Element Materials Technology’s recently-opened testing laboratory in Shanghai, China has achieved General Electric’s GE S400 accreditation.

The 30,000 square foot facility, which was opened in October 2019, provides testing of both metallic and non-metallic materials for the aerospace sector.

GE S400 accreditation is awarded following an audit process to GE Aviation suppliers. The audit process is designed to ensure suppliers adopt rigorous requirements and confirms that the laboratory is working to the highest specified standard on metallurgical evaluations, mechanical testing and related specimen machining, said the company.

Element Shanghai has also gained ISO/IEC 17025:2017 Nadcap, A2LA and a range of other OEM approvals.

Rick Sluiters, executive vice president for Aerospace at Element said, “Since opening last year, our new laboratory in Shanghai has acquired accreditation and approvals that confirm its place as a leading provider to the aerospace and manufacturing industries in China and beyond.

“The laboratory offers local access to experts and equipment, saving customers time and money. The access to Element’s global network of technical capability, capacity and expertise brings additional benefits to working with the team in Shanghai.

“The investment in our laboratory has been in direct response to customer demand for destructive testing services on metals and composite materials as the region experiences considerable growth in our core sectors. This latest certification highlights that our team in Shanghai consistently delivers the highest standards of testing.”

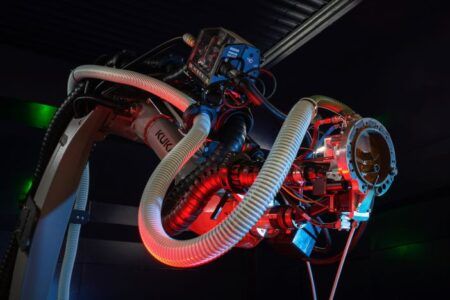

The Element Shanghai laboratory has a machine shop equipped for specimen preparation and can deliver a range of services including chemical analysis, mechanical testing, fatigue testing, metallurgical analysis, failure investigation and on-site testing. It also has a number of heat furnaces for the heat treatment of materials prior to testing.