Researchers at the University of Arizona are using machine learning methods to monitor and mitigate defects that occur in the 3D printing processes used to produce parts for aircraft jet engines.

The research program, which is being funded by a US$750,000 from NASA funding, aims to mitigate and prevent defects that occur in additively manufactured metal parts designed for use in extreme environments.

Lockheed Martin Space and the 3D printing companies companies Open Additive and CompuTherm are working with Mohammed Shafae of systems and industrial engineering and Andrew Wessman of materials science and engineering from the University of Airzona .

“Andrew and Mohammed are using their combined backgrounds in materials science and systems engineering to look at additive manufacturing from a microscopic level all the way up to the large-scale systems level,” said David W. Hahn, Craig M. Berge dean of the College of Engineering at University of Arizona. “Advanced manufacturing is one of the college’s research focus areas, and this is a great example of an interdisciplinary effort to advance the field and keep the UA at the forefront.”

Unlike subtractive manufacturing, which involves carving an object out of a larger piece of material, additive manufacturing uses only the amount of material necessary to create a part. Precision and quality are key in additive manufacturing, especially when it is being used to create heat-resistant metal parts for applications such as jet engines, rockets or other high temperature environments.

Different defects present different problems

There are two broad categories of defects that can occur in additively manufactured products.

Process defects are physically visible aberrations that occur when something goes wrong in the printing process. For example, two layers may not stick together properly, or there could be a hole or crack in the material.

Material defects are variations in chemistry or the arrangement of atoms that are not visible except with high resolution microscopes. The complexity of many additively manufactured parts can make it difficult to find these defects using common inspection methods. Material defects may happen if one layer is still cooling, and another hot layer is placed on top of it. The temperature of the first layer could rise, and the change in the cooling process might alter the part’s properties. For example, the metal could become brittle, or less able to endure strain.

Shafae said, “You can think how dangerous that would be if the part were used in a jet engine or a rocket. The types of defects we’re focused on are defects that will make the material behave differently than intended.”

Machine learning

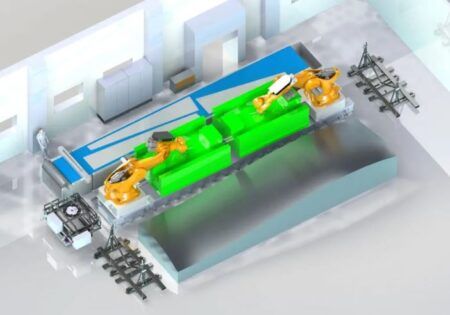

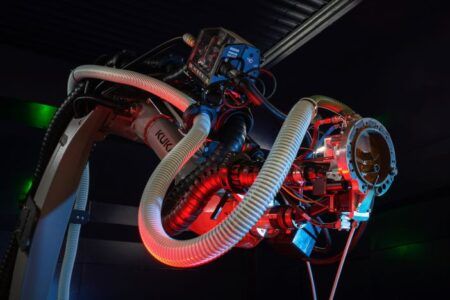

The researchers are using a sophisticated sensor system, combined with thermal imaging cameras and high-speed localized cameras to monitor the 3D printing process and identify when and where defects occur.

They plan to apply machine learning methods to the data and develop a model that can predict defects when they occur. This will allow scientists to take corrective action to prevent the defects or terminate a process before wasting more time and materials. Research in this area typically uses a single type of sensor to detect specific categories of defects, but this work takes the concept a step further.

“We’re really going to try to learn how these separate categories of defects can be linked to each other, because sometimes the process defects can be the leading cause of the material defects,” Shafae said.

“This is truly an example of what people need to be doing to get to Industry 4.0, which is basically the use of data to improve processes, and ensure they are performing as you want them to,” Wessman said. “By improving manufacturing process quality, you can know what you have is a good product from the time you take it out of the machine.”