Testing services provider Element has invested US$5m in an electromagnetic sled, which has the highest level of accuracy, repeatability and efficiency when compared to any other sled system currently available on the market.

The investment in the sled will help Element Warren become a center of excellence for seat structure and seat materials validation, said the company.

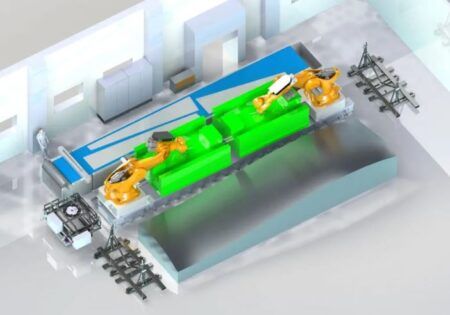

Based in the Element Warren laboratory, Michigan, the sled system has a number of features that reduces turnaround times for tests.

It uses an electrical energy storage system rather than a traditional pneumatic system, reducing regeneration times from 30 minutes to just 30 seconds between shots.

The enhanced accuracy of its electric system removes the need to repeat calibration shots and, in the majority of cases, pulse matching is still within 5% of target or less.

An independent E Liner camera system is also being used in conjunction with the sled, allowing for automated positioning of six cameras and the elimination of unwanted camera motion associated with traditional outriggers.

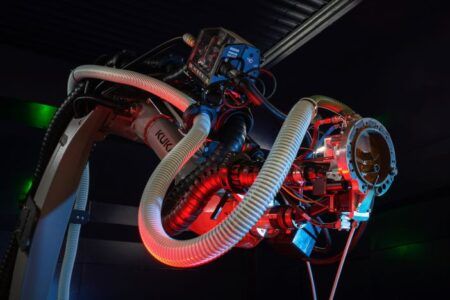

John Nelson, executive vice president of transportation and industrials, said, “From the latest high-speed cameras to the dummy positioning system, every component that has gone into this sled system is an example of the latest available technology known to the market. Our capabilities now extend to include the only electromagnetic sled of its kind in North America – there are only two others in existence in the world.

“This significant extension of our capabilities is a clear demonstration of our commitment to our customers in the transportation sector, ensuring that they benefit from the significant increase in efficiency, repeatability and accuracy of this new system.”