A composites manufacturing research facility is to be built at Sheffield University in South Yorkshire, UK, with Boeing signed up as its first major research partner.

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) has secured £50 million ($US65 million) to establish the Compass (Composites at Speed and Scale) facility in Sheffield.

Compass will develop composite manufacturing solutions that are needed for future lighter commercial aircraft that are being developed to help the aviation industry reduce carbon emissions.

The new R&D center will be the AMRC’s largest-ever collaborative R&D program with founder and long-standing member Boeing. Spirit AeroSystems and Loop Technology are also partners.

A major aim of the center will be to reduce the time it takes to manufacture large aircraft components, from around 40 hours to four hours.

As part of the deal, Boeing has committed to procuring in excess of £2 billion (US$2.6 billion) of UK-manufactured goods for export per year to support the production of the company’s next civil passenger aircraft.

Steve Foxley, CEO at the AMRC, said, “Compass will help to establish South Yorkshire as the leading R&D centre of excellence in the manufacture of composites at speed and at scale, enabling future production capabilities that currently don’t exist.

“This facility will support and de-risk new technologies and processes, combining composites and digital technologies to help wider UK industry adopt more efficient, sustainable and cost-effective solutions for the production of future components, including the renewable, transport, defence and urban air mobility sectors.”

Boeing has worked with the Sheffield AMRC for more than 20 years. Maria Laine, president of Boeing UK, Ireland and Nordic region said, “This project is a testament to Boeing’s global commitment to drive innovation and growth within the local communities in which we are proud to live and work. Together with our world-leading industry partners, this investment is poised to revolutionize aerospace manufacturing to meet global demand, while supporting vital jobs and growth in the UK.”

As well as funding from local government and the University of Sheffield, Compass will be equipped through a £29.5 million(US$39 million) grant from the UK Government’s Aerospace Technology Institute (ATI).

Gary Elliott, CEO of ATI said, “The ATI investment in the Compass project will provide the UK aerospace industry with a path to proving new and advanced composite technologies, help develop world-first manufacturing capabilities and create an open-access facility for the broader benefit of aerospace and other industries. Alongside our support for Boeing’s IHSS project, this puts the UK supply chain in a competitive position to win production contracts for future next-generation aircraft.”

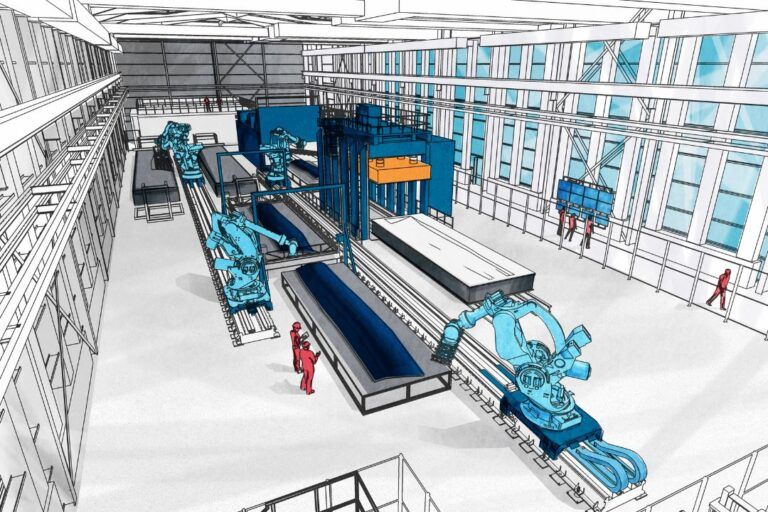

According to the Sheffield AMRC, Compass will enable the automation of layup of large-scale composite components by:

- Enabling run-at-rate demonstration of large-scale automated manufacturing processes.

- Developing precise pick and place and in-line inspection technologies to support tolerances required by aerospace.

- Developing a digital twin of the facility and process. This will allow industry to start development work virtually and support our existing research into virtual commissioning.

- Using fully-sensored processes and equipment, linked together in a flexible control architecture, providing a single source of truth for the validation of parts/processes, and enabling active control responding to changing process environments.

- Researching artificial intelligence and machine learning techniques for factory-scale process optimization.