Blended wing body aircraft developer Natilus has begun the site selection process for its first factory as it continues to build the first full scale prototype for its Kona regional cargo aircraft.

The San Diego, USA-based company is looking to build a 250,000-square-foot factory capable of making 60 Kona blended wing body (BWB) freighters per year. The factory will employ more than 300 workers and be in the USA.

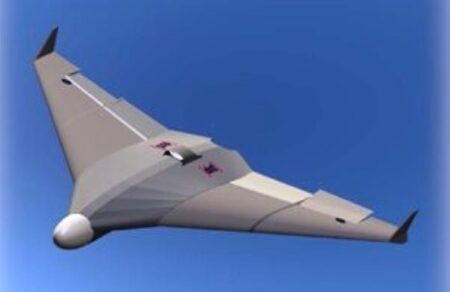

Kona is a Part 23, 19,000 lbs (8,600kg) piloted aircraft with an 85ft (25m) wingspan and a 1000 mile (1600km) range. Natilus is aiming for Kona to use 30% less fuel and produce 50% less carbon emissions than similar aircraft while providing 40% more volumetric capacity. It will be powered by two Pratt & Whitney PT6 turboprop engines.

Natilus is currently building the first full scale Kona prototype at its facility in San Diego and is working towards first flight in 24 to 36 months. The company has been flying a sub-scale model of the Kona since 2023

The company aims to deliver the first Kona cargo aircraft by early 2028 before it starts producing a commercial passenger BWB aircraft – the 200-seat Horizon. A different 2.5 million square feet factory that will employ around 3,000 people is planned to make Horizon.

Natilus said it is prioritizing regions of the USA with strong incentive programs and runways, airspace clearance for testing, training, and selloff facilities, as well as proximity to suppliers and transportation for the Kona factory site. The company expects to announce further details in the coming months.

“A lot of carbon fiber manufacturing is manual so we are looking for locations not just with the talent we need, but also with the labor rates that will enable us to meet our production goals in terms of cost. There is maybe four or five states that make the most sense,” said Aleksey Matyushev, co-founder and CEO of Natilus.

Natilus was founded in 2016 and employs 20 people in San Diego, California. Despite being devised several decades ago and offering capacity advantages, a BWB-shaped aircraft has never been successfully developed and deployed commercially. Issues around flight stability and passenger comfort have been barriers to the use of the BWB design.

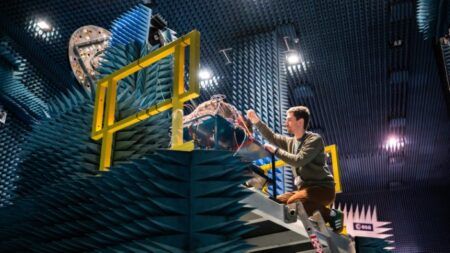

As well as using data from previous projects such as NASA’s X-48, the company has conducted three wind tunnel tests to help solve stability and control challenges.

“Our second and third wind tunnel tests were phenomenal. As far as performance data and stability control go, we are stable in each axis, which means we don’t need a complex and expensive fly-by-wire system,” said Matyushev. “There’s a lot of analysis tools, specifically computational fluid dynamics, that have evolved a lot over the last 10 to 15 years. We’re using automated tools all in the cloud. Artificial Intelligence is helping us solve a lot of these challenges. In terms of the mathematical problems and the speed we can move at has been amazing

“At the same time, we’re taking a lot of care in fitting into existing infrastructure, specifically apron spaces. From my perspective, we have figured out the technology, we are on to getting the aircraft into the air and the operational side.

Horizon is being pitched as a competitor in the Boeing 737 and Airbus A320 narrowbody segment. Natilus has more than 560 pre-orders, with 400 of those for Kona.

The latest customer to have reserved production slots is Canada’s Nolinor Aviation.

Matyushev said, “A lot of the big industry players have started to falter – innovation has stagnated. Next generation narrow bodies won’t be delivered until the late 2030s, mid 2040s and it seems like they’re all going to look mostly the same.

“Airlines must start thinking about sustainability and economics and to achieve their goals we need to look at what we can do outside of the engine with the airframe. Product differentiation has also become a really important factor for airlines too.

“Finally people are sick and tired of the duopoly. They’re willing to take a risk on new manufacturers with new ideas and concepts.”