Materials testing equipment company ZwickRoell has introduced two touch screen Rockwell hardness testing instruments.

The ZHR4150 and ZHR8150 provide either classic Rockwell or combined Rockwell and Superficial Rockwell hardness testing respectively. A Rockwell test measures the depth of penetration of an indenter under a large load compared to the penetration made by a minor load.

The hardness testers build feature touchscreen displays and support fast, accurate and efficient hardness testing across an extensive range of applications and industries, including aerospace.

The touchscreen interface has been designed with simple user experience as its guiding principle. Simplifying test setup parameters, testing procedures, and results handling all help to ensure the latest machines are efficient to use.

The machines also Incorporate the testXpert software, ZwickRoell users will already be familiar with, while a multi-language option ensures that users can work in a convenient language.

The ZHR interface is available in two variants, the basic interface on the ZHR4150 and advanced interface on the ZHR8150, both use 7in (18cm) full colour resistive touchscreens.

The basic interface stores the previous 20 test results, features automatic scale indication, multi-language support and the ability to output data to testXpert software, USB stick or computer. The more advanced interface accommodates data statistics and averaging, in & out of tolerance evaluation limits, automatic scale conversions and curvature corrections, histogram display, sample standard deviation display and calculation limits.

Both machine interfaces can integrate firmware updates in-situ by ZwickRoell service engineers.

The ZHR4150 provides all regular Rockwell scales, utilising precise spring force application. Supplied with the basic touchscreen user interface the ZHR4150 is the perfect blend of premium, reliable quality coupled with affordability. The ZHR4150 has the option for a factory-fitted upgrade to dead weight force application and this modification will also facilitate an upgrade of the firmware to the advanced firmware version.

The ZHR8150 combined Rockwell and Superficial Rockwell machine uses dead-weight force application to cover all scales. Supplied with the advanced touchscreen user interface, it provides premium features, usability, and quality into one package. The model can be upgraded to incorporate motorised automatic load change.

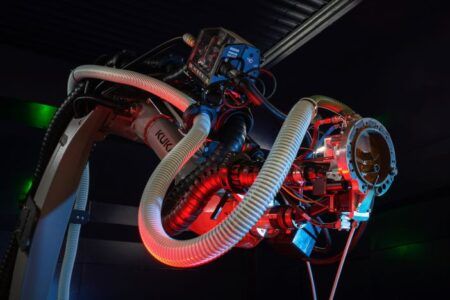

The innovative nose-mounted indenter on the ZHR range provides visibility for precise indentation location and accessibility for difficult to reach measurement points. Internal component surfaces can be tested without the need for additional machining and sample preparation.

Coupled with either one of the many anvil options, or a custom-designed test fixture, the ZHR range ensures that testing of almost any component is simple, rapid, and efficient. Both machine variants are available with an extended height workspace to accommodate large test specimens.

All machine variants are supplied with a UKAS calibration certificate with technical support readily available from the company and cost-effective routine maintenance and ongoing calibration can be provided by factory-trained engineers.