In the ongoing effort to reduce development and testing times for aerospace parts, an accurate simulation model and new advanced measurement and validation technologies. Even with more stringent requirements, engineers must have a system that is fast and easy to use while still measuring the direct mechanical response without surface treatments or the need to compensate for mass loading.

This is made more difficult since tests regularly must be done under extreme conditions at high frequency and high resolution to be certain of the results. These are challenging constraints and to highlight the future of testing we will focus on three particular applications where new innovative techniques can be used.

Many critical aerospace components are made in materials and shapes that will be subjected to high loads during their lifetime. In order to ensure safety, new methods for measuring dynamic stress and strain have been developed. Knowing the distribution of this strain is the key to understanding and increasing the durability of components under dynamic load.

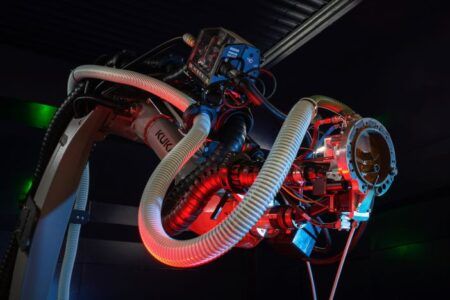

Utilizing a Polytec 3D Scanning Vibrometer, many measurements have been made highlighting this distribution on typical items such as: turbine blades, tensile test samples, and materials under high temperatures.

As the industry continually pushes the boundaries with new materials, there is a strong need to increase the cycle counts during ultrahigh cycle fatigue tests to come closer to the parts endurance limit. This creates a problem as the current testing methodology for measuring 10,000,000 cycles takes over four days. Raising this to the needed 1,000,000,000 cycles would make the test time over a year.

In order to shorten the test time, Polytec has developed a technique that brings it down to a few days. This is done without the limitations of the current technique which involve high instrumentation efforts, limited spatial resolution, mass loading, sensitivity to mounting errors, lack of capability to test at high temperatures and a limited cycle count. Utilizing the Polytec3D Scanning Vibrometer makes it possible to measure one billion cycles in a matter of days.

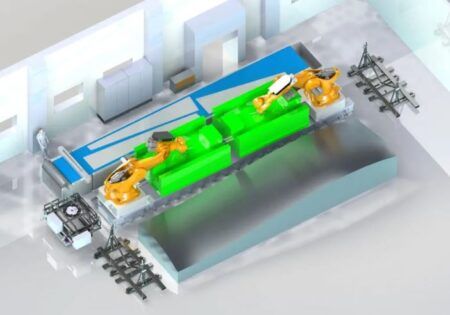

While the above two examples exemplify challenges directly related to safety, other factors are making even conventional tests more difficult. Minimizing prototype expense is required to stay competitive. Add to that the push for hypersonic travel, where mechanical and thermodynamics can both dominate a structure requiring a complex multi-physics approach with more assumptions than ever in the analytical model, and critical modal analysis testing must evolve.

The classic approach using a few sensors and points is not enough. This testing is made more demanding with complex non-linear structures and the net results are that historical contact methods of modal analysis are not enough to draw the appropriate conclusions. A high resolution data set directly verifying the simulation proves safety, reliability and performance as needed.

As illustrated in the above three applications, the ever-growing push for increased performance causes the interaction between test and simulation to be crucial for a cost effective design process while maintaining safety and reliability.

This article was provided by Polytec