Individual parts from retired fighter jets have been ground down and 3D printed into new components for use in the UK’s next generation of military aircraft.

The Royal Air Force’s (RAF’s) recycling program turns parts from old Tornado aircraft into powered metal, which is used to 3D print components for Tempest jets.

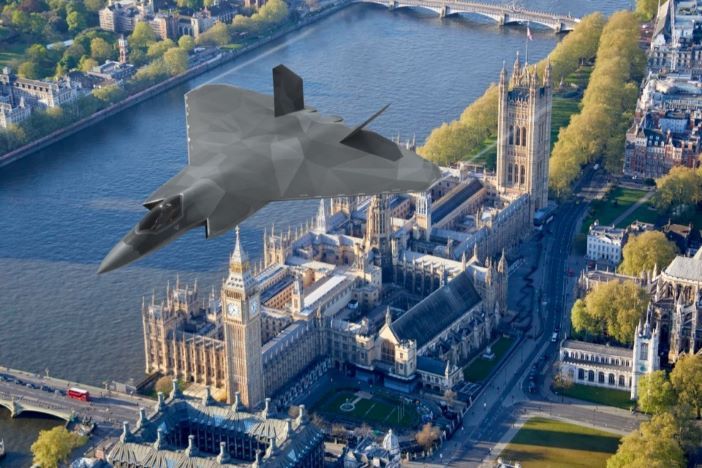

The UK, Japan and Italy are developing the next-generation combat Tempest aircraft for the Global Combat Air Programme (GCAP). Tempest will be part of a wider combat air system that will use new technologies to respond to increasingly high-tech and complex threats.

Tempest is planned to enter service in 2035 and replace the Typhoon fighter jet. The first test flight of a demonstrator is planned for 2027.

The GCAP was first announced in December 2022. However, teams at companies such as BAE Systems, Leonardo UK, MBDA UK, Rolls-Royce have been working on the aircraft since 2018.

The recycling program will save costs, reduce the reliance on global supply chains of critical and high value metals and produce components that are lighter, stronger, and longer lasting than those made through traditional forging techniques.

Many of the Ministry of Defence’s (MOD’s) surplus assets contain strategic metals, including high quality steel, aluminum, and titanium. The Tornado 2 Tempest project team have been identifying whether some of these components could be atomised into powders – known as “feedstock” – for additive manufacturing to make new parts.

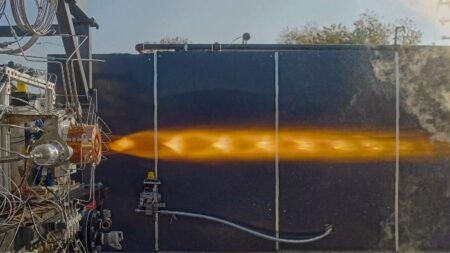

Tornado parts containing titanium, including jet engine compressor blades from a low-pressure air compressor, were selected. They were cleaned, successfully atomized and recycled into a 3D printed nose cone and compressor blades by Additive Manufacturing Solutions (AMS) for Orpheus – Rolls-Royce’s small engine concept that is part of the MOD’s Future Combat Air System (FCAS) program for delivering Tempest.

The nose cone was fitted onto an Orpheus test engine and passed suitability and safety checks, demonstrating the technique has potential use in sixth-generation jets such as the Tempest.

Maria Eagle, the UK Government Minister for defense procurement and industry said, “By working with key industry partners, we can ensure our Armed Forces have the very best kit to keep our country safe. Not only does this initiative have a positive impact on the environment and national security, it supports the domestic defence industry acting as an engine for growth.”

Andrew Eady, vice president of FCAS Sustainability at Rolls-Royce said, “The Tornado 2 Tempest project exemplifies the forward-thinking sustainability principles embedded in the FCAS Sustainability Strategy and MoD Defence Support Strategy.

“This project is bold, exciting and innovative, and a demonstration of exemplary collaboration between the MoD, industry and SME, furthering the drive for circular economy practices and innovative digital enablers in Defence.”

Robert Higham, director of AMS said, “This project turned our proposed solutions into a reality, and we have been very humbled and grateful to the MOD and Rolls Royce for allowing us to showcase our capability to deliver game-changing circular economy processes and parts in Defence.”