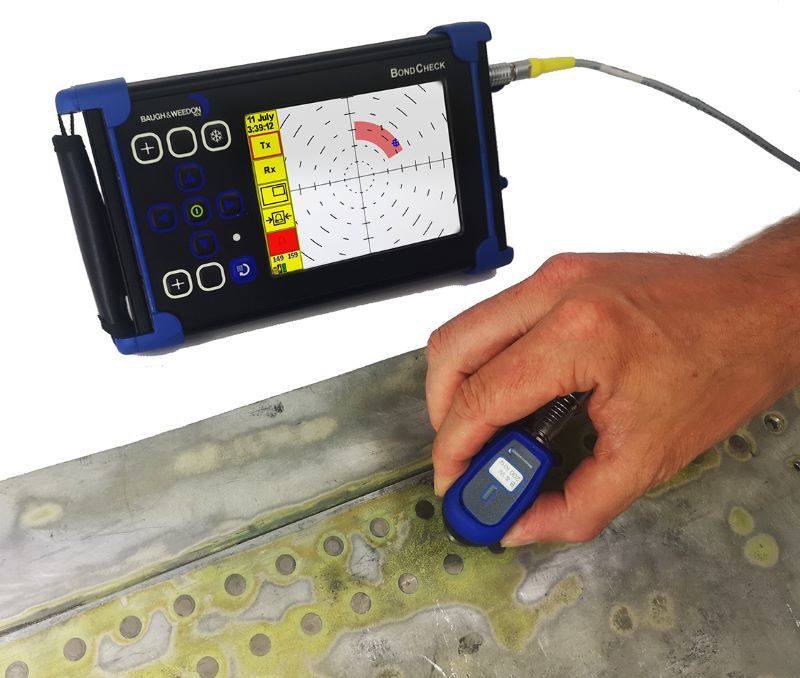

Baugh & Weedon’s BondCheck can check anything bonded together using adhesive – composites with composites, composites with foam cores, composites and metal.

It can inspect bonds in pitch-catch or resonance modes, or mechanical impedance analysis (MIA). Example applications include those where carbon and metal honeycombs need to be inspected for delaminations, dis-bonds and core damage as well as small defect detection and dry coupling.

The BondCheck uses well-understood flaw-detecting technology, developed for use in today’s aerospace industry. A high-frequency pulse of sound is transmitted and received from the probe. The sound is a higher frequency than, for example a tap test, but lower than is used in ultrasonic testing.

“It is a comparison technique – you always need a good example to compare your test to, but it will identify any type of dis-bond, in composites or even in metal structures with multiple layers,” says Pete Burrows, sales director at Baugh and Weedon.

Some companies have not kept up with advancements in material technology and are unaware of how inspection techniques have progressed in recent years. UK-based Baugh & Weedon can supply bond testing instruments immediately and is investing in R&D to improve the multi-mode bond testing device.

“We are seeing a lot of increase in the BondCheck’s use for in-service inspections of aircraft. There are now more aircraft in service that use more composites in their construction and it is being used to inspect impact damage,” says Burrows.

While the BondCheck is traditionally has been best suited to checking smaller, complicated or hard-to-reach areas of aircraft, work is underway to automate the testing and recording process. This will open up its use for other applications. “Automating bond checking makes it a viable technique for scanning larger areas,” says Burrows.

Detecting difficult defects

Weighing just 1.2kg, the BondCheck offers three different modes: pitch-catch, resonance modes, or mechanical impedance analysis (MIA). Users can configure color schemes and use a secondary pane to create a split display with a choice of X-Y spot, frequency sweep, RF Waveform of spectrum displays.

The pitch-catch probe has interchangeable hard wearing tips with rounded and flat profiles available. The probe is broadband and is suitable for a wide range of applications. Resonance probes are available in frequencies between 60 and 350kHz, and can also be supplied as a multi-probe kit.

Both probe types have an Alarm LED and digital ID for ease of use, settings can be stored and “air calibration” is possible to establish the most sensitive inspection frequencies for your inspection.

The MIA technique is particularly useful for small defect detection, using a dry coupled probe with a small contact area. The technique offers excellent near surface defect sensitivity and is particularly suitable for top surface skin to core dis-bond detection for composite as well as metallic honeycomb structures.

“MIA and pitch and catch are dry-bonded, which is useful in aerospace – unlike ultrasound testing which requires liquid,” says Burrows. “The BondCheck is good at finding some defects that are tough to find with other techniques. For example, it can detect defects inside a honeycomb panel from the far side of the panel.

“It is simpler and faster to setup and calibrate than similar devices on the market, users require less training,” he adds.

R&D advances

Baugh & Weedon plans to support the devices for the foreseeable future and is investing in improving the technology the BondCheck uses in several ways.

“We are the only company still actively developing the technology, with a PhD researcher working on improving the pitch and catch technique,” says Burrows.

Baugh & Weedon are also working with sister company Pragma NDT on ways to integrate scan data from the BondCheck into 3D models. Burrows believes this has the potential to revitalize interest in the technique.

“The technology stagnated because it could not map results digitally. Being able to visualize the data in 3D brings bond checking to the forefront of NDT 4.0” he added.

As well as enabling the easier scanning of larger areas, automation of bond checking also opens up more applications on the factory floor by fitting probes on to robots or cobots.

“Bond checking is catching up with the advances that have been made in the area of composite materials,” Burrows says. “This technology is evolving into an NDT 4.0 device that can record and store results and build a proper picture with digital datasets.”

Founded in 1967 Baugh & Weedon also offers a range of Magnetic Particle and penetrant- inspection systems, Ultrasonic (UT) Thickness Gauges, UT Flaw Detectors, Ultrasonic Wall Crawlers, Hollow Rail Axle Inspection Sytems, UT Immersion Tanks, Eddy Current (ECT) Sorting Bridges.