine; and titanium aluminide (Ti-Al) blades in the low-pressure turbine.

The LEAP engine entered commercial service in August 2016 and is currently in operation with more than 10 airlines worldwide. The engines are providing operators with a 15% improvement in fuel efficiency and CO₂ emissions compared to today’s best CFM engine, along with dramatic reductions in engine noise and exhaust gaseous emissions. All this technology is bringing with it CFM’s legendary reliability and low maintenance costs.

May 10, 2017