Aircraft development firm Stratos has flown the latest prototype of its six-seat 716X jet aircraft for the first time.

The Redmond, Oregon-based company plans to offer the Stratos 716X as an experimental kit build aircraft, while the 716 will be certified by the FAA for production. Stratos defines the 716X as a “multi-role” VLJ (very light jet) designed to seat six people to support personal, business, and air taxi use.

The first flight, which was conducted by test pilot Sean VanHatten lasted 22 minutes and included a full power takeoff and a climb to 13,500 ft. A series of maneuvers was conducted to evaluate handling characteristics. The flight is the first of an extensive flight test program that will span the next several months.

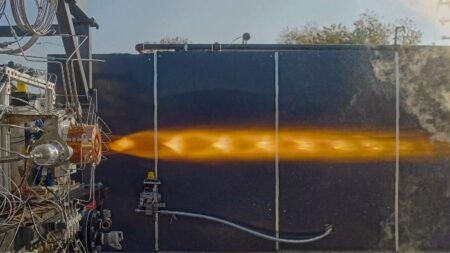

The Stratos 716X is powered by a single Pratt & Whitney JT15D-5 turbofan engine and features an all-carbon airframe. Designed to cruise at 400 knots, the aircraft features trailing link gear, is configured with dual G3X screens, GTN 750 MFD, has integrated Garmin Autopilot, dual standby attitude indicators, custom switch panels, a fully automated pressurization system, and air conditioning.

“The first flight of the 716X went as briefed, which is a testament to the design quality and the professionalism of the crew here at Stratos,” said VanHatten, “The aircraft is well harmonized, and its directional stability was very good. The Stratos Aircraft team should be very proud of this accomplishment, and I’m looking forward to continued flight testing of this new design.”

Stratos CTO, Carsten Sundin said, “The aircraft performed just as predicted and the initial feedback is that the handling qualities are excellent. We look forward to now expanding the flight envelope and demonstrating the aircraft’s full potential.

“We see producing a limited number of kit aircraft as a logical step towards certification. It will allow customers who don’t want to wait for the 716 certification an opportunity to own and operate a Stratos 716X much sooner, while we continue to develop our production processes.”

VanHatten has performed nineteen first flights and flown four prototype aircraft so far during development and testing of the aircraft.

“We have just commissioned our composite manufacturing facility. Advanced technology is applied in the construction of the carbon‑fiber parts, including a CNC ply cutter and laser projectors to aid the alignment of the individual plies. The dedicated building also has a large ‘walk‑in’ oven in which the completed parts are cured.” added Sundin.