GKN Aerospace has manufactured the first demonstrator wing components for Airbus’ “Wing of tomorrow” research program.

The multi-million project, which started in 2015, is aiming to investigate new materials, manufacturing and assembly techniques as well as new technologies in aerodynamics and wing architecture. The R&D work is being conducted at the Airbus Wing Integration Centre in Bristol, UK in partnership with the Aerospace Technology Institute (ATI).

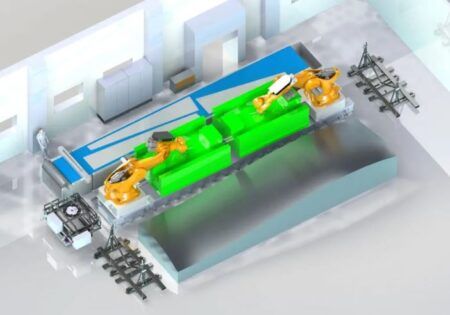

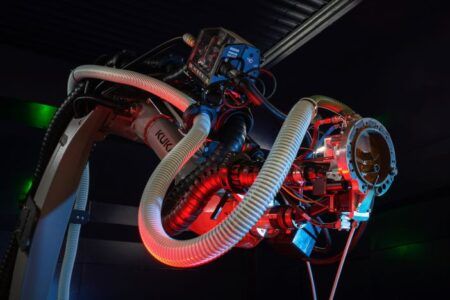

GKN is developing composite assembly automation technologies for wing structures as part of the program, with the aim of improving the productivity of the composite manufacturing processes and potentially reduce the weight of large commercial aircraft by up to 20%.

The composite parts manufactured for the project are samples of a section of the wing spar.

John Pritchard, CEO of aerostructures and systems Europe and Asia, GKN Aerospace said, “The manufacturing of the first composite demonstrators under the WoT program is a true milestone. The demand for lighter, stronger and low maintenance composite wing structures fits our sustainability goals.”

The company manufactures the A380’s fixed trailing edge and the wing leading edges for A380, A330 and A400M. For the A350 XWB GKN Aerospace developed and now supplies the 27m long rear wing spar and the inboard and outboard flaps, including skins, spars, ribs and leading edges.