Through its Aeronautical Product Development Technologies program (APDT), the National Research Council Canada (NRC) has shortened the time-to-market for new aeronautical products by three months. To achieve this goal, the NRC relied on 16 enhanced testing technologies to accelerate the certification process, including the NRC’s world-class wind tunnel and flight testing, structural testing and engine testing facilities.

“Aerospace companies are faced with unprecedented global competition to deliver new products to market on time, yet evaluating and refining a particularly innovative product can take longer than ever as certification requirements imposed by airworthiness authorities get stricter,” says Jerzy Komorowski, general manager, aerospace at the NRC.

“To help ease this pressure, the NRC develops solutions for the aerospace industry at the post-launch stage of aeronautical product development, recognizing that certification requirements are more expensive than in any other industry.”

To date, through the APDT program, the NRC has served 43 Canadian and international clients, and certified more than 24 newly developed products. With the recent addition of prototyping to its service offerings to address technology demonstrators, new fuels certification, additive manufacturing certification of secondary parts, hybrid propulsion and systems integration, the NRC is now in a position to help even more clients move more quickly through the aircraft product certification process.

To ensure it aligns with industry needs, the APTD program takes its strategic direction from an industry-led advisory board made up of the national airworthiness regulator Transport Canada and six major aerospace companies: Bombardier Aerospace, Bell Helicopter, CAE, Héroux-Devtek, Pratt & Whitney Canada, and Siemens Canada.

The APDT program’s aerodynamics team developed a mono-strut mount for aircraft models tested in the NRC’s 2×3m wind tunnel. The mono-strut employs an active model damping system, reducing model vibrations, especially near stall to decrease measurement uncertainty. Compared with the NRC’s traditional triple-strut mount, the mono-strut provides more accurate measurements of the forces acting on the model, and reduces the time required to complete a wind tunnel test campaign.

The flight test group advanced a technology that aids Canadians in peril. When asked to help develop simulators for helicopters to be used for search and rescue training, the NRC airworthiness and flight test engineers came up with a breakthrough plug-and-play instrumentation design, which was used to collect helicopter mission training flight test data.

This data in turn was used to accelerate the development of new mission training technologies and bring them to market more rapidly. The NRC pilots then performed flight tests that supported the development of the client’s leading mission training ‘roll-on, roll-off’ simulator, ultimately helping train pilots faster for some of the harshest environments encountered in Canadian search and rescue.

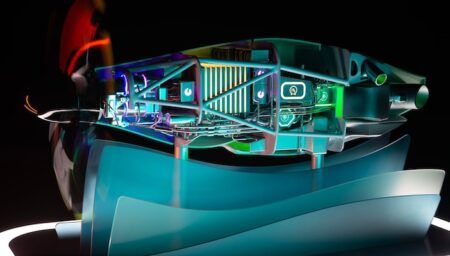

The propulsion team found a technical solution that lowered the cost of testing for level of emissions while increasing engine power. After building a specific combustor rig, NRC engineers devised a way to evaluate one sector of the combustor and make the results generalizable to the whole engine. This can save clients valuable testing time, getting their emission-friendly product to market faster.

When Bombardier added a winglet to its design as part of upgrades to their Challenger 300 business jet, the APDT program’s structures group was called in to do the structural test of the new airplane wing configuration. Using the NRC’s complement of structural test capabilities, the team was able to prove that the winglet could sustain the required flight loads, enabling the jet to receive Transport Canada clearance for flight testing. Once the loads were verified through flight testing, the NRC completed the certification test, and submitted the data and documentation to Transport Canada to grant structural certification.

June 21, 2017