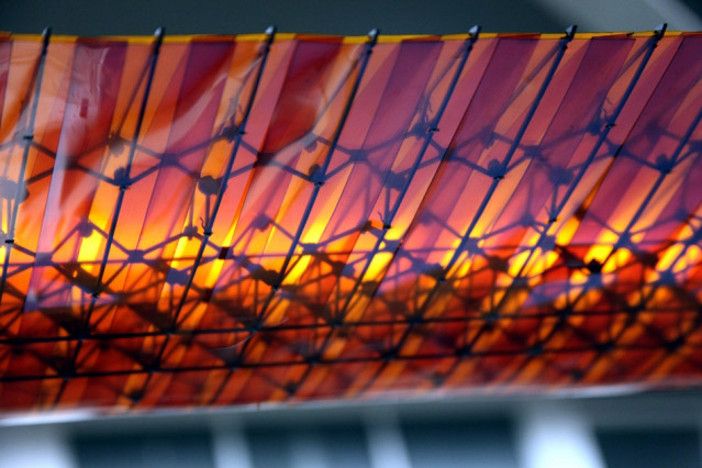

A new wing architecture, which could greatly simplify the manufacturing process and reduce fuel consumption by improving the wing’s aerodynamics and improving its agility, has been developed by engineers at MIT and NASA. It is based on a system of tiny, lightweight subunits that could be assembled by a team of small specialized robots, and ultimately could be used to build the entire airframe. The wing would be covered by a ‘skin’ made of overlapping pieces that might resemble scales or feathers.

Researchers have been trying for many years to achieve a reliable way of deforming wings as a substitute for the conventional, separate, moving surfaces, but all those efforts “have had little practical impact,” said Neil Gershenfeld, director of MIT’s Center for Bits and Atoms (CBA). The biggest problem was that most of these attempts relied on deforming the wing through the use of mechanical control structures within the wing, but these structures tended to be so heavy that they canceled out any efficiency advantages produced by the smoother aerodynamic surfaces. They also added complexity and reliability issues.

By contrast, Gershenfeld said, “We make the whole wing the mechanism. It’s not something we put into the wing.” In the team’s new approach, the whole shape of the wing can be changed, and twisted uniformly along its length, by activating two small motors that apply a twisting pressure to each wingtip.

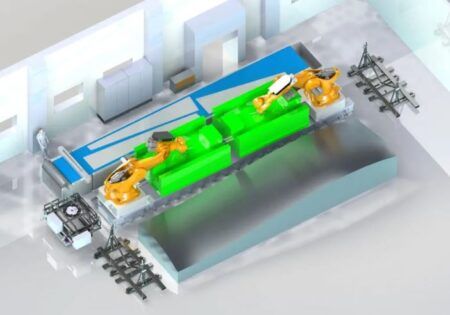

Building up a large and complex structure from an array of small, identical building blocks, which have an exceptional combination of strength, light weight and flexibility, greatly simplifies the manufacturing process, Gershenfeld explained. While the construction of light composite wings for today’s aircraft requires large, specialized equipment for layering and hardening the material, the new modular structures could be rapidly manufactured in mass quantities and then assembled robotically in place.

While exploring possible applications of this nascent technology, Gershenfeld and his team consulted with NASA engineers and others seeking ways to improve the efficiency of aircraft manufacturing and flight. They learned that “the idea that you could continuously deform a wing shape to do pure lift and roll has been a holy grail in the field, for both efficiency and agility,” he said.

Given the importance of fuel costs in both the economics of the airline industry and that sector’s contribution to greenhouse gas emissions, even small improvements in fuel efficiency could have a significant impact.

Wind-tunnel tests of this structure showed that it at least matches the aerodynamic properties of a conventional wing, at about one-tenth the weight.

November 9, 2016